New Intensive Construction Technology of Highway Prefabricated Box Girder

A construction technique and box girder technology, which is applied in manufacturing tools, ceramic molding machines, ceramic molding workshops, etc., can solve the problems of difficulty in guaranteeing the production quality of box girders, difficulties in the professionalism of workers, and low construction efficiency, so as to improve construction quality , finished product qualification rate guarantee, and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

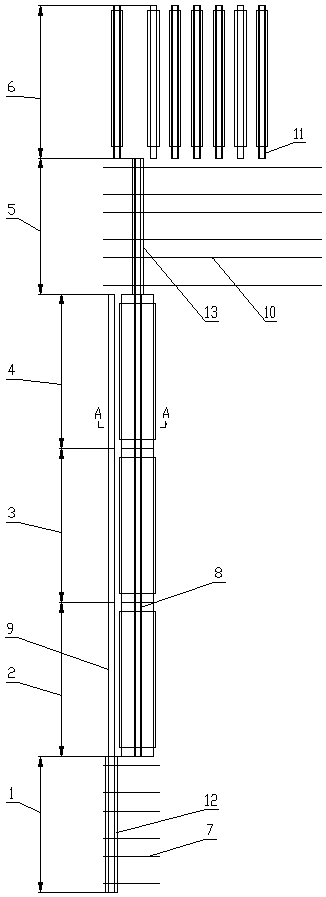

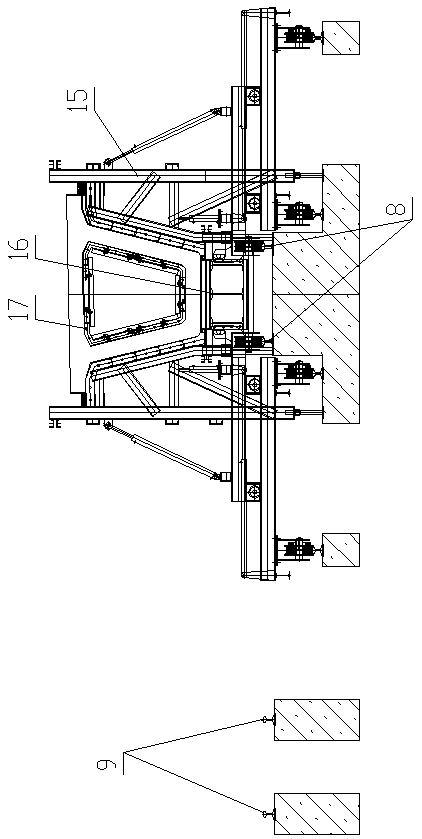

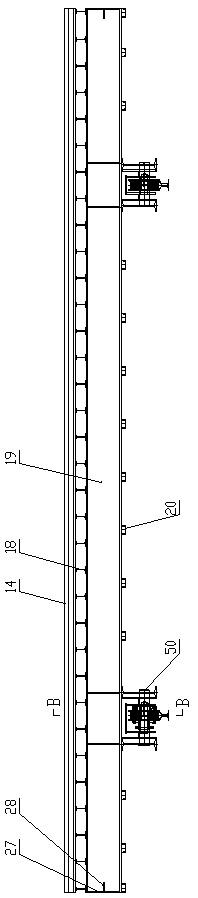

[0037] Such as Figure 1-Figure 7 As shown, the novel intensive construction technique of highway prefabricated box girder of the present invention comprises the following steps,

[0038] (1) Arranging the construction site: Set up the bottom formwork traverse area 1, the box girder steel bar binding area 2, the concrete pouring area 3, the concrete preliminary curing area 4, the initial setting concrete traverse area 5 and the Prestress tension conservation area 6;

[0039] (2) Set up tracks on the construction site: set the first traversing track 7 along the left and right horizontal direction in the bottom form traversing area 1, and set up the front and rear levels in the box girder steel bar binding area 2, concrete pouring area 3 and concrete preliminary curing area 4 Bottom mold vertical movement track 8 and bottom mold return track 9 are arranged respectively in the direction, the second traversing track 10 is set along the left and right horizontal directions in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com