Rotatable lifting type pneumatic clamping device

A technology of rotary lifting and pneumatic clamping, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of operator's personal safety threat, high physical strength requirements of porters, inability to rotate and move up and down, and achieve simple and practical structure. Strong, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

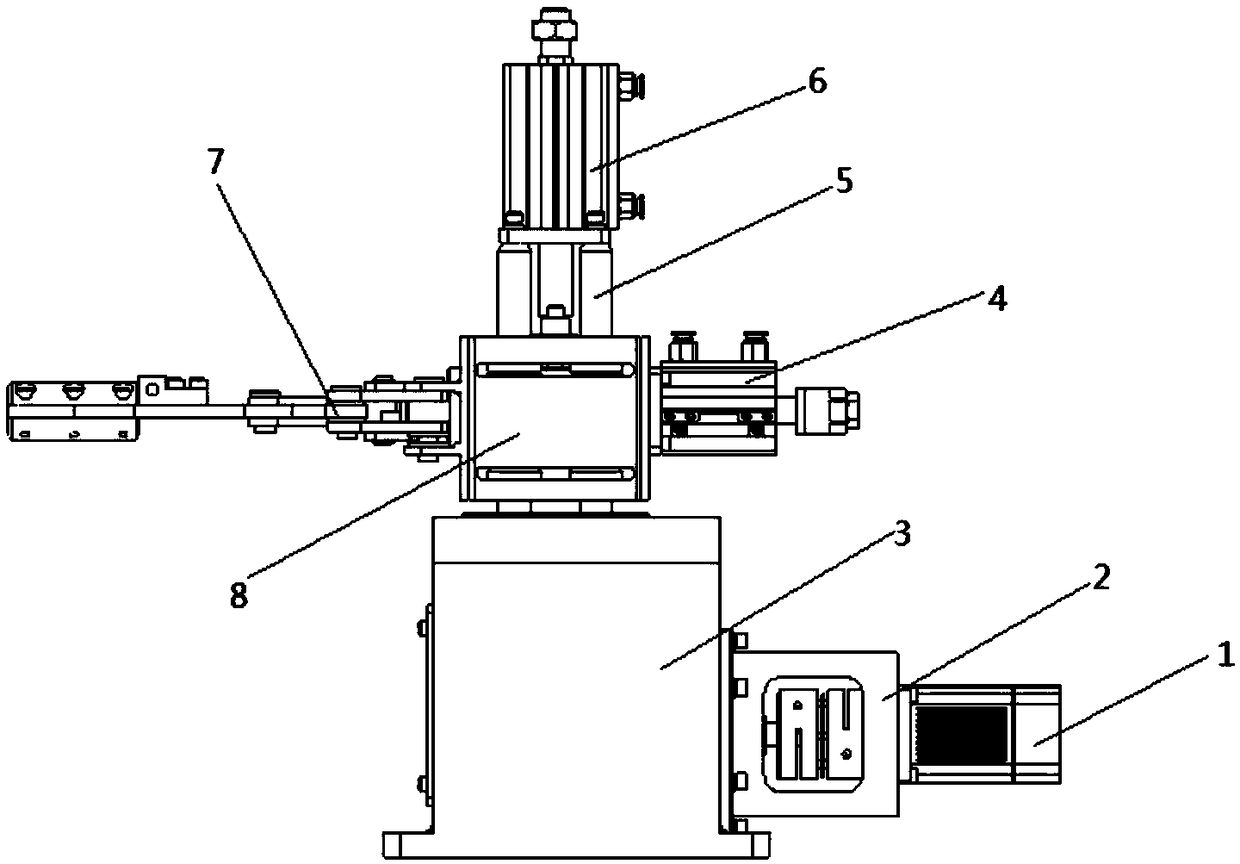

[0031] Such as Figure 1-3 As shown, a rotatable lifting pneumatic clamping device according to the present invention includes a helical gear shaft 11, a stepped shaft 25, a second helical gear 27, a first box body 3, a second box body 8, and a first cylinder 4. Guide rail rod 5, second air cylinder 6 and clamping mechanical arm 7. The helical gear shaft 11 is coaxially provided with a first tapered roller bearing 13, a second tapered roller bearing 14, a first neck flange 29 and two first snap rings 12, the first tapered roller bearing 13 and the second The tapered roller bearings 14 are installed symmetrically, the first tapered roller bearing 13 is axially positioned by two first snap rings 12, the second tapered roller bearing 14 is positioned by the shoulder on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com