Novel stainless steel flowerpot

A technology of stainless steel and flower pots, which is applied in the field of landscaping and decoration, can solve the problems of fragile, difficult to recycle, and low impact resistance, and achieve the effects of not easy to break, easy to recycle, and solve the impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

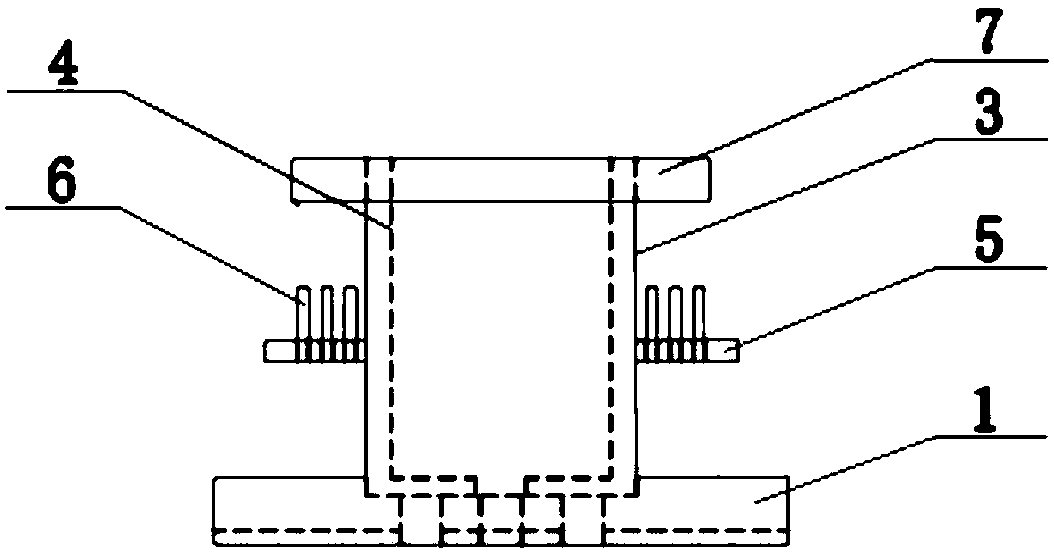

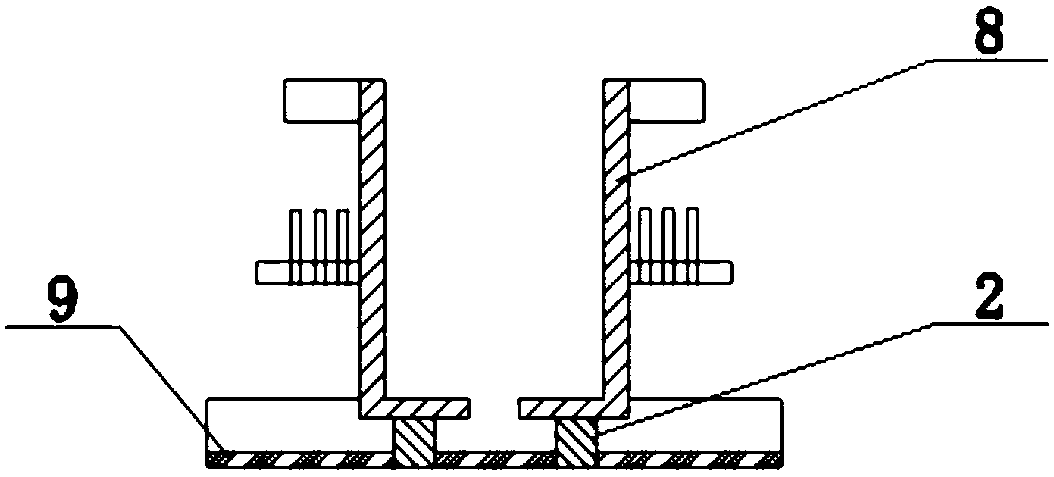

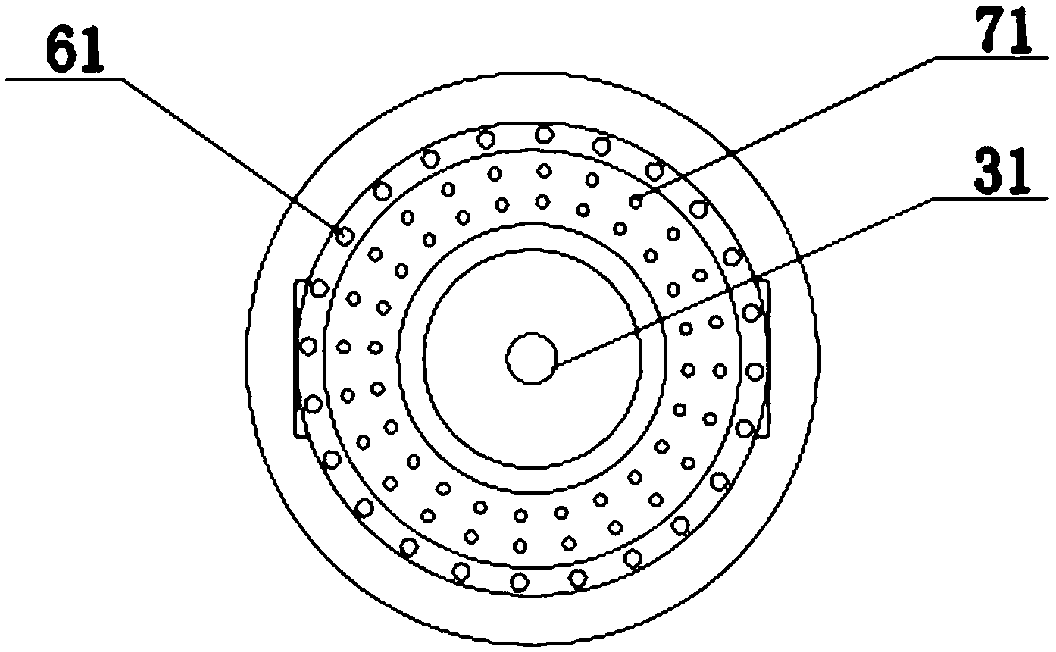

[0017] see Figure 1-Figure 3 As shown, the technical solution adopted in this specific embodiment is: it includes a bottom basin 1, a connecting column 2, a main body 3, a net 4, a side platform 5, a side platform 6, a top basin 7, an absorption layer 8, and a bottom plate 9, A bottom plate 9 is arranged above the bottom basin 1, and the bottom basin 1 is welded and fixed with the main body 3 through the connecting column 2, and the connecting column 2 passes through the bottom plate 9, and the inside of the main body 3 is provided with a partition net 4, between the main body 3 and the partition net 4 An absorption layer 8 is provided, side platforms 5 are welded in the middle of both sides of the main body 3, and a plurality of side platforms 6 are evenly arranged on the side platforms 5, and a top basin 7 is welded on the periphery of the upper end of the main body 3, a bottom basin 1, a connecting column 2, The main body 3, the side platform 5 and the top basin 7 are all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com