Material suction mold of automobile air inlet valve half-gear product and material suction hole machining technology of material suction mold

A technology of air intake valve and processing technology, which is applied to home appliances, other home appliances, household components, etc., can solve the problems of unqualified products, hidden safety hazards, and difficult processing of suction holes, etc., and achieves simple structure and real-time monitoring. Cavity pressure, the effect of preventing accidental falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0020] see Figure 1 to Figure 5 , the embodiment of the present invention includes:

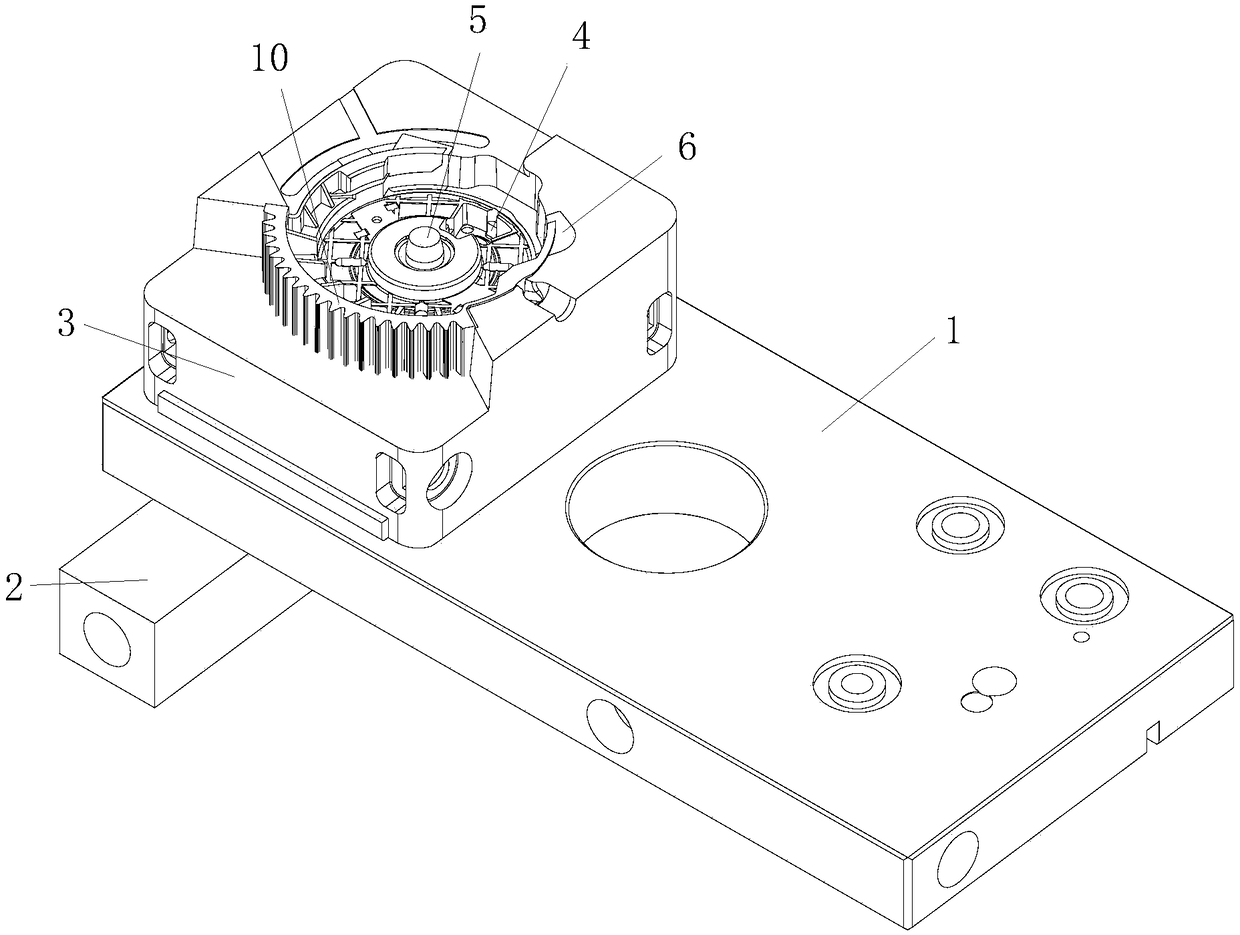

