A logistics path planning and control method for a cold-rolled pallet transportation line

A path planning and control method technology, applied in the direction of rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of increasing the risk of equipment failure, complicated operation, and wrong material transportation, so as to optimize the actual logistics path, Improved labor efficiency, stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

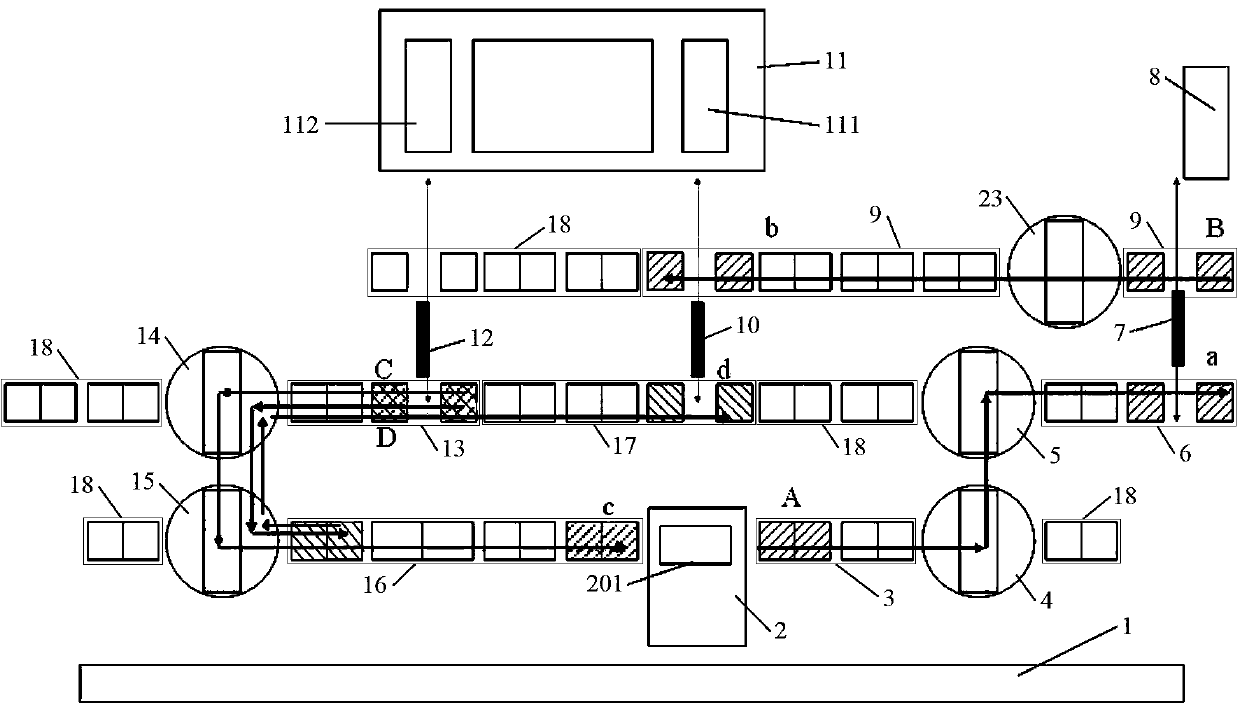

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

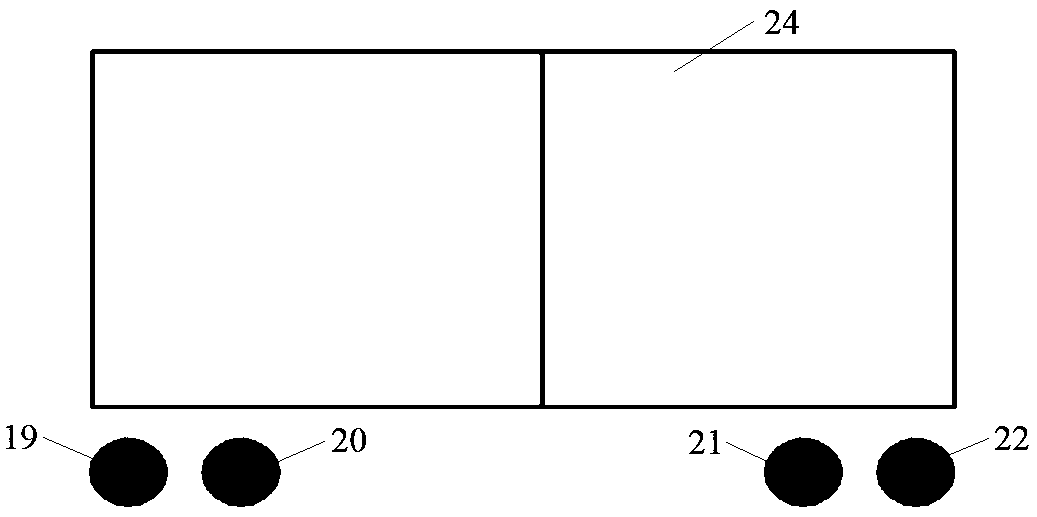

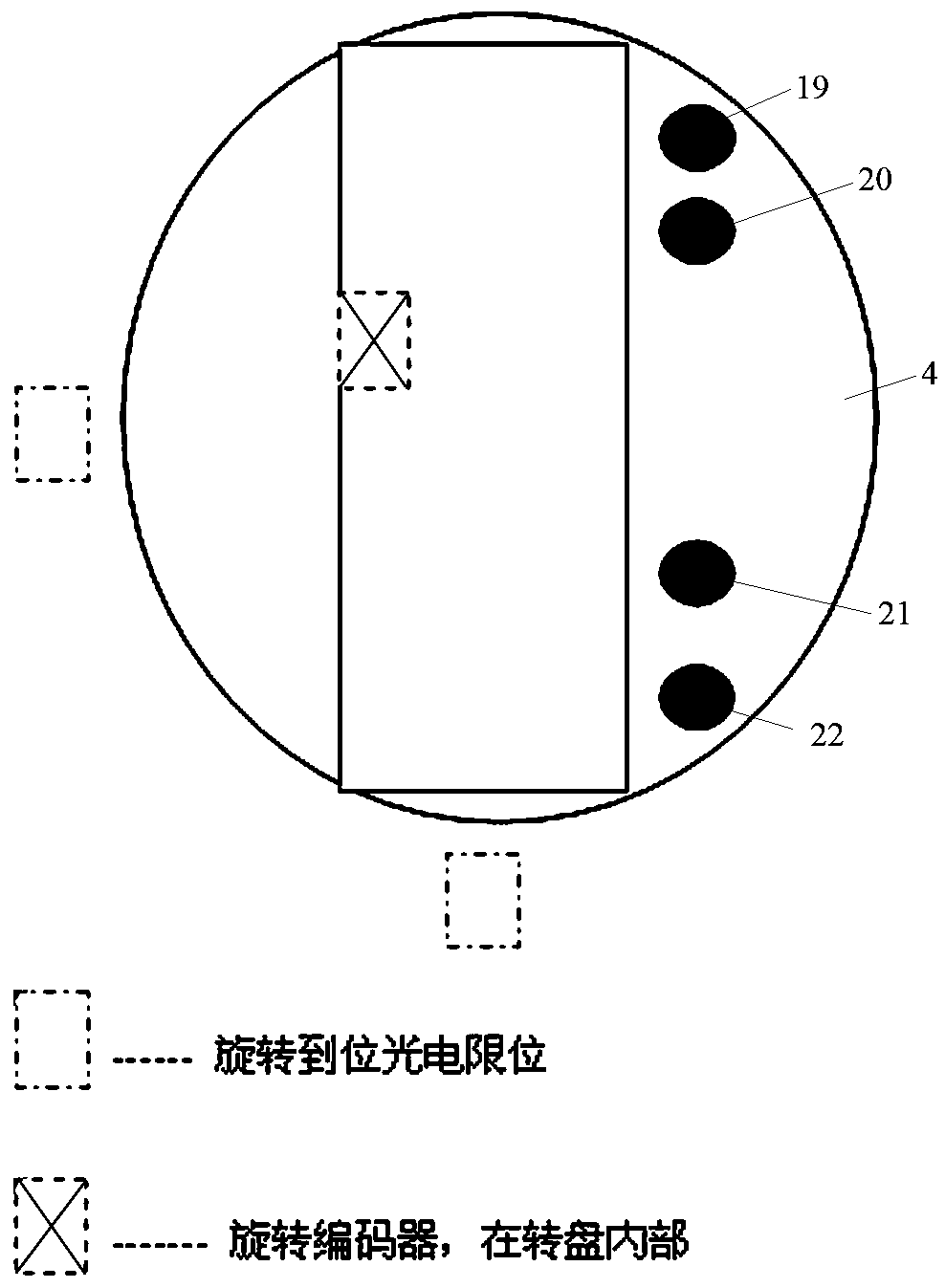

[0032] Such as figure 1 As shown, the cold-rolled pallet transport line includes an elevated warehouse 1, an elevated warehouse track 2, a first transport roller table 3, a first turntable 4, a second turntable 5, a second transport roller table 6, a preparation station transport vehicle 7, a preparation station Station 8, the third transport roller table 9, the entrance transport car 10, the cold rolling unit 11, the export transport car 12, the fourth transport roller table 13, the third turntable 14, the fourth turntable 15, the fifth transport roller table 16 and the first Six tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com