Liquid dung quick drying device and drying process

A rapid drying and dung water technology, applied in dehydration/drying/concentrated sludge treatment, animal husbandry wastewater treatment, etc., can solve the problems of slow, slow treatment, high water content in dung water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

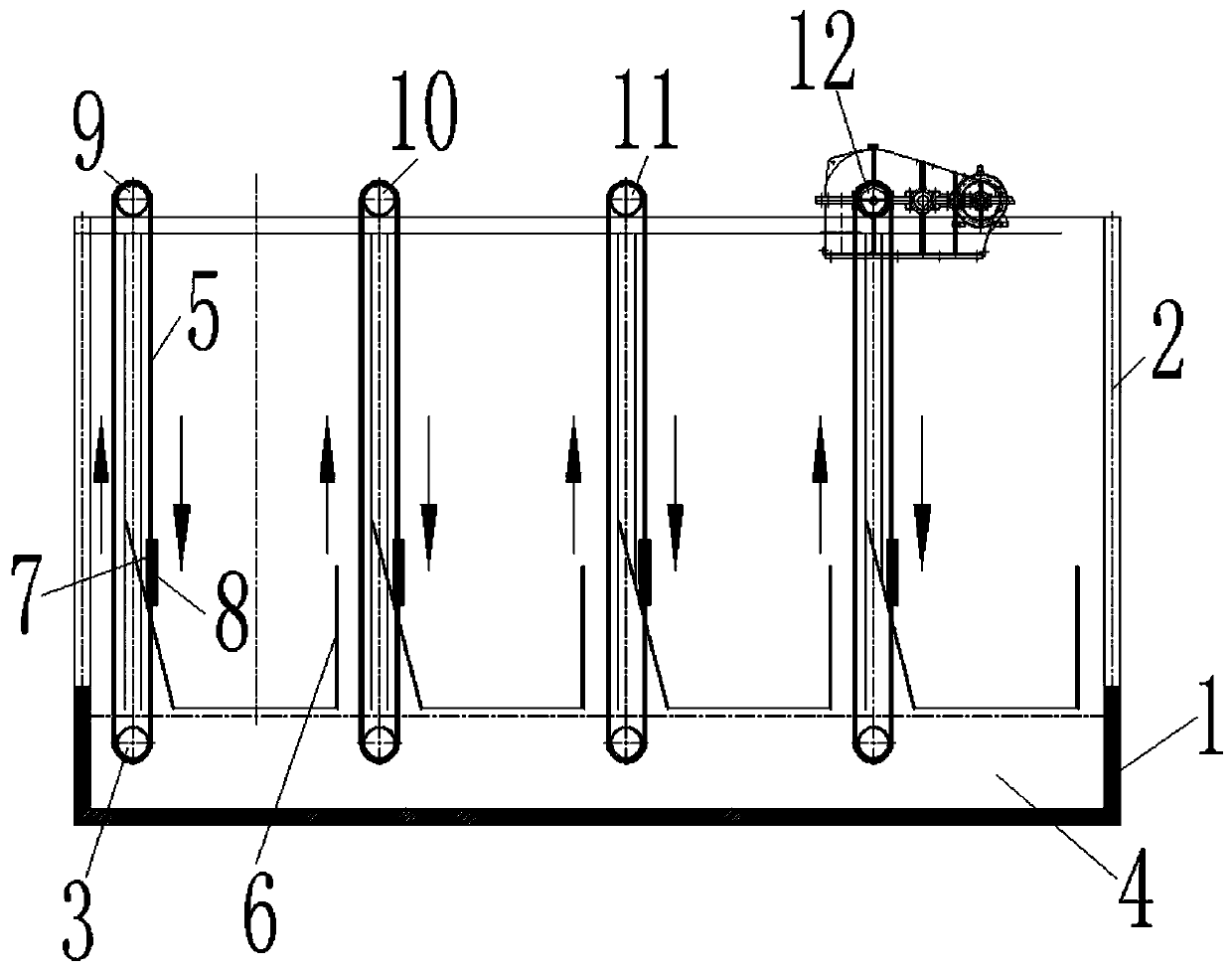

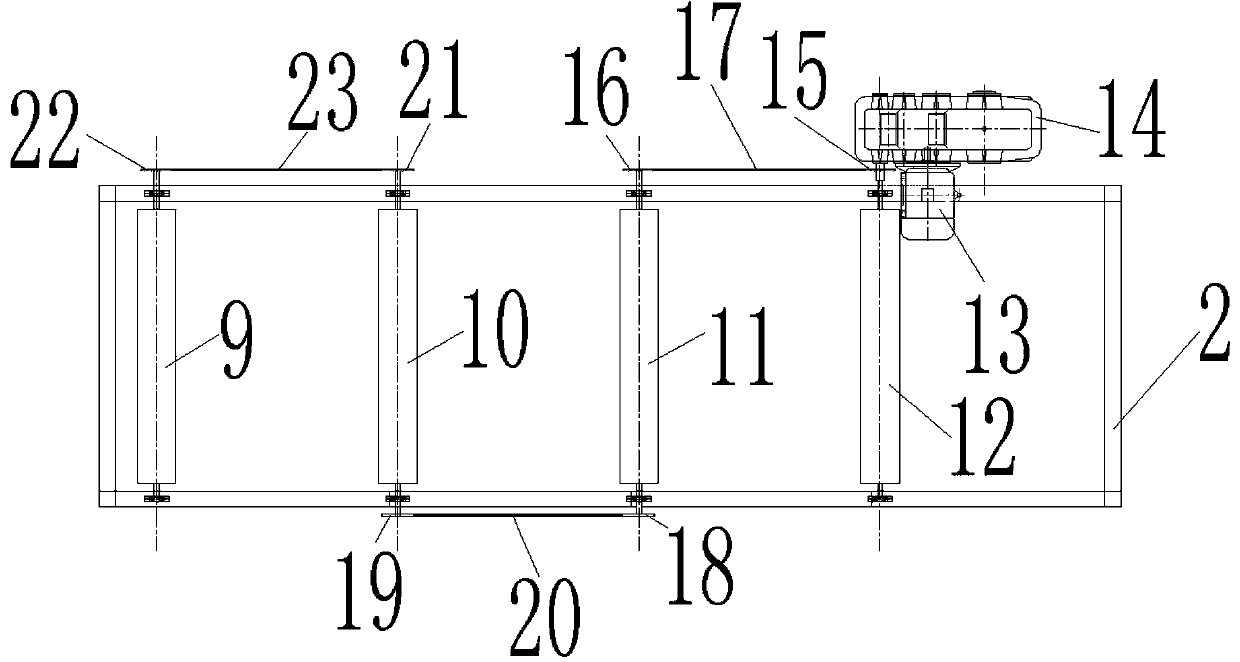

[0034] In embodiment 1, such as figure 1 and 2 As shown, a plurality of drive rollers all rotate in the same direction, taking clockwise rotation as an example, between the front and rear inner side walls of the shed body 2, a collection tank 6 with an upper end opening is fixed at the position on the right side of the absorption belt of the drying unit, and the collection tank 6. The right end is at the left side of the adjacent absorption zone on the right. The left side wall of the collection tank 6 is inclined and recorded as the collection side wall. The upper end of the collection side wall is at the corresponding position in the annular space surrounded by the corresponding water absorption zone 5. The side wall is provided with a water-absorbing belt inlet for the corresponding water-absorbing belt 5 to pass through, and the inner side wall of the collecting tank 6 is fixed with a left scraper 7 inclined to the left and a right and a right downwards to the right at a p...

