Horizontal overturning door

A flap door and door panel technology, which is applied in water conservancy projects, sea area projects, coastline protection, etc., can solve the problems that the curved arm steel dam gate cannot be installed and used in parallel with multiple leaves, the structure is complicated and complicated, and the four-bar structure is complicated. , to achieve simple structure, reduce energy consumption, and avoid the impact of water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

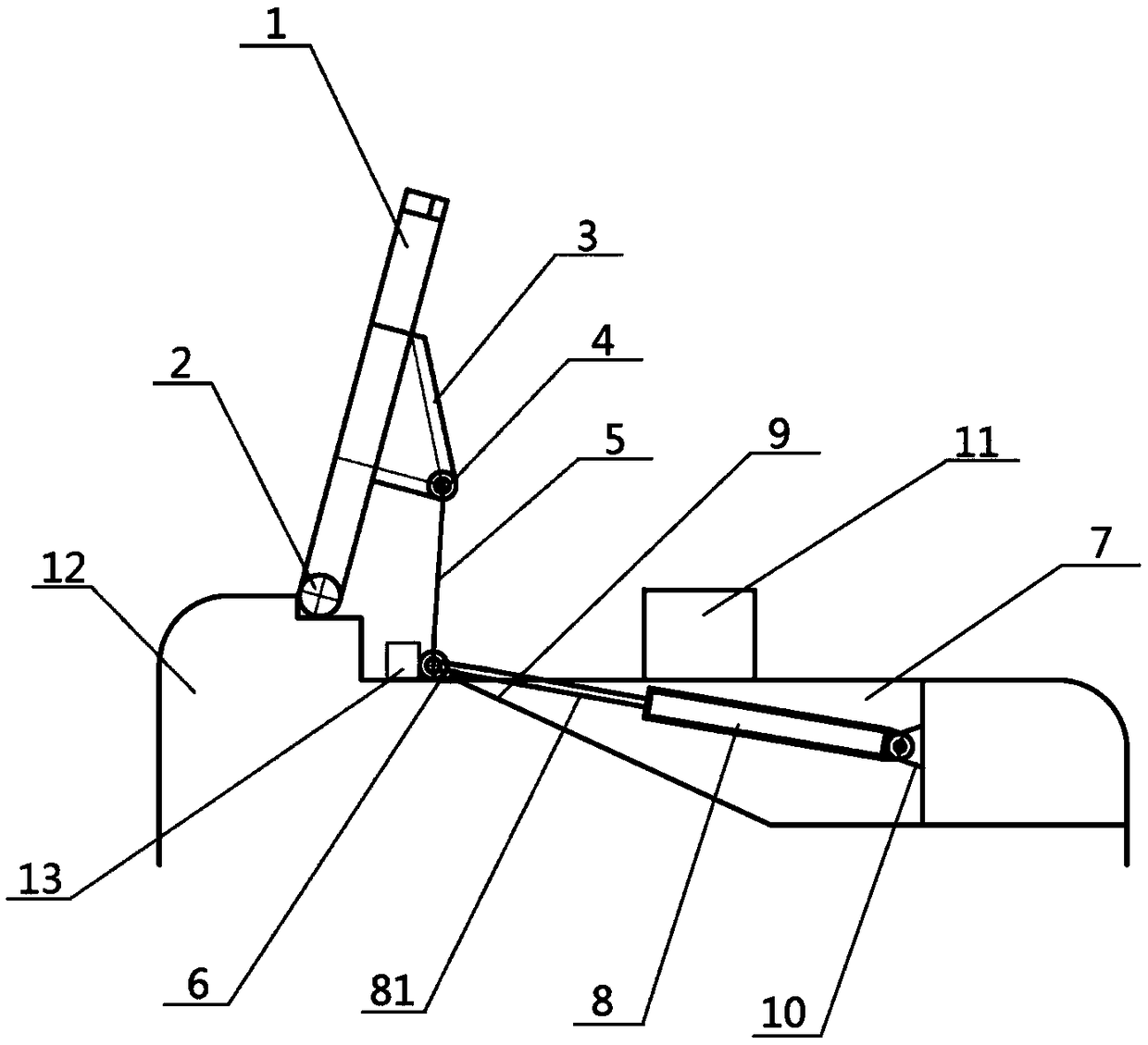

[0036] Such as figure 1As shown, when it is necessary to lift the dam and stop water, the opening and closing cylinder 8 is started, and the control piston rod 81 is stretched out from the opening and closing cylinder 8, and the movable joint 6 of the support rod is pushed to move upward along the sliding track 9, and the support rod 5 passes through the support The hinge 4 jacks up the door panel 1 originally horizontally mounted on the pier 11, and the door panel 1 starts to swing up around the bottom shaft 2, and the piston rod 81 pushes the movable joint 6 of the support rod to the uppermost edge of the sliding track 9. At this time, the support rod 5 and the The horizontal planes are 80-88°. In order to prevent the piston rod 81 from pushing the support rod movable joint 6 over the head, a support rod limit column 13 is formed on the slide track 9 along the other side of the support rod movable joint 6 . The support rod movable joint 6 cannot be pushed forward after bein...

