Intelligent monitoring system for corrugated board warpage and method thereof

A technology for corrugated cardboard and intelligent monitoring, which is applied to chemical instruments and methods, lamination devices, and control lamination, etc., which can solve the problems of corrugated cardboard warping information lagging and equipment debugging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

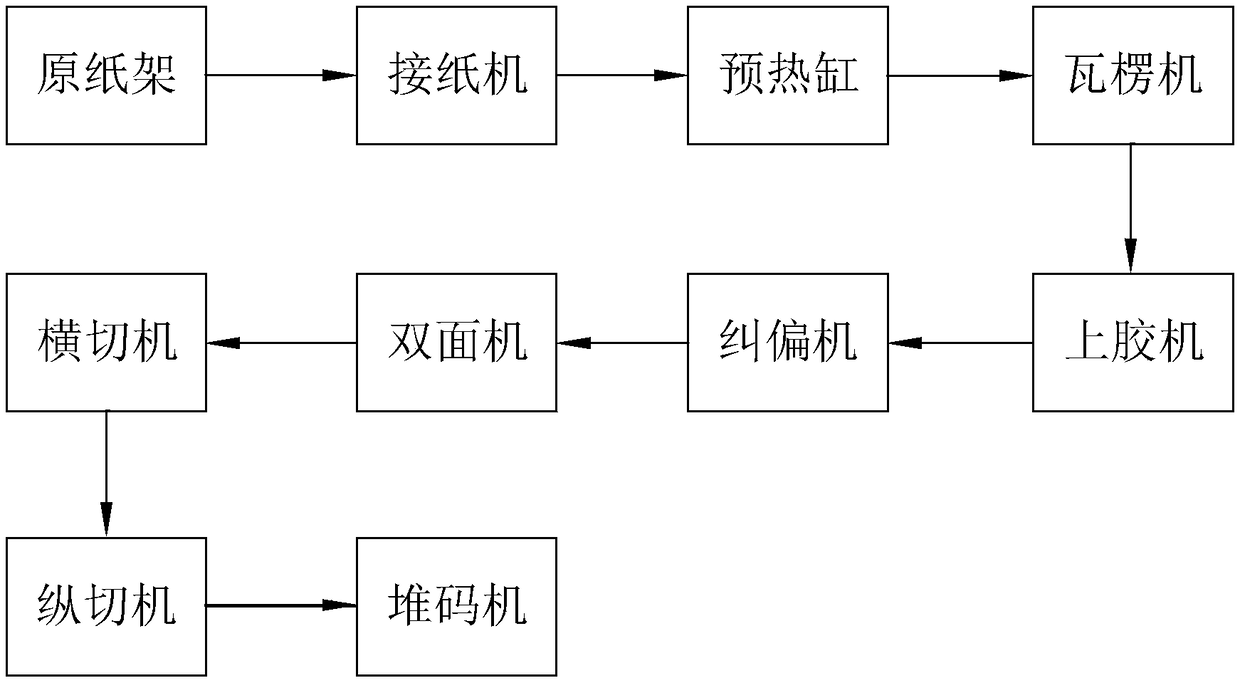

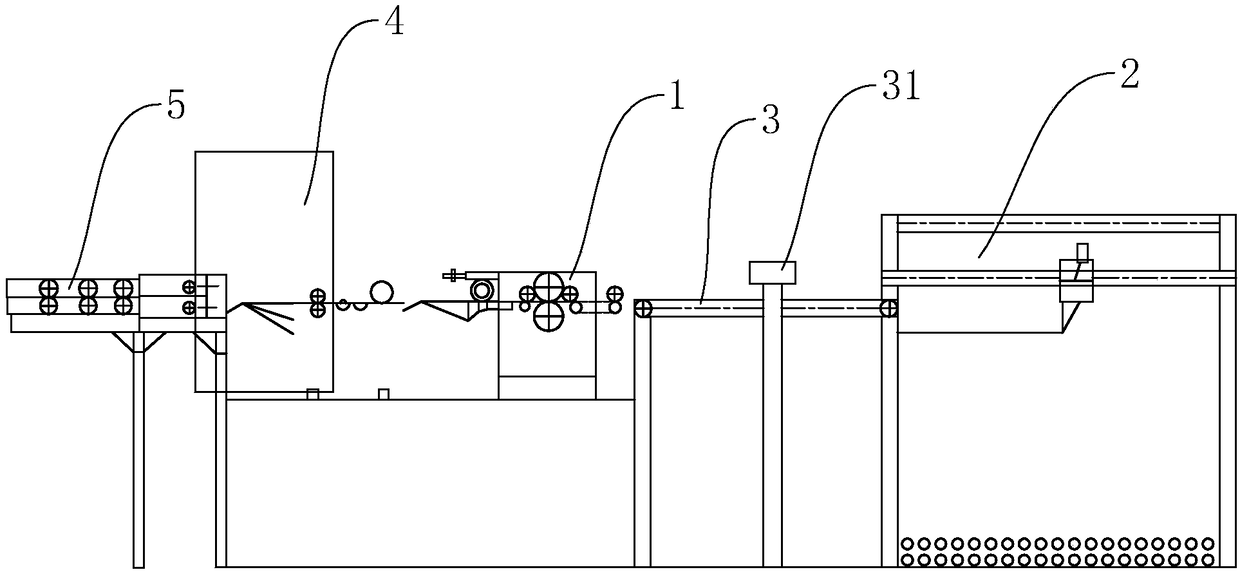

[0041] This embodiment discloses an intelligent monitoring system for warpage of corrugated cardboard, which combines figure 1 and figure 2 As shown, it includes base paper frame, paper splicer, preheating cylinder, corrugating