Thermal-state replaceable pool wall structure and replacement method thereof

A replacement method and technology for pool walls, which are applied in glass furnace equipment, furnaces, glass manufacturing equipment, etc., can solve the problems of pool wall brick erosion, difficult-to-heat replacement, and tile thickness limitations, and achieve an increase in the heat dissipation area and prolongation. Service life and the effect of improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purposes, technical solutions and advantages of the embodiments of the present application clearer, the technical solutions in the disclosed embodiments will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application. Obviously, the described embodiments It is a part of the embodiments of this application, not all of them. Based on the embodiments in this application, all other embodiments obtained by those skilled in the art without making creative efforts belong to the scope of protection of this application. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

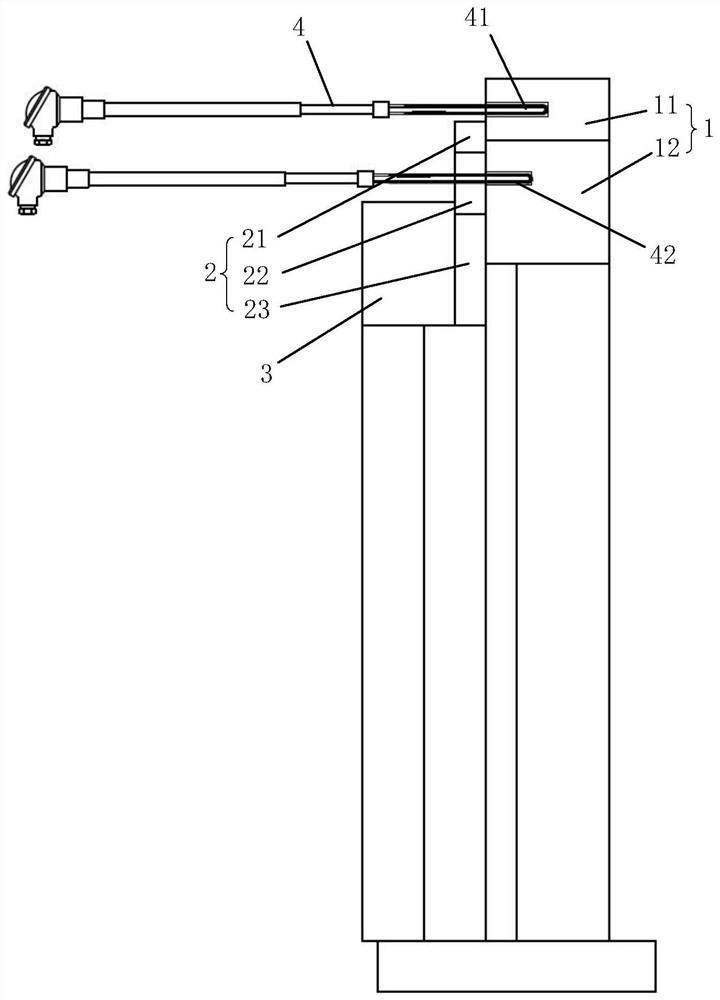

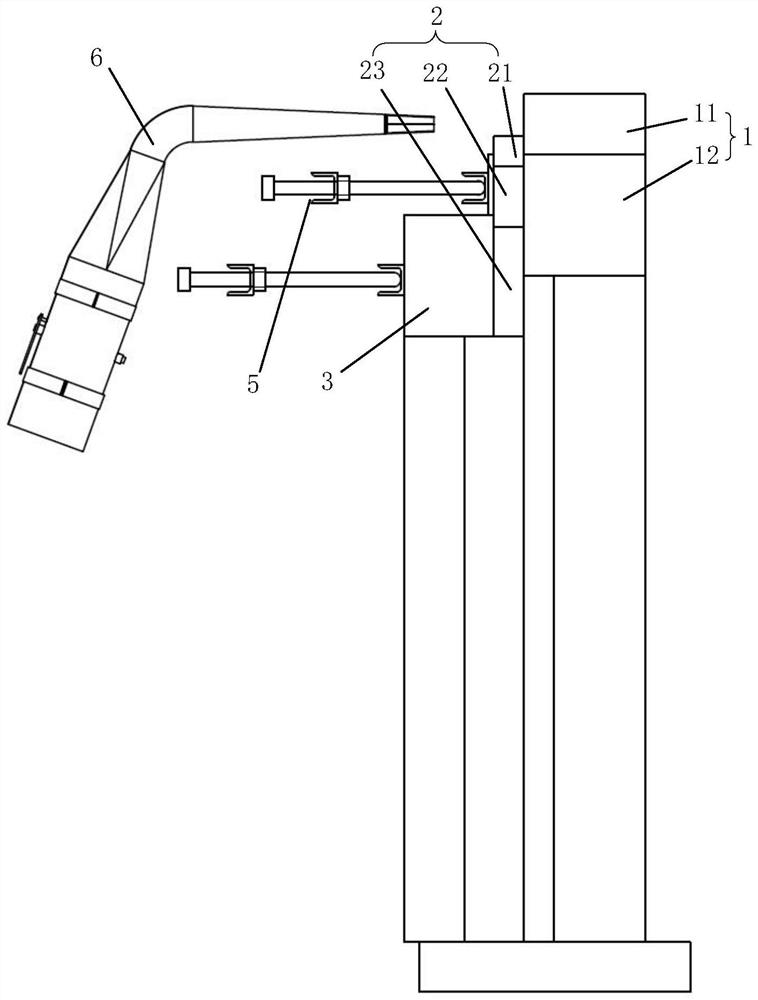

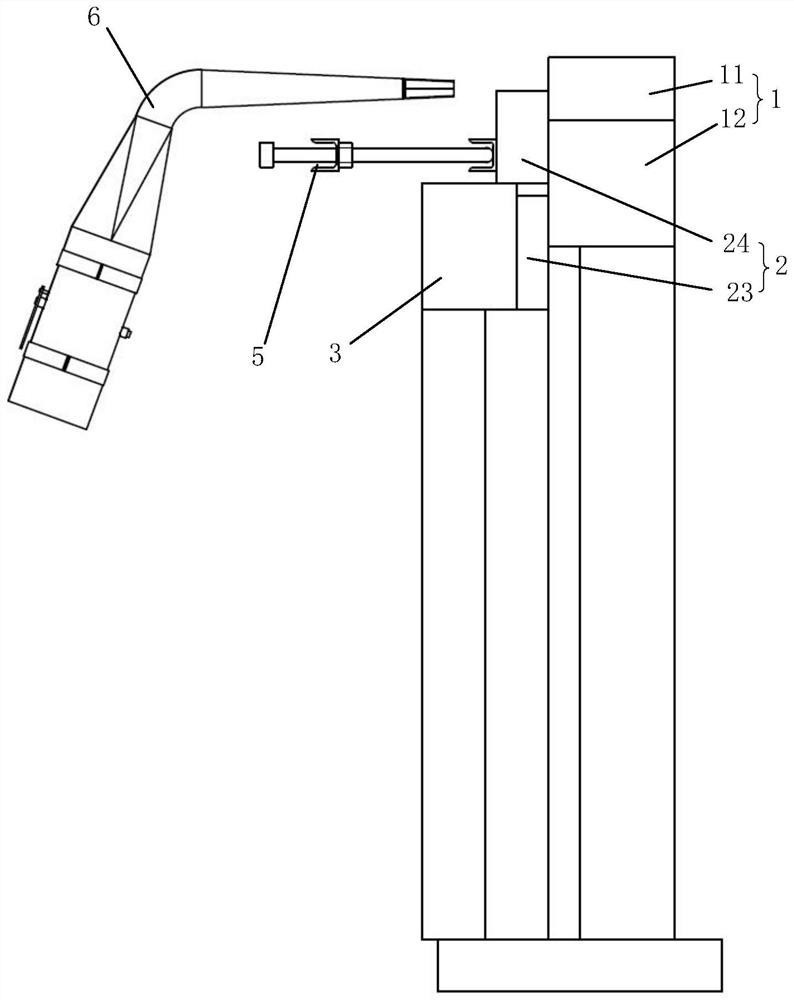

[0034] An exemplary embodiment of the present application provides a heat-replaceable pool wall structure, including a contact layer, a backing layer, and an insulating layer arranged in sequence, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com