Grain silo for feeding along side wall

A silo and grain technology, applied in the field of grain silos, can solve the problems of damage, high grain falling speed, etc., and achieve the effect of slowing down the falling speed and reducing grain breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

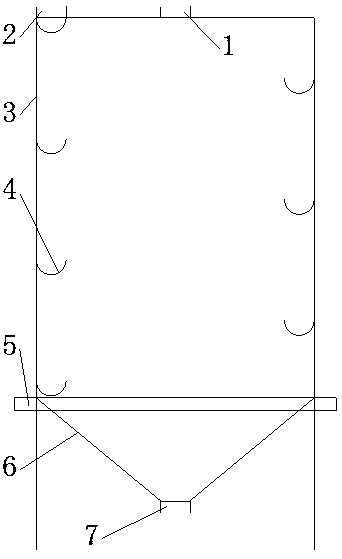

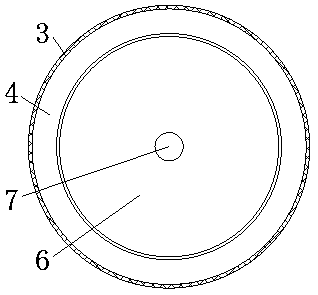

[0013] Such as Figure 1-2 As shown, a kind of grain silo that feeds along the side wall provided by this embodiment includes a silo body 3 and a spiral groove plate 4, the top of the silo body 3 is provided with a feed port for grain feeding, and the silo body 3 The bottom of the silo is provided with a cone bucket 6 for assisting grain discharge. The spiral groove plate 4 surrounds the inner wall of the silo body 3 in a spiral shape from top to bottom. The cross section of the spiral groove plate 4 is semicircular so that the surface of the spiral groove plate forms The conveying trough for grain, the conveying trough spirally extends downwards from the feeding port to the bottom of the silo body 3 .

[0014] Wherein, the silo body 3 is fixed by the base frame 5, which is a general basic support frame for the silo configuration, and will not be described here again.

[0015] The central position of the cone bucket 6 is provided with a discharge port 7 for grain, and a gate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com