Embodiment 2

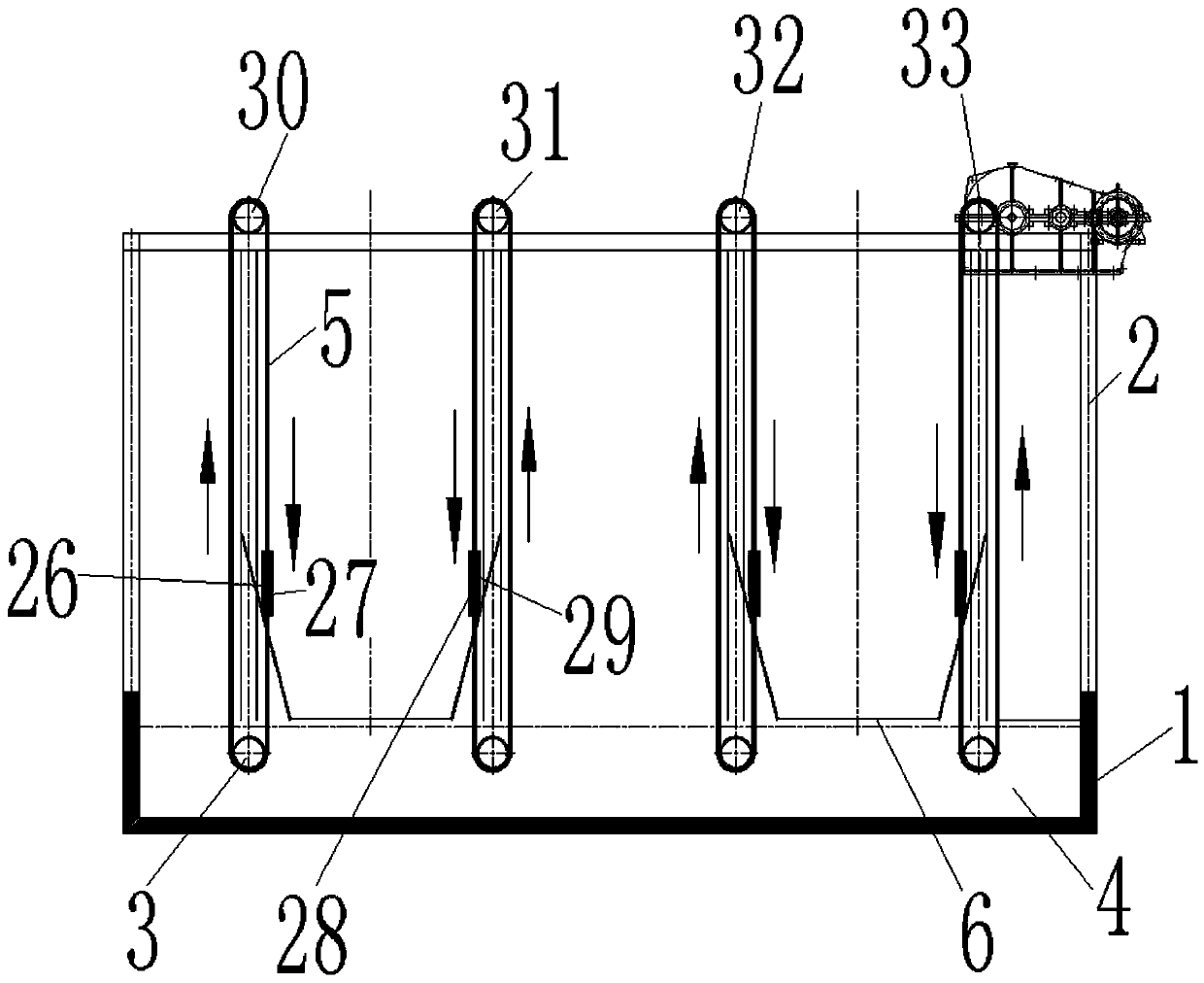

[0036] In embodiment 2, such as image 3 , 4, 5, 6 and 7, the adjacent drive rollers rotate in reverse, and the number of drive rollers can be odd or even, taking the number of drive rollers as an example, the adjacent drive rollers rotate in reverse, and the leftmost The side driving roller rotates clockwise, and a collecting tank 6 with an upper end opening is fixed at the corresponding position between the front and rear inner side walls of the shed body 2 between the clockwise rotating driving roller and the right adjacent counterclockwise rotating driving roller. The upper end of the left side wall of the groove 6 is at the corresponding position in the annular space surrounded by the water-absorbing belt 5 corresponding to the corresponding clockwise rotating driving roller on the left side, and the upper end of the right side wall of the collecting tank 6 is at the corresponding position of the water-absorbing belt corresponding to the counterclockwise rotating driving ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com