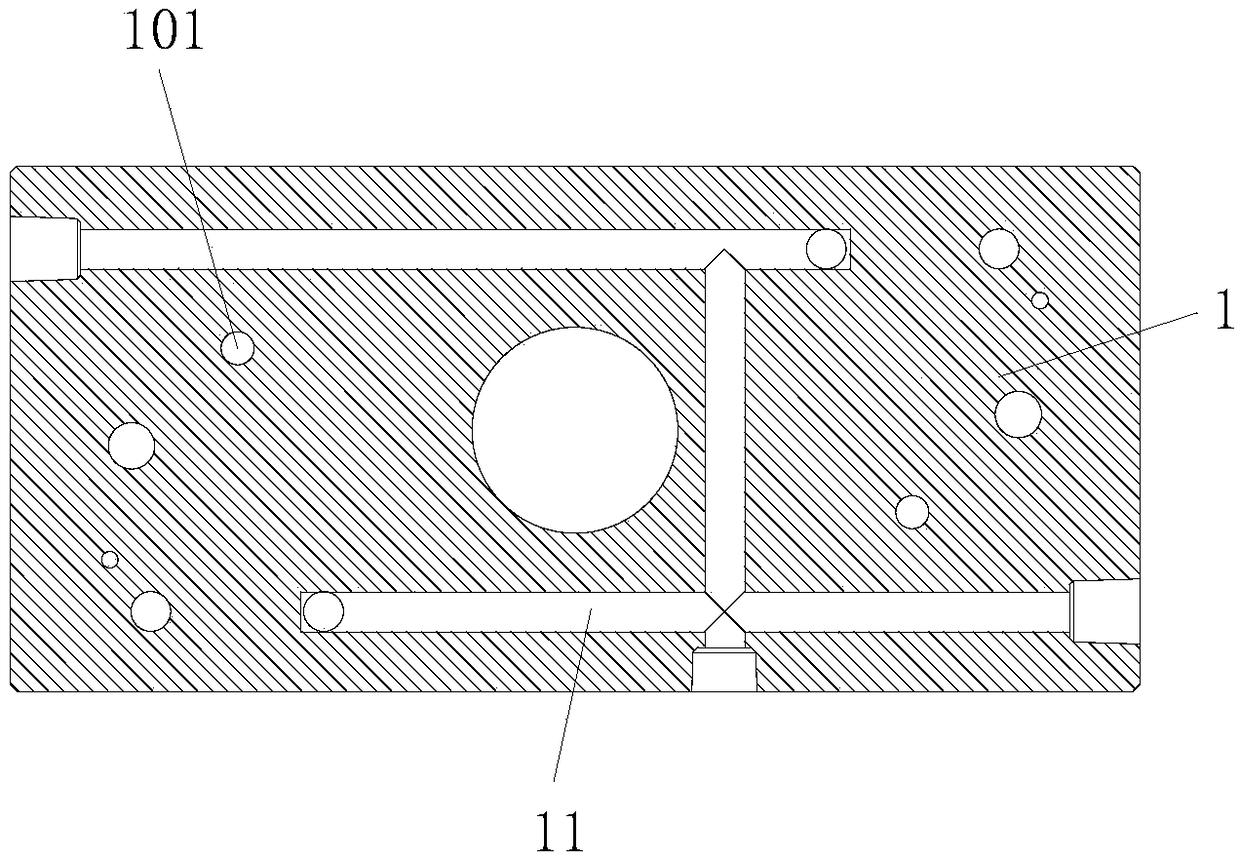

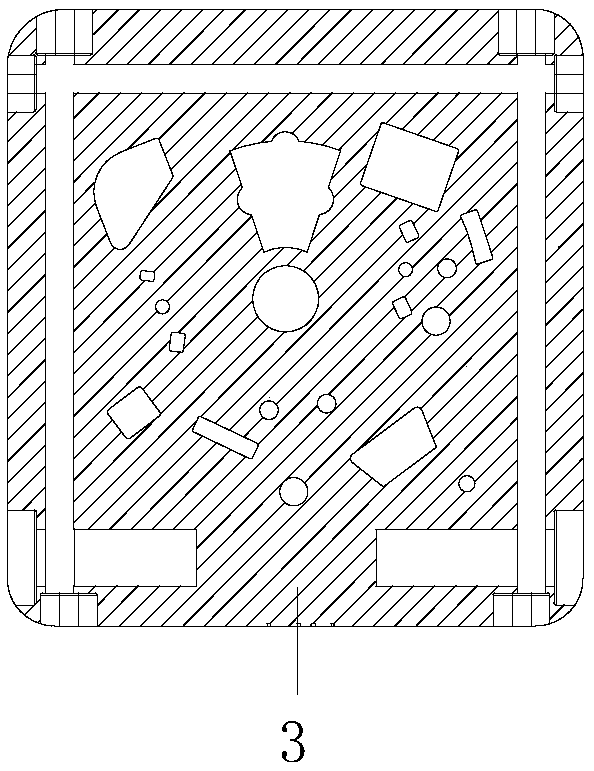

[0021] A suction mold for a semi-tooth product of an automobile air intake valve and a process for processing the suction hole thereof. The suction mold for a semi-tooth product of an automobile air intake valve includes a backing plate 1, a connecting block 2, a mold core 3, and a suction component 4 , a metal insert positioning component 5, a plastic main body positioning insert 6 and a pressure sensor 7, a connecting block 2 is provided at the lower part of the backing plate 1, a mold core 3 is installed on the backing plate 1, and a suction core 3 is inserted into ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap