Spray coating drying device for automobile wheel hub cover production

A technology of automobile wheel hub and drying device, which is applied in the direction of surface coating liquid device, coating, pretreatment surface, etc., which can solve the problems of low drying rate, low reliability and poor practicability, and improve the drying efficiency. Drying effect, improvement of drying rate, and effect of improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

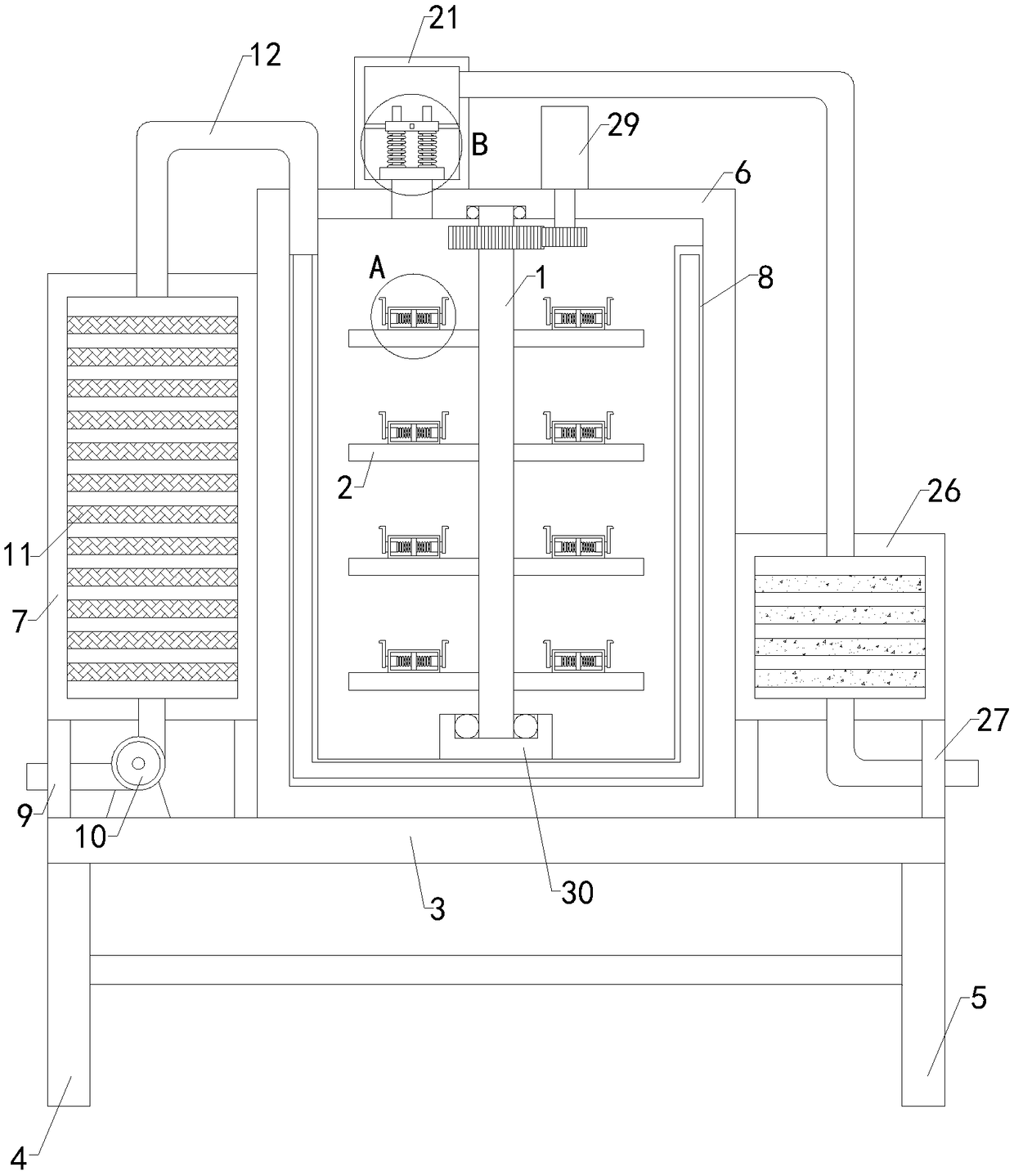

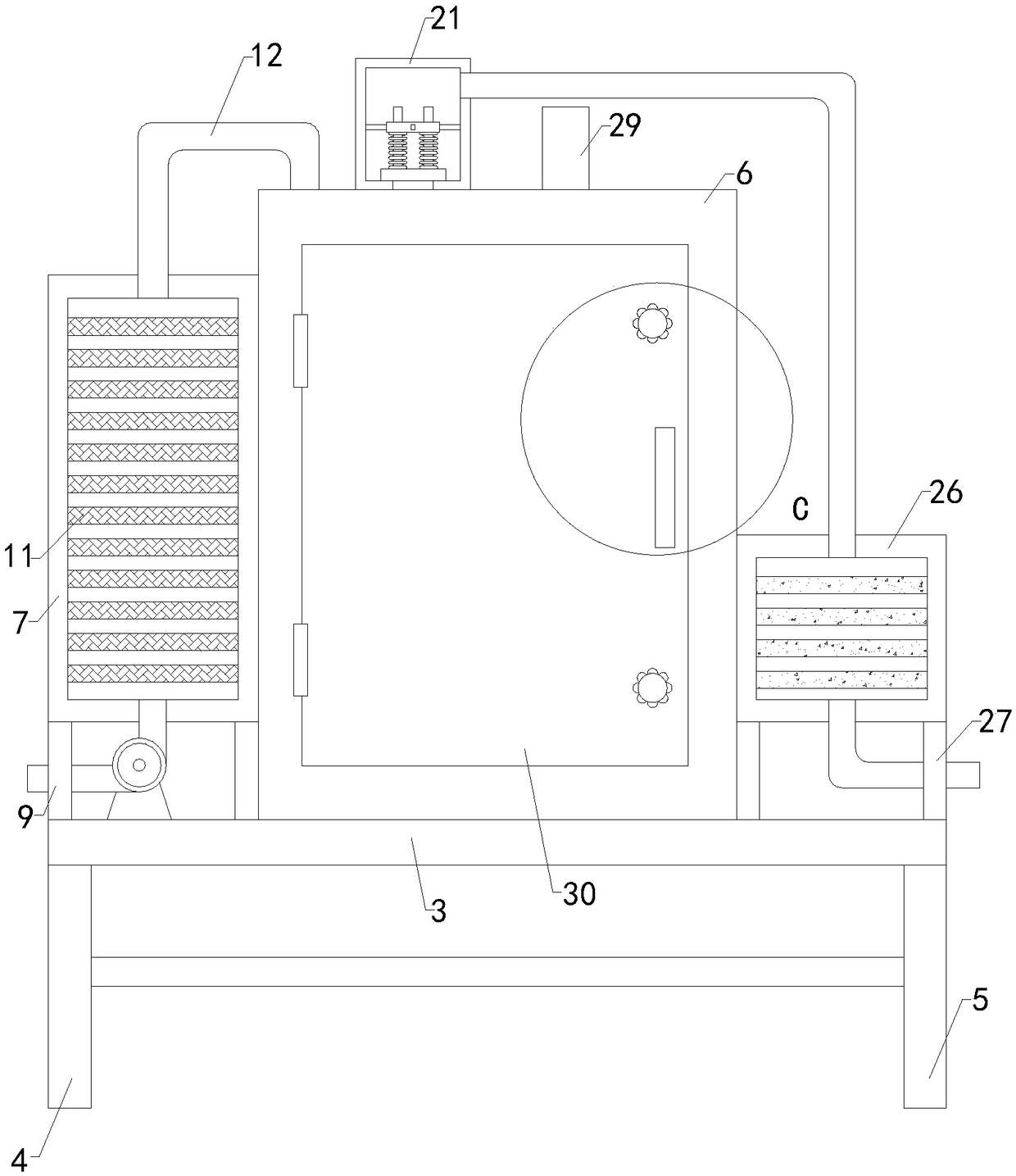

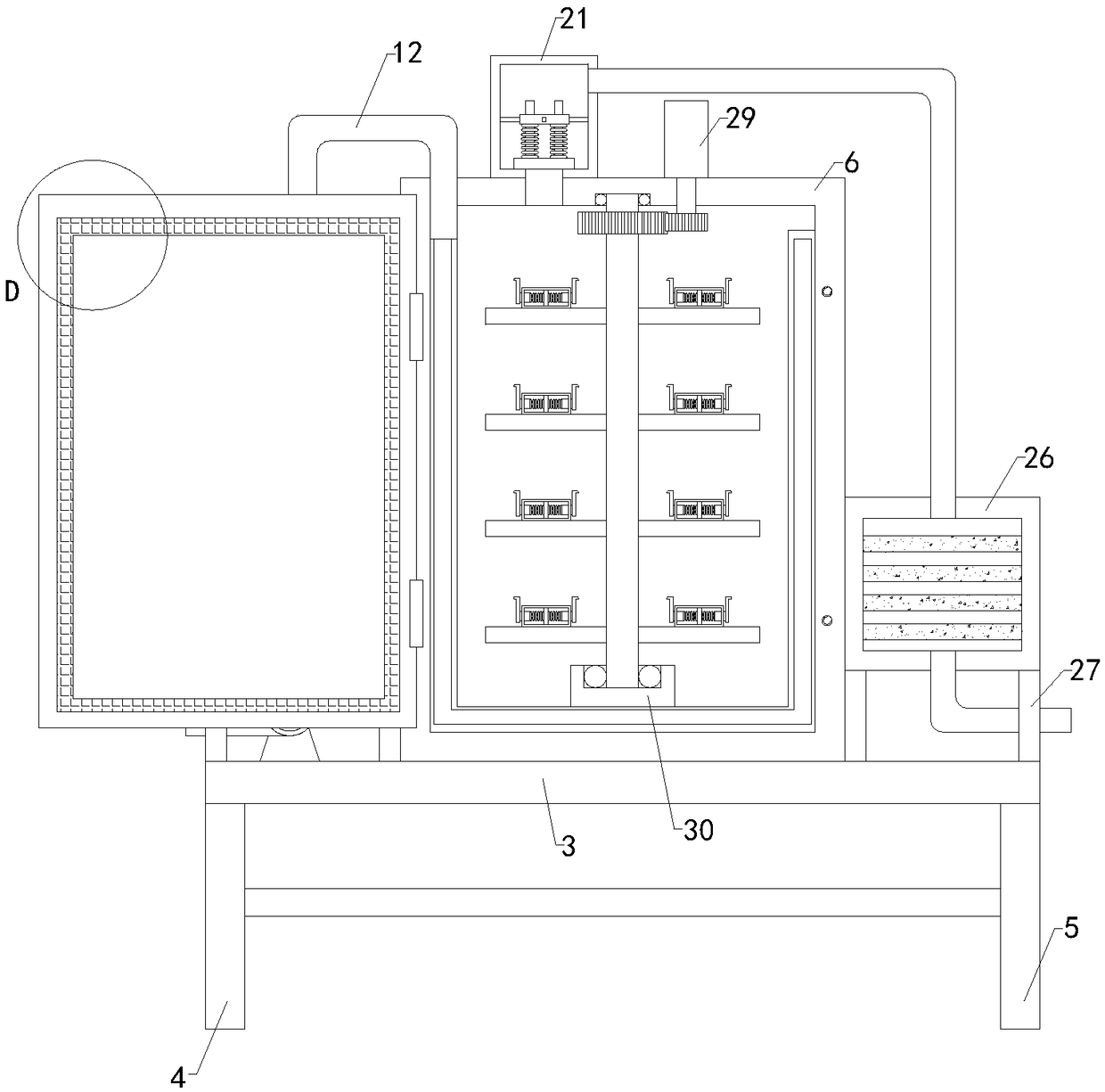

[0024] Such as Figure 1 to Figure 9 As shown, a spraying and drying device for the production of automobile hub caps of the present invention includes a support shaft 1, multiple sets of left placing plates 2, multiple sets of right placing plates, a bottom plate 3, a left supporting plate 4 and a right supporting plate 5, and the left The tops of the support plate and the right support plate are respectively connected to the left and right sides of the bottom of the base plate, the right ends of multiple sets of left placement plates are evenly distributed and longitudinally connected with the left end of the support shaft, and the left ends of multiple sets of right pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com