Drought-enduring seed coating agent of oilseed rape

A coating agent and seed technology, applied in the field of bioengineering, can solve the problems of ineffectiveness in improving the drought tolerance of plant seeds, and the types of agents are few, and achieve the effects of remarkable drought-resistant seedling emergence, promoting seed germination, and improving osmotic adjustment ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

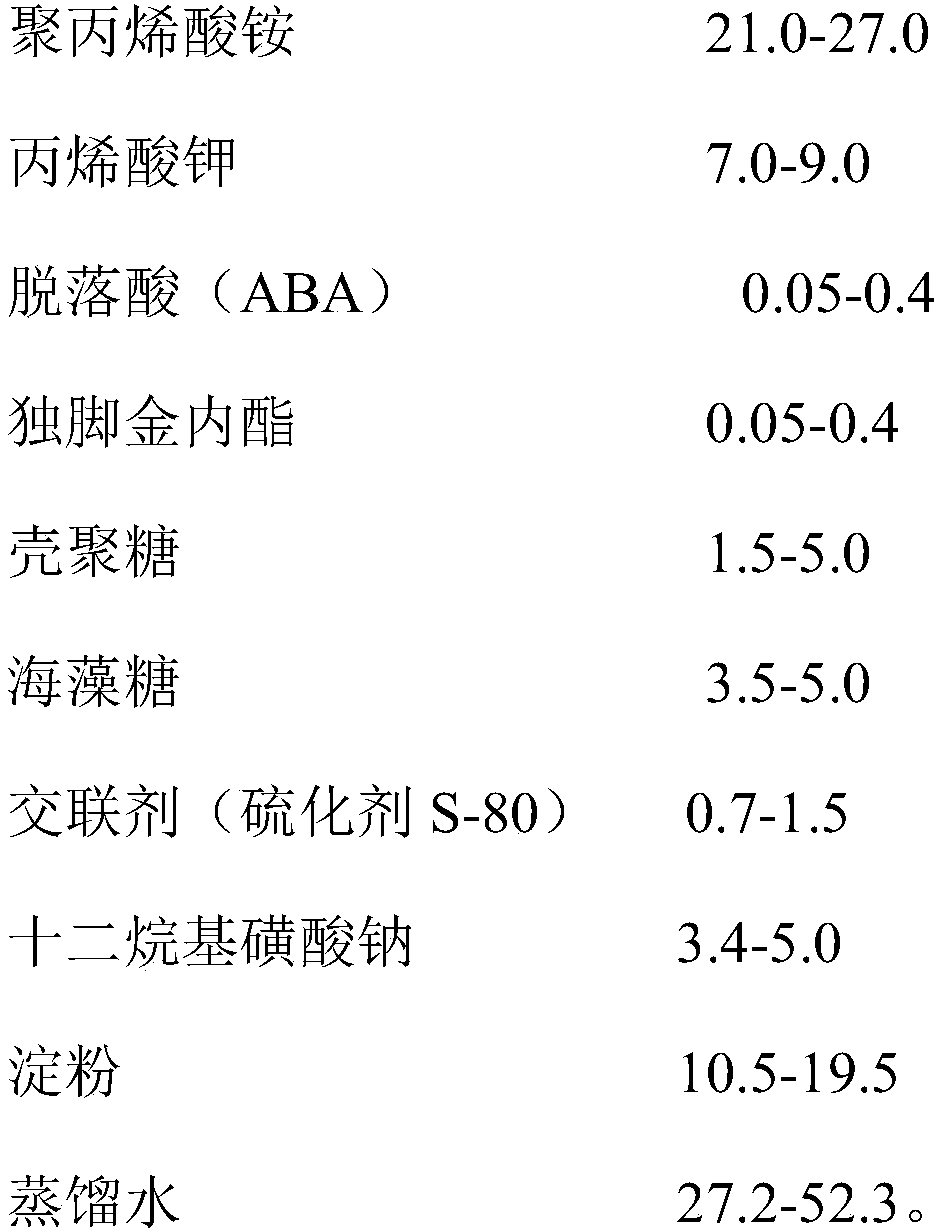

[0036] A drought-tolerant seed coating agent for rapeseed, made of the mass fractions of the following raw materials: 22.5 grams of ammonium polyacrylate, 7.5 grams of potassium acrylate, 0.1 grams of abscisic acid (ABA), 0.1 grams of strigolactone, and 2.5 grams of chitosan gram, 3.5 grams of trehalose, 0.8 grams of crosslinking agent (curing agent S-80), 3.5 grams of sodium lauryl acid, 12.0 grams of starch, and the remainder being 47.5 grams of distilled water.

[0037] The preparation of the present invention is prepared by mixing the above-mentioned raw material components in proportion. Get 500ml of the preparation of the present invention for every 10kg of rapeseed, and dress the seeds before sowing the rapeseed. Using Zhongyouza 12, a rapeseed variety bred by the Research Institute of Oil Crops, Chinese Academy of Agricultural Sciences, as the test variety, the results of the comparison between the effect after seed dressing and the untreated control are as follows:

...

Embodiment 2

[0042]A drought-tolerant seed coating agent for rapeseed, made from the mass fraction of the following raw materials: 26.4 grams of ammonium polyacrylate, 8.8 grams of potassium acrylate, 0.3 grams of abscisic acid (ABA), 0.3 grams of strigolactone, and 3.5 grams of chitosan gram, 4.5 grams of trehalose, 1.5 grams of cross-linking agent (curing agent S-80), 4.5 grams of sodium laurylate, 19.0 grams of starch, and the remainder being 31.2 grams of distilled water.

[0043] The preparation steps and application method are the same as in Example 1, that is, the above-mentioned raw material components are mixed in proportion and then stirred evenly. Get 500ml of the preparation of the present invention for seed dressing per 10kg of rapeseed before rapeseed sowing. Taking the rapeseed cultivar Sunshine 2009 bred by the Oil Crops Research Institute of the Chinese Academy of Agricultural Sciences as the test variety, the results of the comparison between the effect after seed dressin...

Embodiment 3

[0046] A drought-tolerant seed coating agent for rapeseed, made of the mass fractions of the following raw materials: 24.6 grams of ammonium polyacrylate, 8.2 grams of potassium acrylate, 0.2 grams of abscisic acid (ABA), 0.2 grams of strigolactone, and 3.0 grams of chitosan gram, 4.0 grams of trehalose, 1.1 grams of crosslinking agent (curing agent S-80), 4.0 grams of sodium lauryl acid, 15.5 grams of starch, and the remainder being 39.7 grams of distilled water.

[0047] The preparation steps and application method are the same as in Example 1, that is, the above-mentioned raw material components are mixed in proportion and then stirred evenly. Get 500ml of the preparation of the present invention for seed dressing per 10kg of rapeseed before rapeseed sowing. Taking the rapeseed variety Zhongshuang 11 bred by the Research Institute of Oil Crops of the Chinese Academy of Agricultural Sciences as the test variety, the results of the comparison between the effect after seed dre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com