alc decorative insulation integrated wall panel

A wallboard and plate technology, which is applied in the direction of construction, building components, building structure, etc., can solve the problems of high wall cost, reduced investment in foundation and structure, inconvenient secondary decoration, etc., to achieve convenient construction, reduce foundation and structure, etc. Investment, good economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

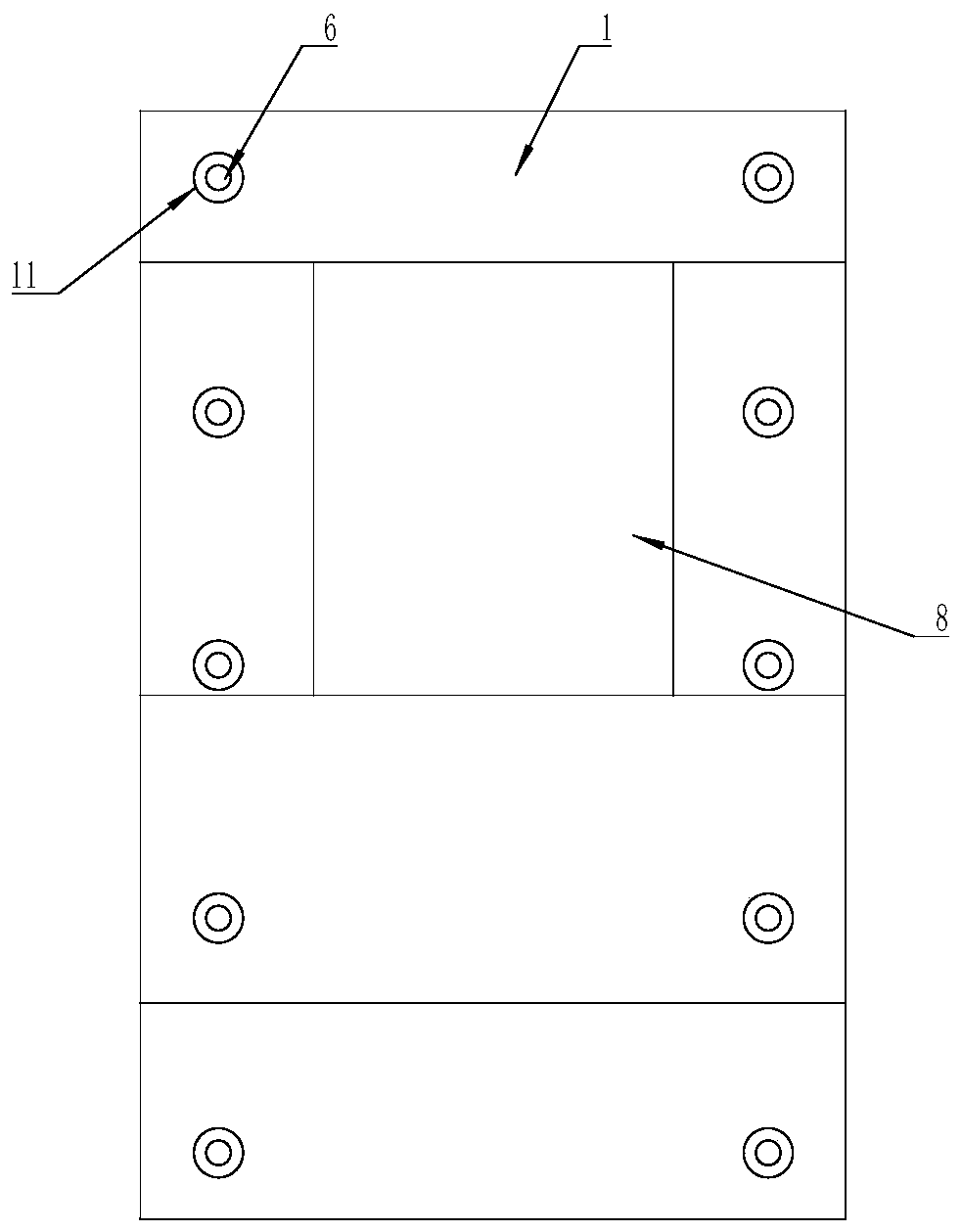

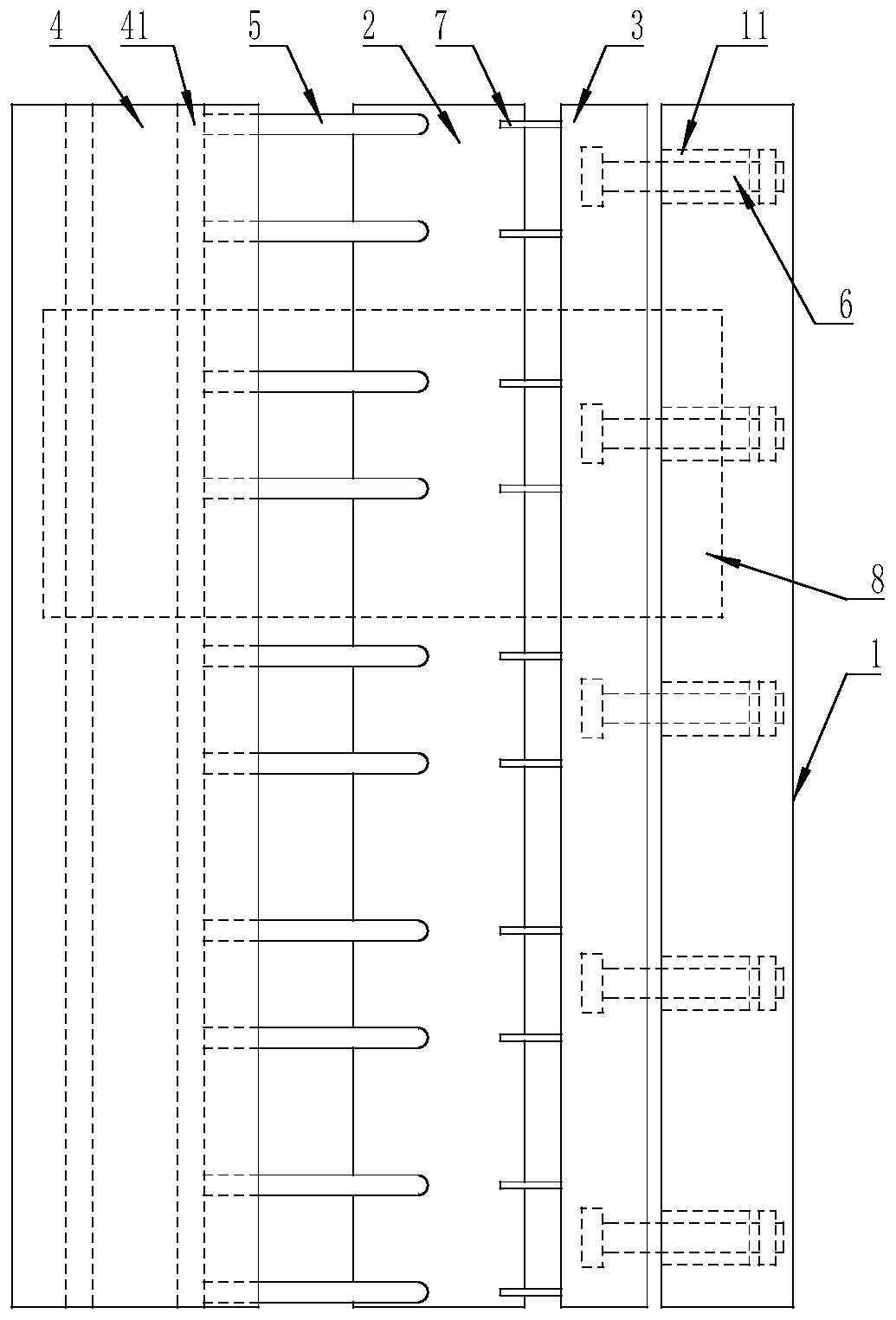

