Rear H-shaped steel cantilever scaffold and construction method thereof

A technology of cantilevered scaffolding and construction method, applied in the field of scaffolding, can solve the problems of damage to existing concrete floors, low strength of floor concrete, affecting the construction of cantilevered scaffolding, etc., to achieve the safety of cantilevered scaffolding, a wide range of use, and reduced restrictions desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

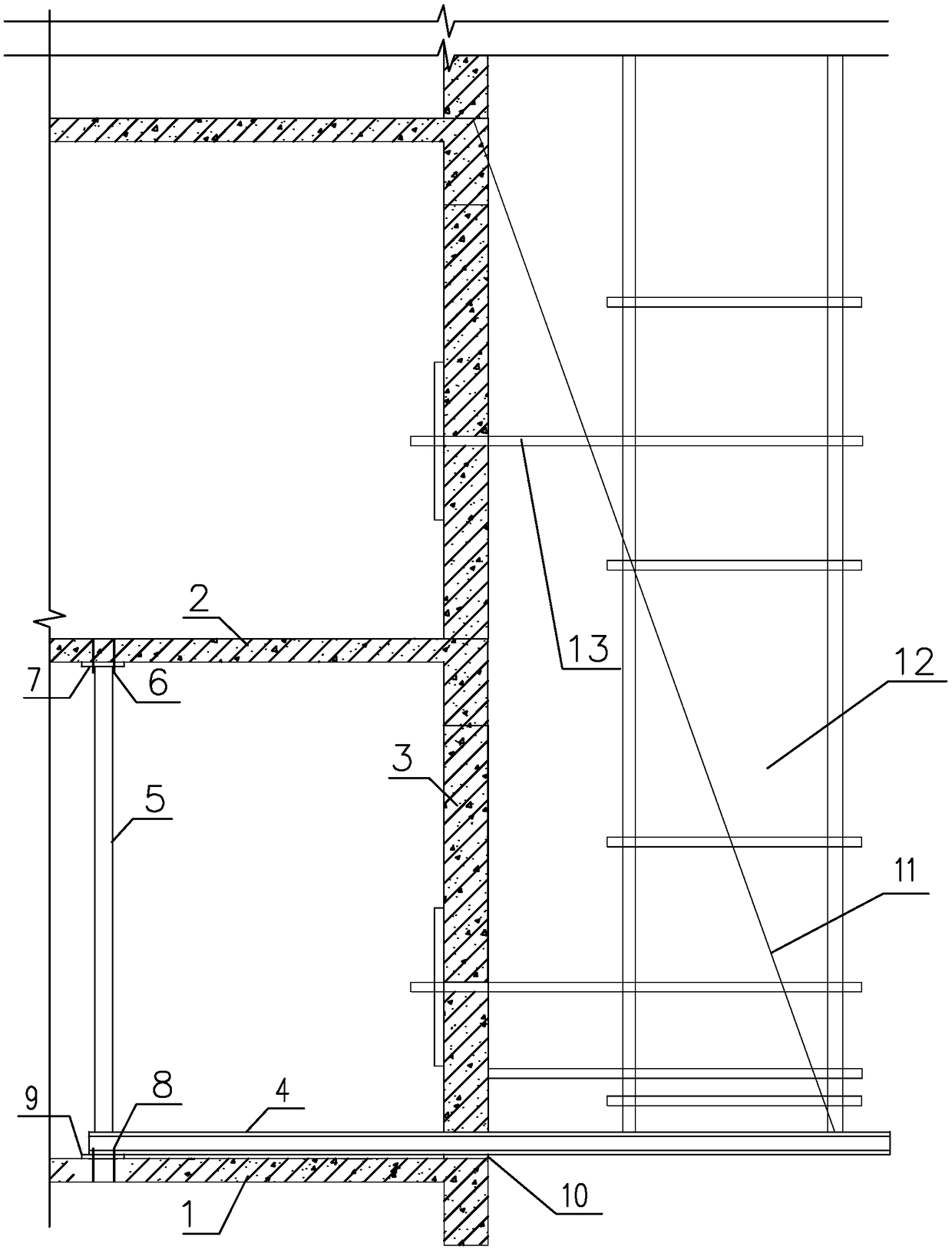

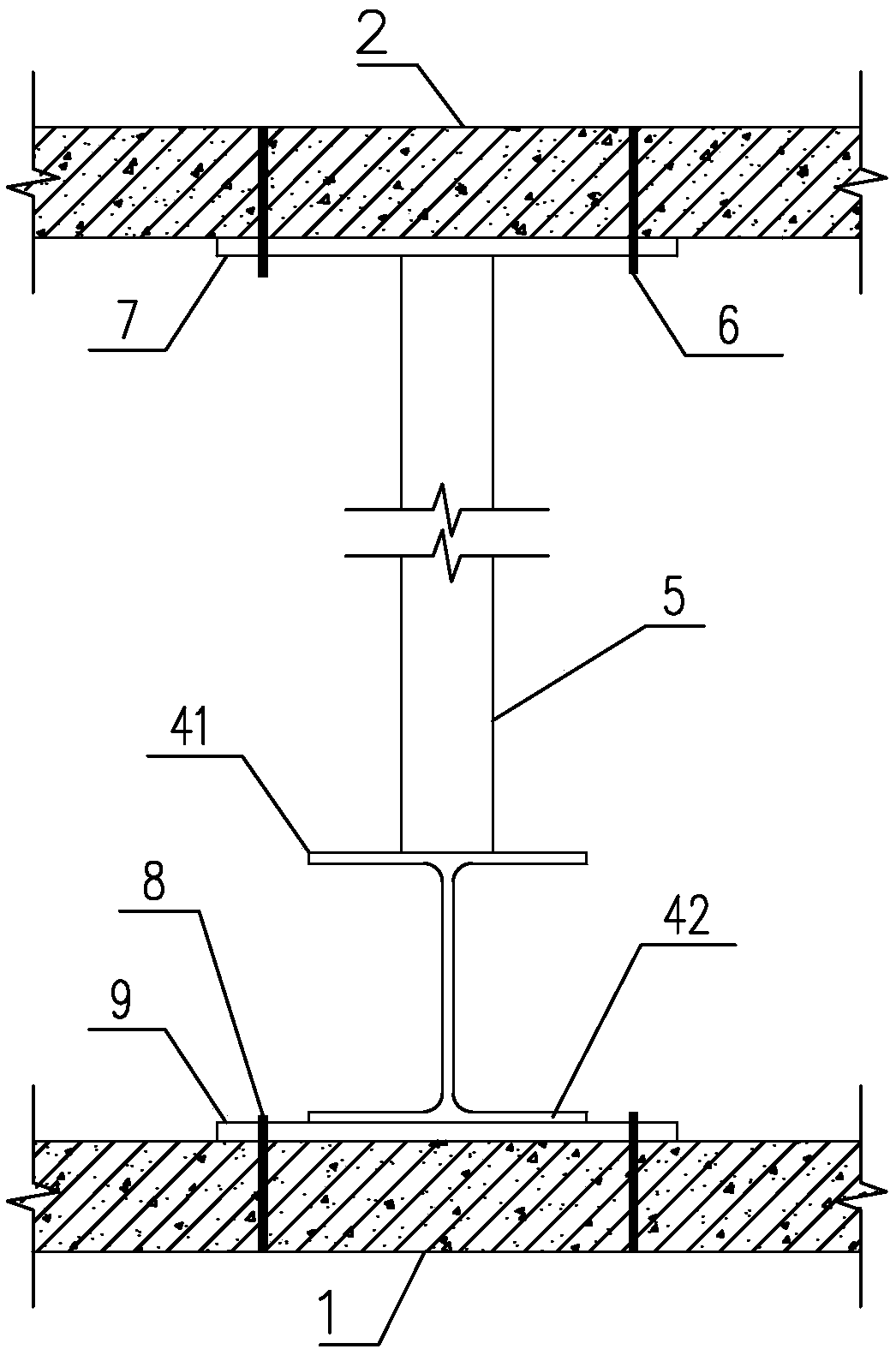

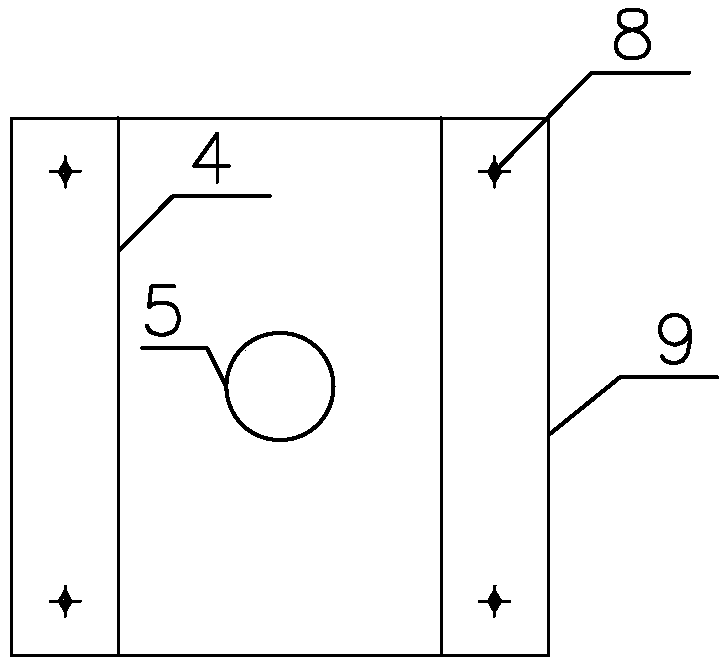

[0035] Such as Figure 1~3 As shown, it is a rear H-shaped steel cantilevered scaffold of the present invention, including a scaffold main body 12, steel pipe 5, H-shaped steel 4, steel wire rope 11, upper steel plate 7 and a pair of lower steel plates 9, 10, H-shaped steel 4 is arranged horizontally, H The lower flange 42 of the inner end of the shaped steel 4 is welded on the lower steel plate 9, and the lower steel plate 9 is connected with the existing concrete floor 1 of the lower floor through chemical bolts 8, so that the existing concrete floor 1 of the lower floor bears part of the force transmitted by the H-shaped steel; Existing wall 3 passes through to form a cantilever section, and the lower steel plate 10 is arranged on the bottom surface of the opening of the existing wall 3 for the H-shaped steel 4 to pass through, and the lower flange 42 of the part where the H-shaped steel 4 passes through the opening is pressed Tightly on this lower steel plate 10. The scaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com