Cover installation structure for mineral water bucket

A mineral water barrel and capping technology, which is applied in packaging and other directions, can solve the problems of low capping efficiency and long time consumption, and achieve the effects of short capping time, ensuring press-fitting efficiency, and high capping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

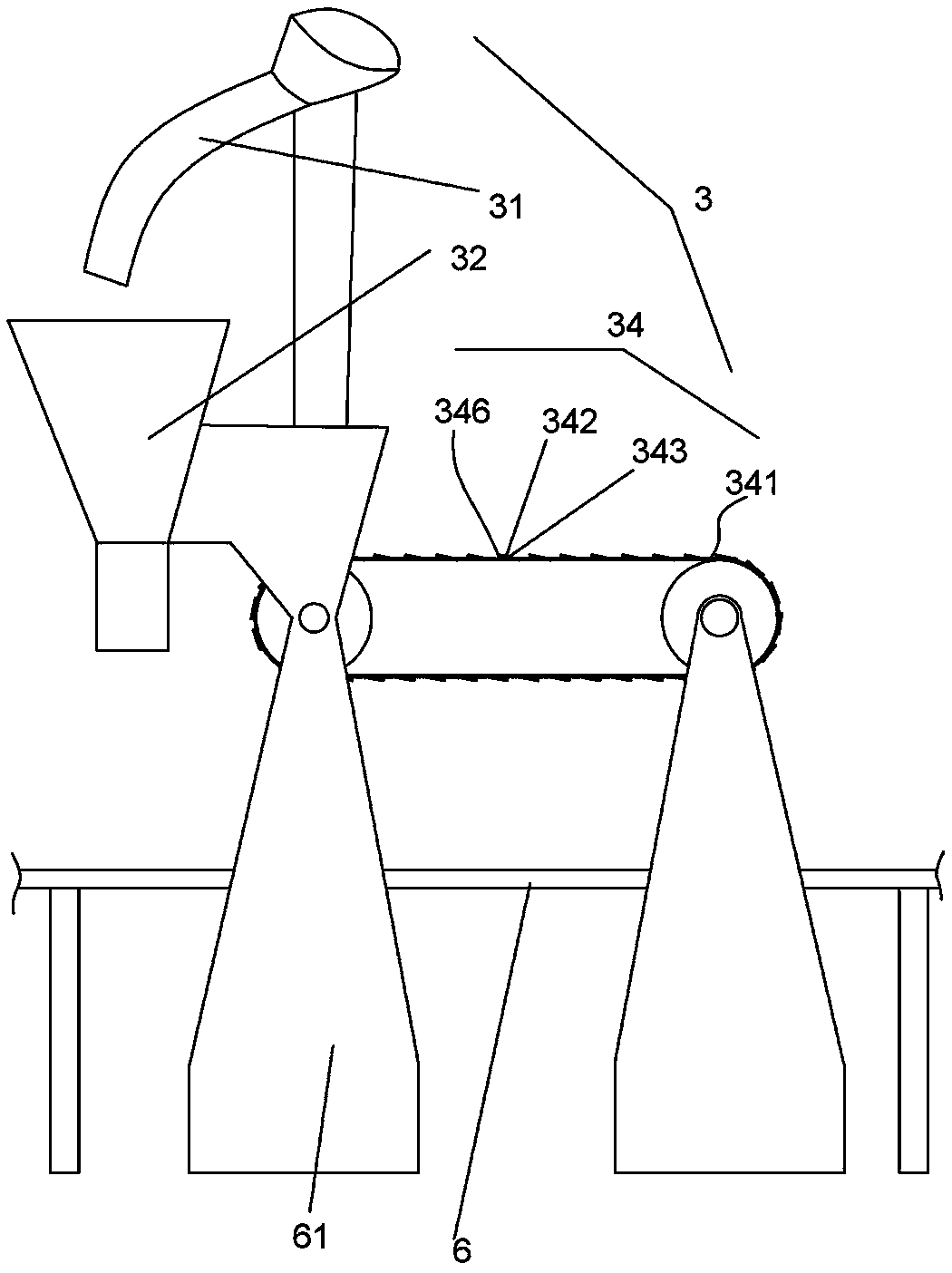

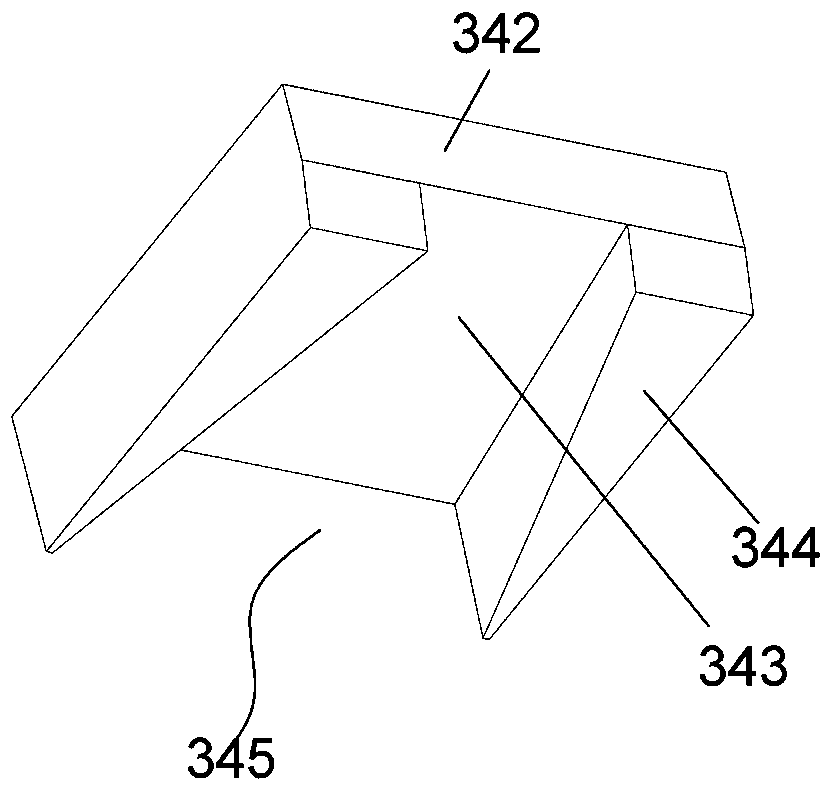

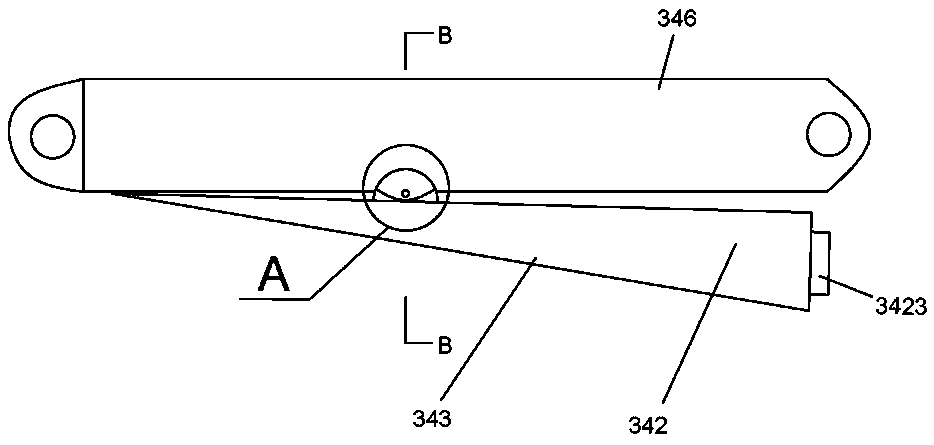

[0022] Such as figure 1 As shown, a mineral water bucket capping structure includes a second bucket conveyor belt 6, an upper cover assembly 3 that is used to cover the bucket after watering is located above the second bucket conveyor belt 6; The lid assembly 3 includes a vacuum suction delivery pipe 31, a bung storage bucket 32 communicating with the vacuum suction delivery pipe 31, and a press-fitting mechanism 34. The press-fitting mechanism 34 includes a rotating belt 341 connected by a plurality of chain plates, The pressing plate 342 disposed on each of the link plates has an oblique pressing surface 343 . During installation, rotating belt 341 can be installed on a pair of power wheels of frame 61, and rotating belt 341 is positioned at the top of described second bucket conveyer belt 6, is driven to rotate by this power wheel, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com