Electric rust removing machine

A rust remover, electric technology, applied in grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve problems such as unfavorable production operations, high labor intensity, and high equipment noise, avoid rust splashing, and protect the construction environment. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

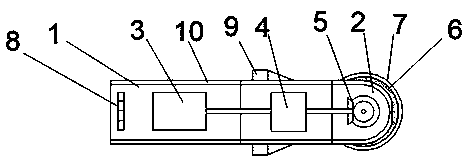

[0012] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

[0013] Such as figure 1 It shows an embodiment of an electric derusting machine of the present invention, including a body 1 and a head 2, the body 1 is fixedly connected to the head 2, and the body 1 is provided with a speed-regulating motor 3, a reducer 4 and sound-proof cotton 10. The output shaft of the speed regulating motor 3 is connected to the reducer 4, the sound insulation cotton 10 is attached to the inner wall of the machine body 1, the transmission mechanism 5 is arranged inside the machine head 2, and the derusting wheel 6 is arranged under the machine head 2, and the transmission mechanism 5 is connected Speed reducer 4 and derus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com