Suction self-propelled cotton harvester

A cotton harvesting and self-propelled technology, which is applied to harvesters, pickers, agricultural machinery and implements, etc., can solve problems such as blockage of conveying channels and affect work, and achieve the effect of improving passability and reducing the quality of seed cotton

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

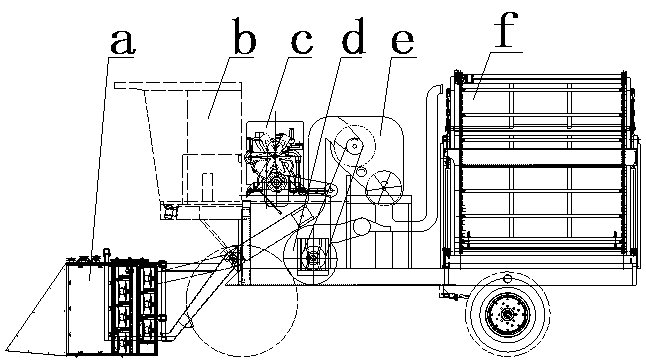

[0028] The air suction self-propelled cotton harvester of the present embodiment, as figure 1 As shown, it includes: picking platform a, conveying device e, cotton box f and self-propelled chassis; where driver's seat b, engine c and transmission assembly are arranged on the self-propelled chassis; meanwhile, conveying device e is arranged in the middle of the bottom, cotton box f Arranged at the tail of the chassis; the picking table a is installed at the front end of the self-propelled chassis; the picking table a is connected to the cotton box f through the conveying device e.

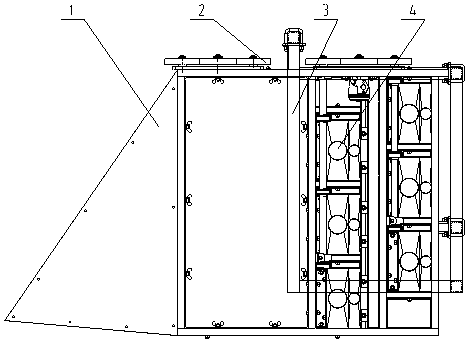

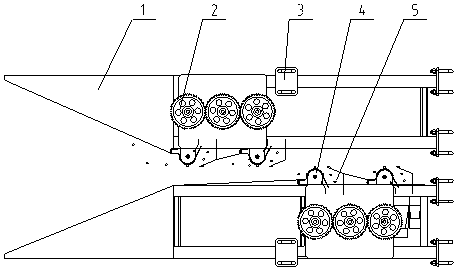

[0029] Among them, the picking station a is as figure 2 and image 3 As shown, it includes: a main frame 3, a grain divider 1, a transmission system 2 and a picking device 4; the front end of the main frame 3 has two installation arms extending forward, and the front ends of the two installation arms are equipped with a grain divider 1 , there is a gap between the mounting arms; in the gap, sever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com