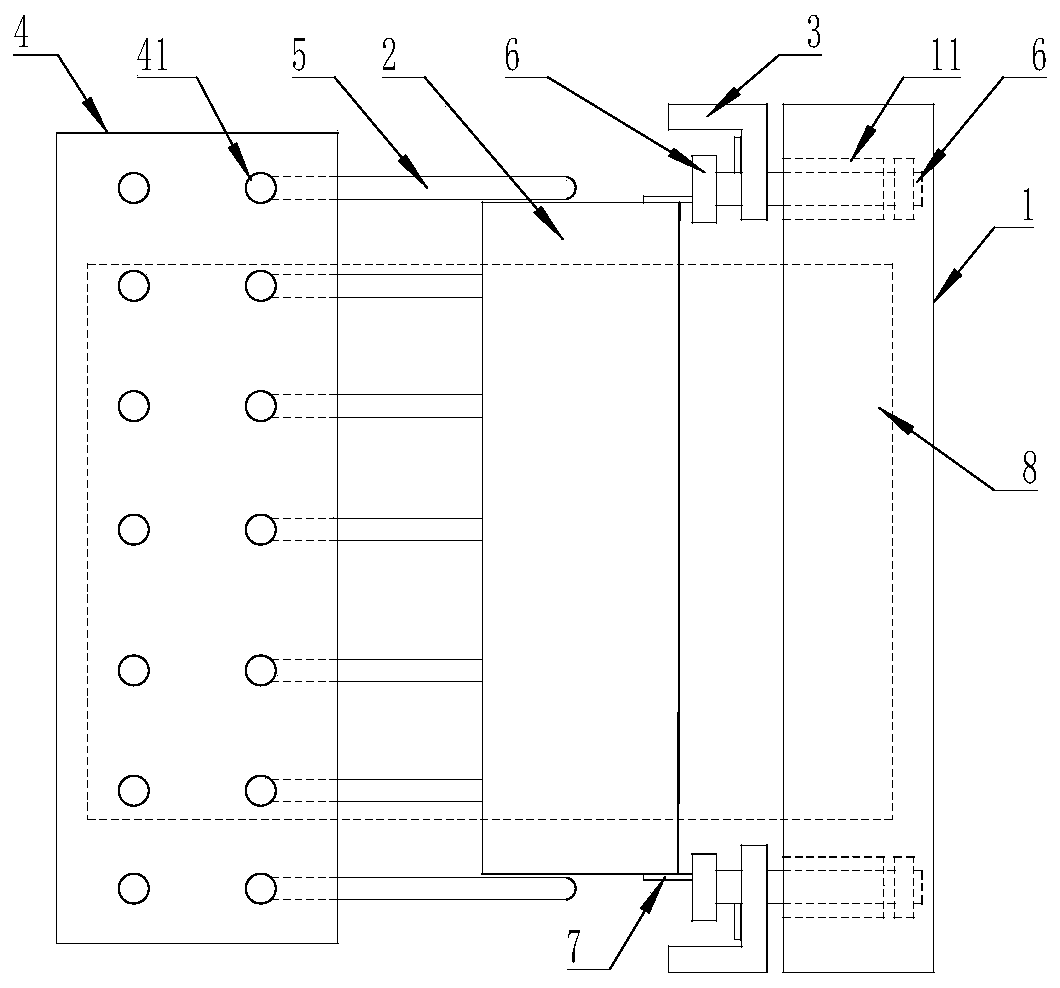

[0024] The glass fiber board 1 has a rectangular parallelepiped structure, two rows of fixing holes 11 are symmetrically distributed on both sides of the front end of the glass fiber board 1 , the autoclaved aerated concrete board 4 is arranged behind the glass fiber board 1 , and the outer surface of the autoclaved aerated concrete board 4 is provided with carved patterns and decoration patterns, at least two rows of longitudinal steel bars 41 are arranged in the autoclaved aerated concrete slab 4, and a rectangular frame 2 is set between the front end of the autoclaved aerated concrete slab 4 and the rear end of the glass fiber board 1, and the frame 2 is made of iron. quality, a front connection mechanism is set between the front end face of the frame 2 and the rear end face of the fiberglass board 1;

[0025] The structure of the front connection mechanism is as follows: both sides of the rear end surface of the glass fiber board 1 are provided with longitudinal reinforcing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com