Gravity type propeller noise measuring device

A propeller and gravity-type technology, applied in the field of propeller noise detection devices, can solve problems such as increasing the impact of environmental noise and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following examples describe the present invention in more detail.

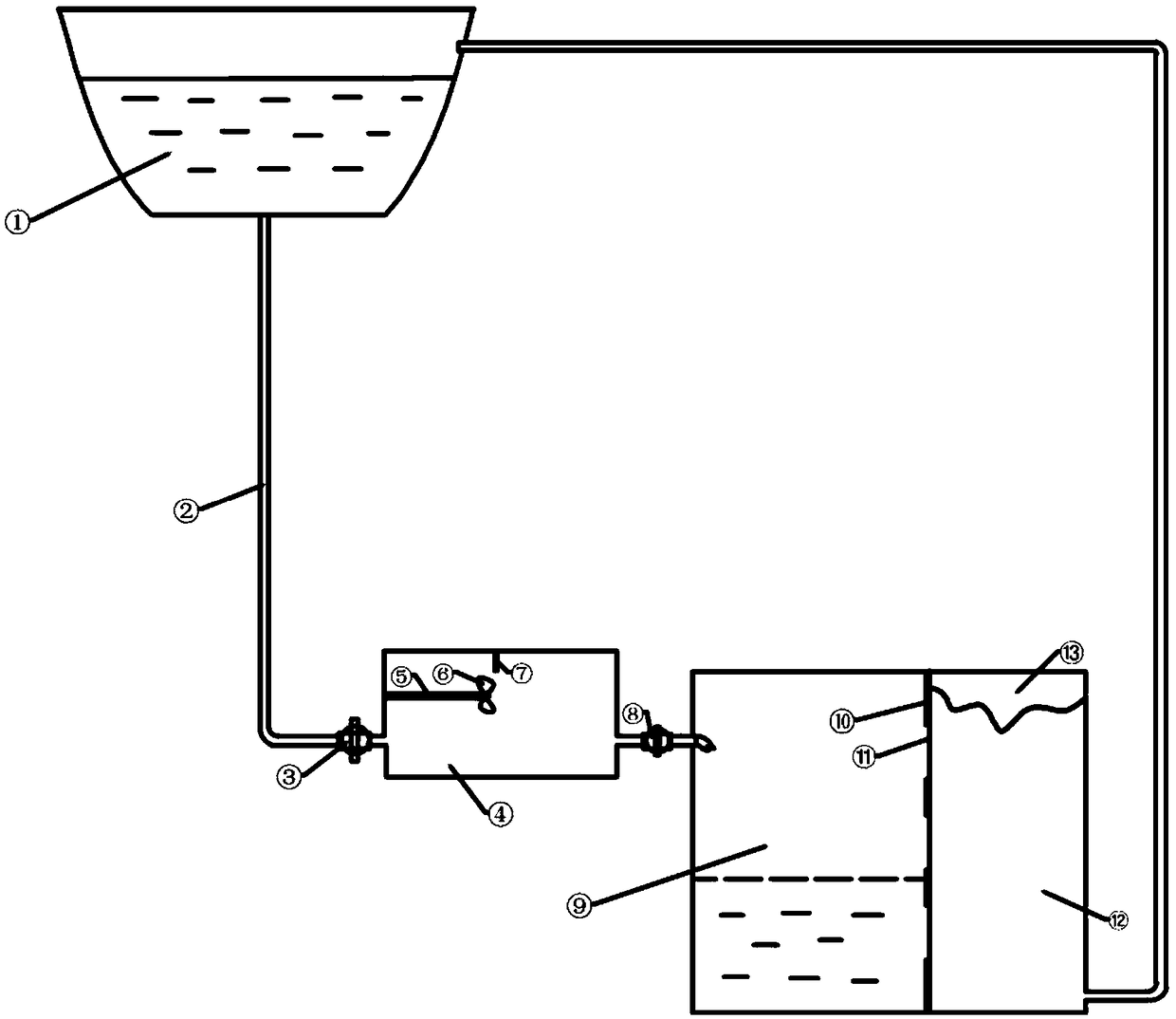

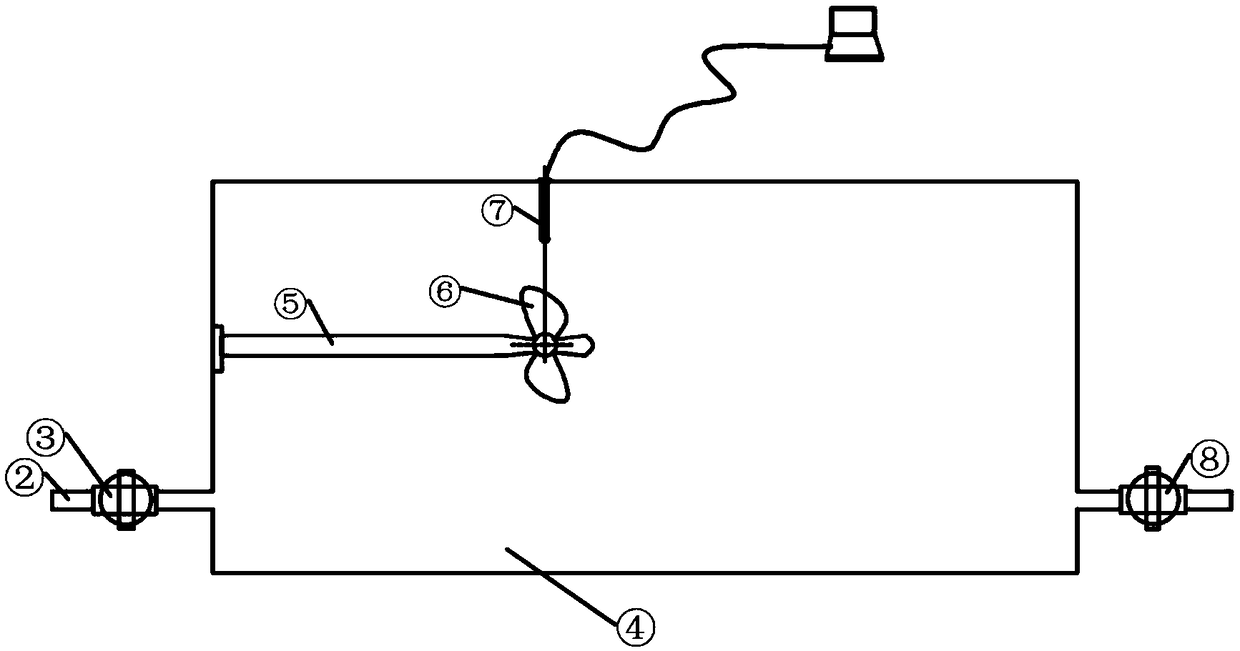

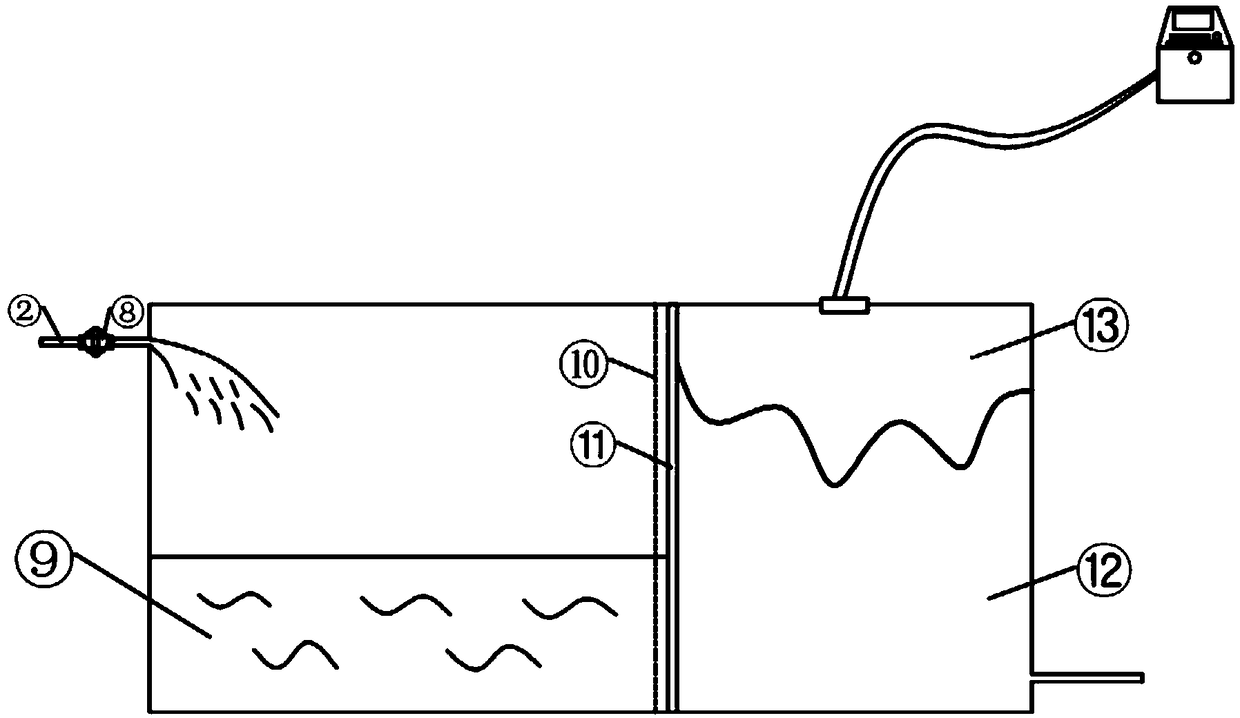

[0019] combine Figure 1 to Figure 3 , the gravity propeller noise measuring device of the present invention comprises a rainwater collector 1, a water pipe 2, a first valve 3, an experimental water tank 4, a long-axis dynamometer 5, a propeller 6, a hydrophone 7, a second valve 8, and a reservoir The open part 9, the filter screen 10, the partition 11, the closed part 12 of the reservoir, and the air bag 13. The rainwater collector 1 is a super-large cistern set at a high position, connected to the experimental water tank 4 through a water pipe; the water pipe is equipped with a first valve 3 and a second valve 8, which control the size of the water flow and the progress of the experiment respectively. A long-axis dynamometer 5 is installed in the experimental water tank 4, and a propeller 6 is installed on the long-axis dynamometer 5. The hydrophone 7 is used to collect the noise of the rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com