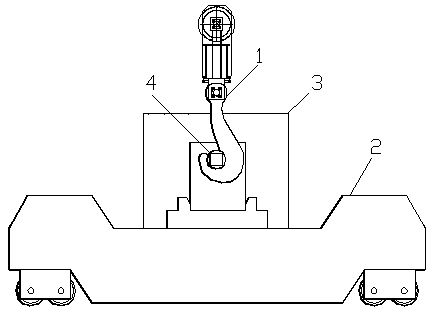

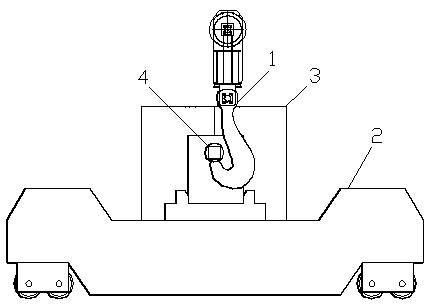

Plate hook and quick lifting method thereof

A technology of plate hook and hook body, which is applied in the direction of load hanging components, transportation and packaging, safety devices, etc., can solve the problems of inability to hook safely, accurately, and efficiently, and achieve convenient adjustment of installation angle, convenient replacement and maintenance, and saving The effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

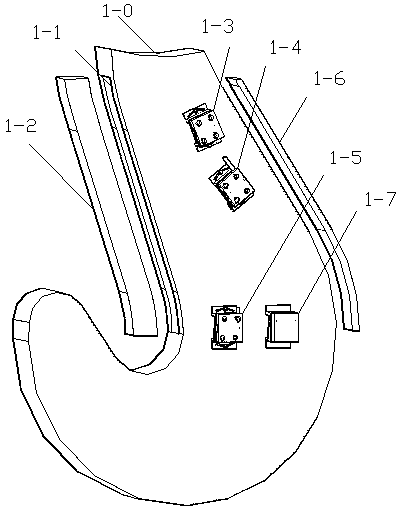

Embodiment 1

[0029] Embodiment 1: see Figure 3-7 As shown, a plate hook 1 includes a hook body 1-0, a magnetic strip 1-2, a photoelectric sensor 1-3, a camera 1-4, a proximity switch 1-5, a high temperature resistant light strip 1-6, and a battery pack 1 -7 and so on. A groove 1-1 with a width of 1 / 3 of the thickness of the plate hook is provided on the inner wall between the half of the vertical height of the hook body 1-0 and the tangent point between the inner wall of the hook body and the hook center circle, and the groove 1-1 is nested Magnetic strips 1-2 made of NdFeB permanent magnets are installed. A photoelectric sensor box 1-8, a camera box 1-9, a proximity switch box 1-10 and a battery pack box 1-11 are sequentially installed on the outside of the hook head of the hook body from top to bottom. Photoelectric sensors 1-3, cameras 1-4, proximity switches 1-5, and battery packs 1-7 are respectively nested and installed in various boxes. On the outer wall of the hook body 1-0, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com