Wastewater sludge recovery treatment device

A technology for recycling and sludge treatment, applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/concentrated sludge treatment, etc., can solve problems affecting filtration efficiency, stability, and slow sludge recovery efficiency , to achieve the effect of improving precipitation efficiency, reducing temperature loss and improving mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

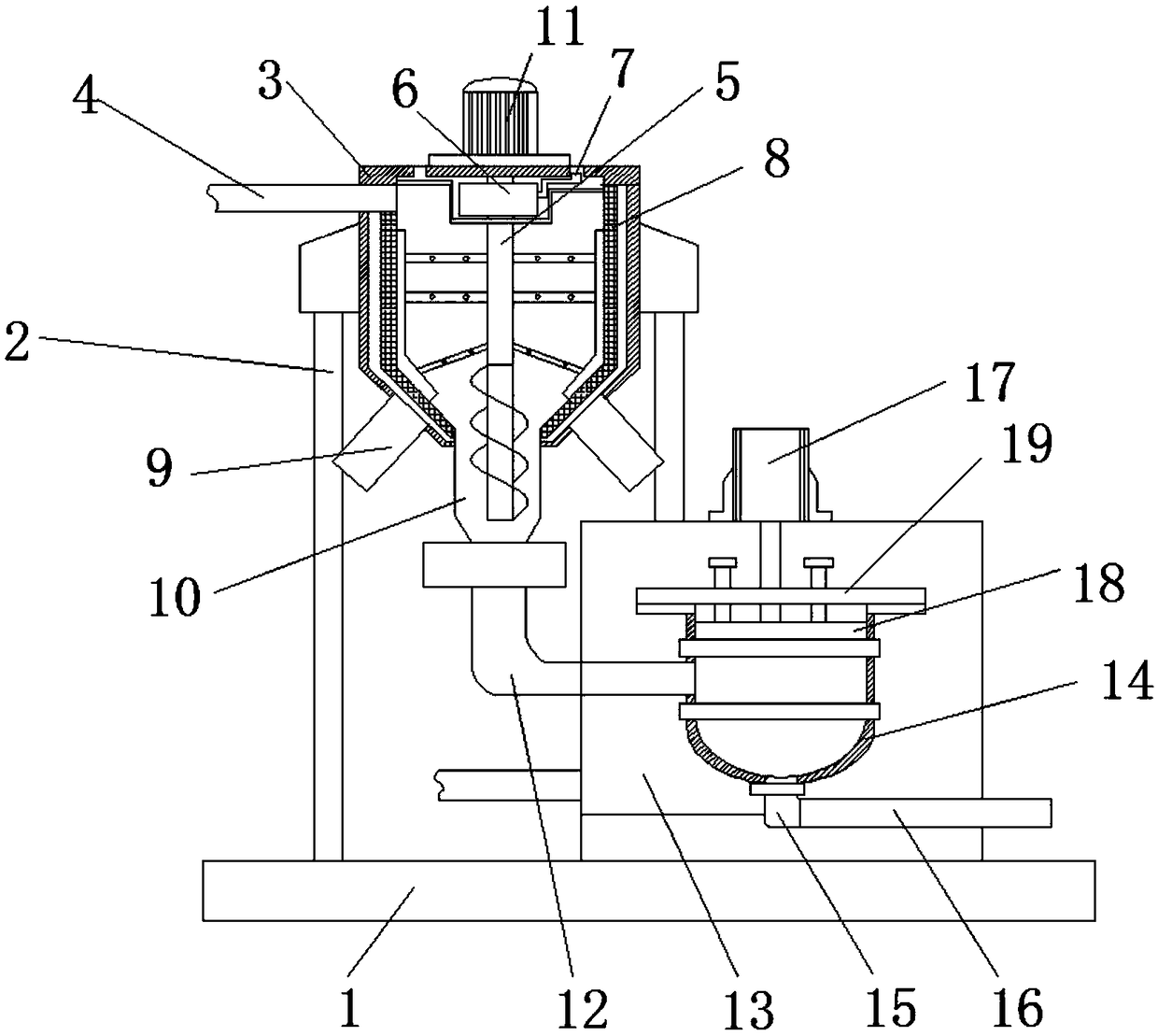

[0025] Embodiment one: refer to Figure 1-4 , a waste water sludge recovery treatment device, including a base 1 and a sludge recovery bin 3, the base 1 is fixed with a sludge recovery bin 3 through a pillar 2, and a sewage inlet pipe 4 is connected to the side wall of the sludge recovery bin 3, The first drive motor 11 is fixed to the center of the top of the sludge recovery bin 3 by bolts, and the bottom of the first drive motor 11 is connected to the stirring shaft 5 in rotation. The inside of the sludge recovery bin 3 is fixed with a filter cover 8, and the bottom of the sludge recovery bin 3 An outlet pipe 9 is connected to the outer wall, a first mud discharge pipe 10 is connected to the center of the bottom of the filter cover 8, a dewatering box 13 is fixed on the side of the sludge recovery bin 3 on the base 1, and a dewatering box 13 is fixed inside the dewatering box 13. Press filter tank 14, the top bolt of press filter tank 14 is fixed with sealing cover plate 19,...

Embodiment 2

[0026] Embodiment two: refer to Figure 1-2 , the stirring shaft 5 is sleeved and fixed with a flocculant box 6, and the flocculant box 6 is conductively connected with the stirring shaft 5, and the flocculant box 6 is connected with a feeding pipe 7, and the stirring shaft 5 is welded with a scraper through the stirring rod 20 Plate 21, the stirring rod 20 is provided with a liquid outlet 22, the bottom end of the stirring shaft 5 is connected with a screw feeding rod 23, and the screw feeding rod 23 is located inside the first mud discharge pipe 10, the stirring shaft 5 and the stirring plate 20 are all internal hollow structures, and the stirring shaft 5 and the stirring rod 20 are connected to each other, the flocculant in the flocculant box 6 can be transferred to the stirring rod 20 through the stirring shaft 5, and the liquid outlet hole 22 opened on the stirring rod 20 The discharge is mixed with the sewage, and the auxiliary stirring by the stirring rod 20 effectively...

Embodiment 3

[0027] Embodiment three: refer to figure 1 and image 3 , the pressure plate 18 is welded with a limit shaft 24 that runs through the sealing cover plate 19, and the top end of the limit shaft 24 is welded with a limit block. There are three limit shafts 24, and the three limit shafts 24 are arranged in a ring shape. The spacing between the two adjacent limit shafts 24 is equal, and the outer wall of the pressure filter tank 14 is sleeved with a ring frame 25. The limit shaft 24 is used to limit the position of the pressure plate 18, which improves the stability and stability of the pressure plate 18 moving up and down. 18, the setting of ring frame 25 is used to improve the intensity of pressure filter tank 14.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com