Calculation and rational utilization method of fly ash resource utilization theoretical model

A theoretical model and resource-based technology, applied in the field of fly ash reuse, can solve the problems of secondary pollution and environmental risks, difficult application technology, etc., and achieve the effects of significant social and economic benefits, easy promotion, and no environmental risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

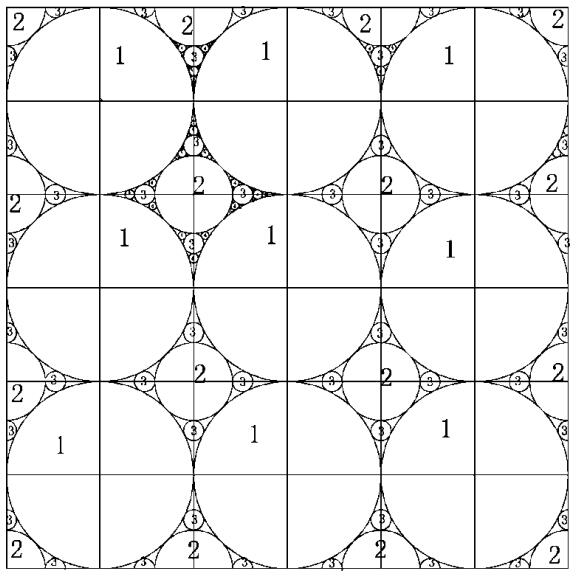

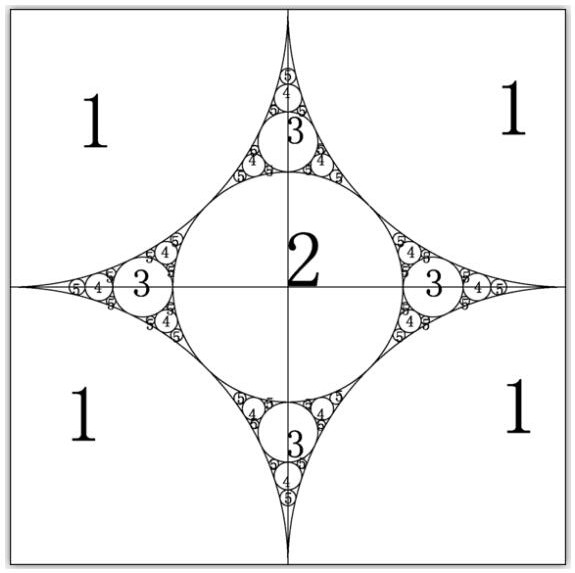

[0099] The fine aggregate of solidified fly ash powder, with a particle size of 0.9mm to 0.075mm and below, is mixed into the concrete. The theoretical basis is that there are certain gaps between the particle gradations of the concrete, and the general commercial concrete is continuous. Grading, the grading of concrete with different grades is mostly different, and the void volume is also different. In order to scientifically mix the pulverized solidified fly ash fine aggregate into concrete in a certain amount, the size and distribution of voids in each cubic meter of concrete should be quantified first. By establishing a theoretical model, analyzing the size of concrete voids per cubic meter, and quantifying the proportion of voids in concrete. For example: C30 concrete has gaps of different sizes per cubic meter, and 5.0% to 8.0% of fly ash raw ash particles are selected to be mixed into the concrete.

[0100] The test shows that the fly ash particles with a median partic...

Embodiment approach 2

[0115] Change the continuous gradation of C30 concrete to a discontinuous gradation to obtain more voids in the concrete and absorb as many harmless solidified fly ash particles as possible, which can increase the solidified fly ash particles in the concrete. The dosage in concrete without reducing the strength and durability of concrete. E.g:

[0116] Dosage form: cement + admixture Ⅰ dosage: solidified fly ash particle dosage = ZⅠ: 12%: 10%.

[0117] The 28d strength of the prepared concrete is 44.1MPa~48.7MPa.

Embodiment approach 3

[0119] Application in highway road base.

[0120] 1) The mix ratio of the base course under the road:

[0121] Cement + admixture Ⅰ: fly ash: stone chips: gravel: water = 3.0%: 10%: 49%: 30%: 8.0%. The 7d immersion strength of the prepared concrete is ≥4.5MPa.

[0122] Cement + admixture II: fly ash: stone chips: gravel: water = 3.0%: 10%: 49.0%: 30%: 8.0%. The 7d immersion strength of the prepared concrete is ≥6.2MPa.

[0123] 2) Base mix ratio on highway road:

[0124] Cement + admixture Ⅰ: fly ash: stone chips: gravel: water = 4.0%: 10%: 48.0%: 30%: 8.0%. The 7d immersion strength of the prepared concrete is ≥5.5MPa.

[0125] Cement + admixture II: fly ash: stone chips: gravel: water = 4.0%: 10%: 48.0%: 30%: 8.0%. The 7d immersion strength of the prepared concrete is ≥7.5MPa.

[0126] In the lower base course of the cement stabilized layer of highway roads, the general cement content requirement is 3%, and the 7d immersion strength of the prepared concrete is ≥ 2.5MP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com