Egg automatic packing machine

A cartoning machine and automatic technology, applied in the field of automation, can solve the problems of high cost, laborious and labor-intensive, and the farm cannot afford it.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

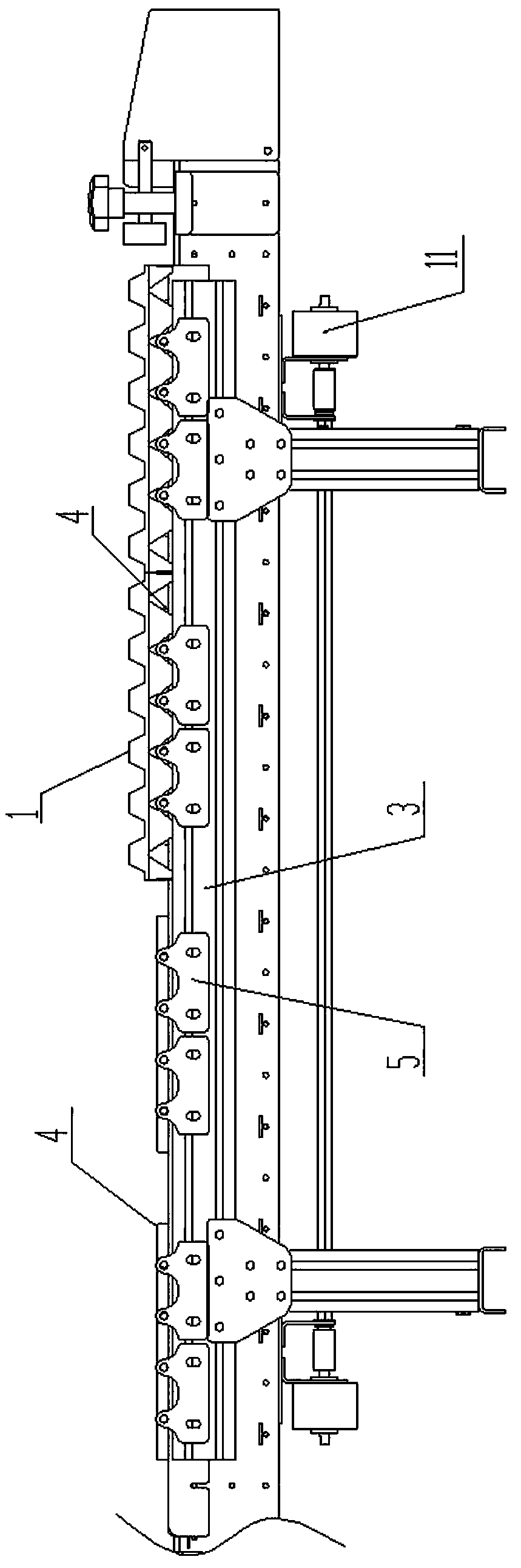

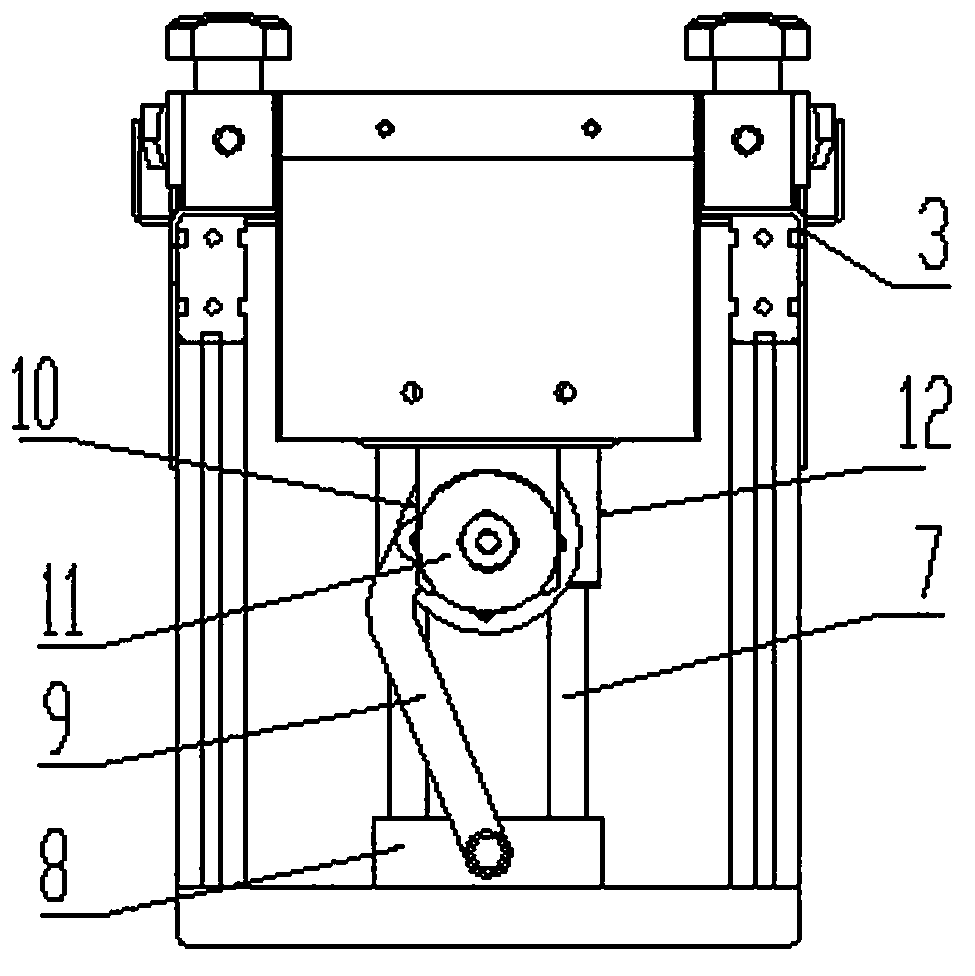

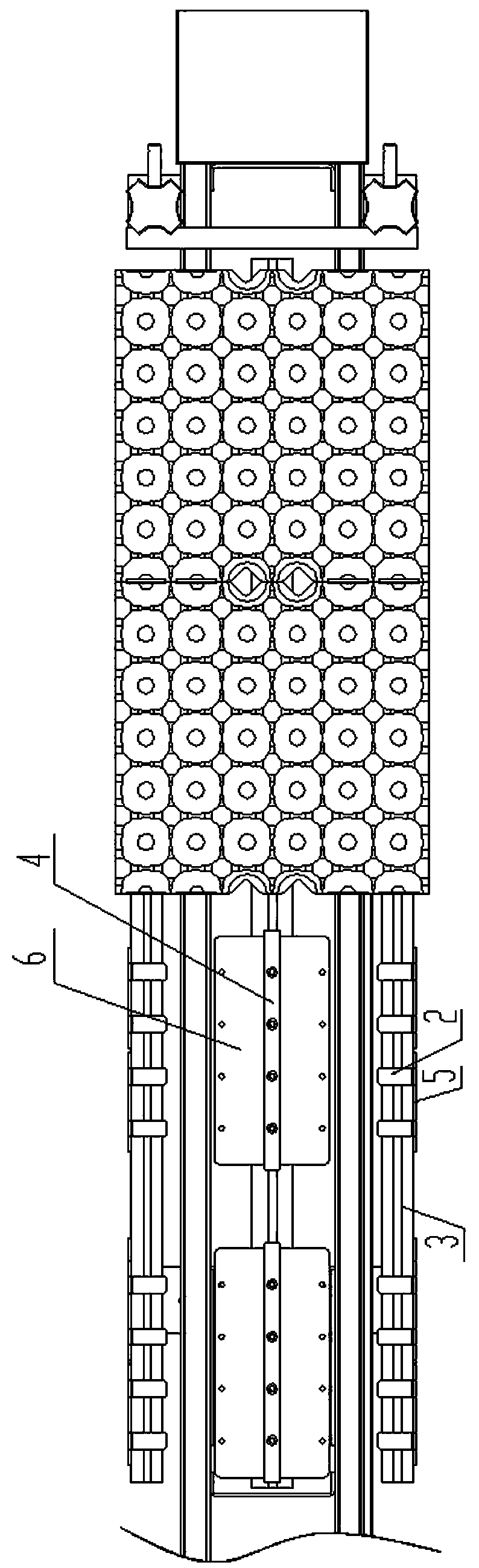

[0036] For the convenience of explanation, the following is combined with the Figure 1-18 , explain in detail the invention of the egg automatic packing machine.

[0037] An automatic packing machine for eggs, comprising an egg tray conveying unit 101 , an egg tray positioning unit 102 , an egg tray grabbing unit 103 , a grabbing head rotating unit 104 and a case erecting unit 105 .

[0038] The conveying unit is a conveying platform arranged horizontally, and the end of the conveying platform is provided with an egg tray positioning unit including a positioning rod arranged on the conveying platform 3, and the positioning rod comprises a fixed positioning rod 2 positioned at the edge of the conveying platform 3 and a positioning rod located at the edge of the conveying platform 3 The mobile positioning rod 4 at the center of the conveying table 3, the mobile positioning rod 4 moves upwards, and stretches into the groove at the bottom of the egg tray 1 to complete the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com