machine, gluing machine, deviation correcting machine, double-sided machine 5, cross cutting machine 4, slitting machine 1, stacking machine 2, etc., and the roll base paper passes through An assembly line consisting of corrugated pressing, gluing, gluing, paper separation and creasing, cross-cutting, slitting into standard cardboard, and finally code output is part of the prior art and will not be described too much.

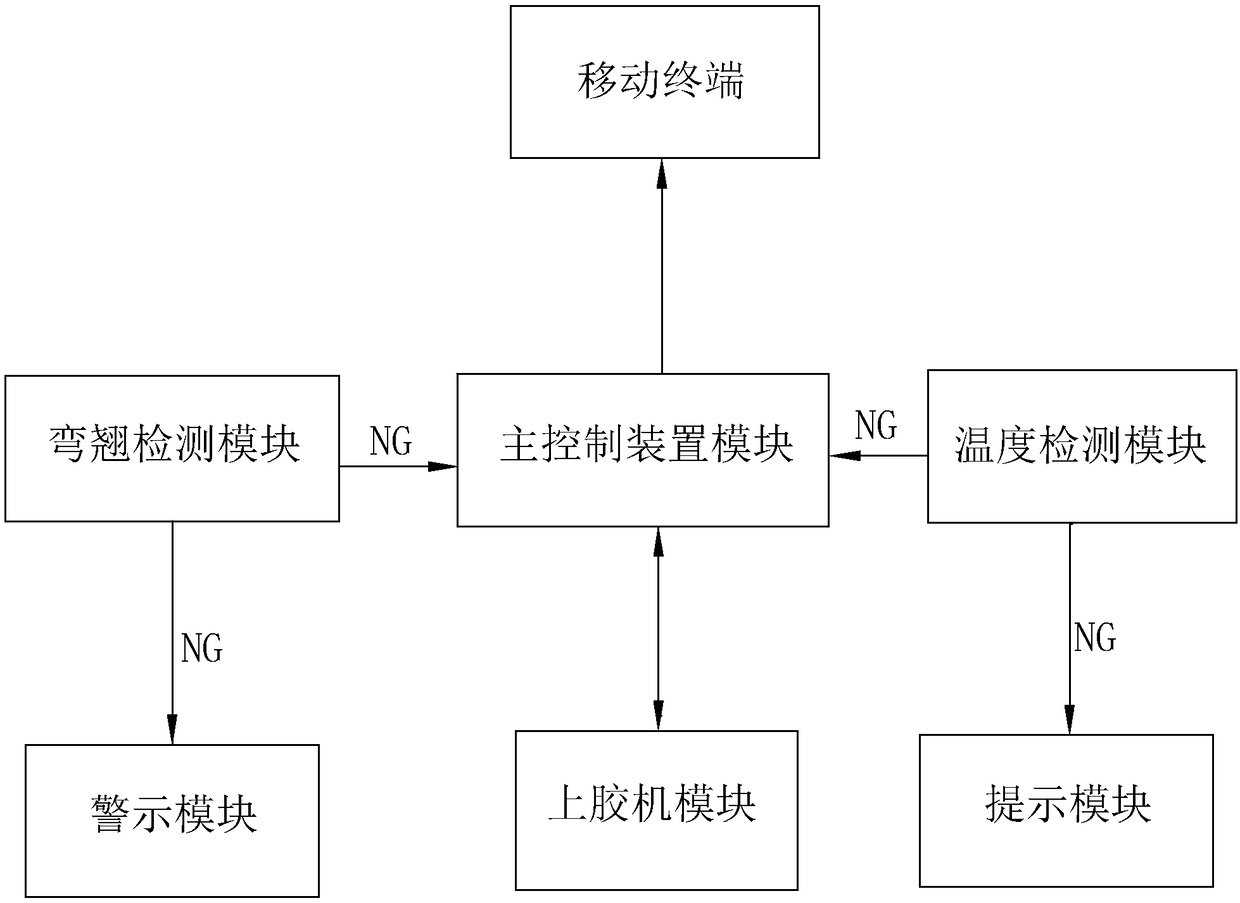

[0042] The monitoring system includes a main control module and multiple sub-control modules connected to the main control module for controlling each production equipment, and multiple sub-control modules are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com