Embodiment 2

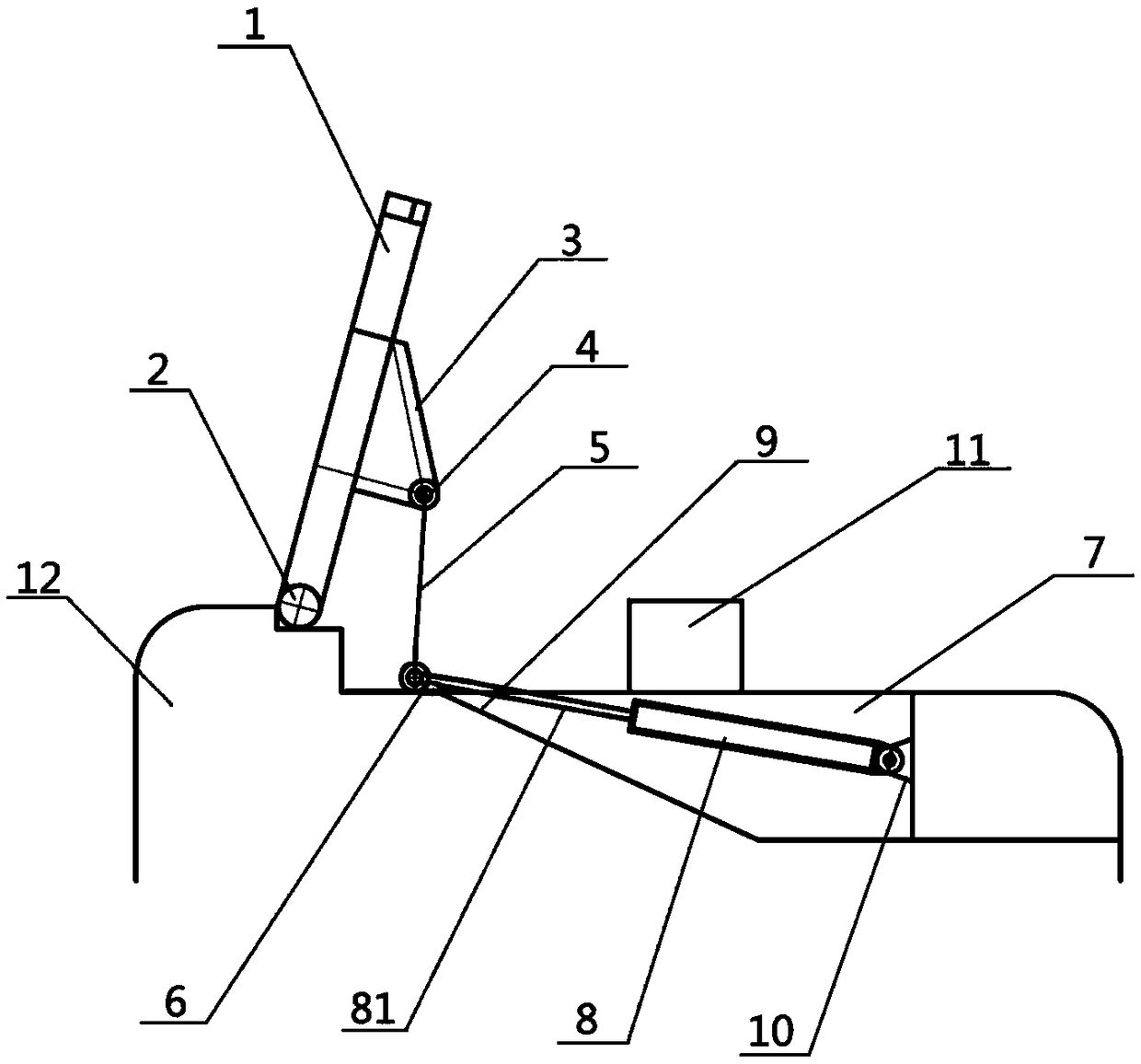

[0039] Such as image 3 As shown, in this embodiment, the maximum amount of the extension length of the piston rod 81 is the length to push the support rod movable joint 6 to the position in Embodiment 1 when the operation of raising the dam and blocking water is completed. When the piston rod 81 extends When the amount is the largest, it is 80-88° between the support rod 5 and the horizontal plane. Therefore, in this embodiment, there is no need for the support rod limiting post 13 . When it is necessary to raise the dam and stop the water, the opening and closing cylinder 8 is activated, and the control piston rod 81 protrudes from the opening and closing cylinder 8 to push the movable joint 6 of the support rod to move upward along the sliding track 9, and the support rod 5 is lifted by the bracket hinge 4. Lift the door panel 1 that was originally placed on the support pier 11, and the door panel 1 starts to swing up around the bottom shaft 2, and the piston rod 81 pushes...

Embodiment 3

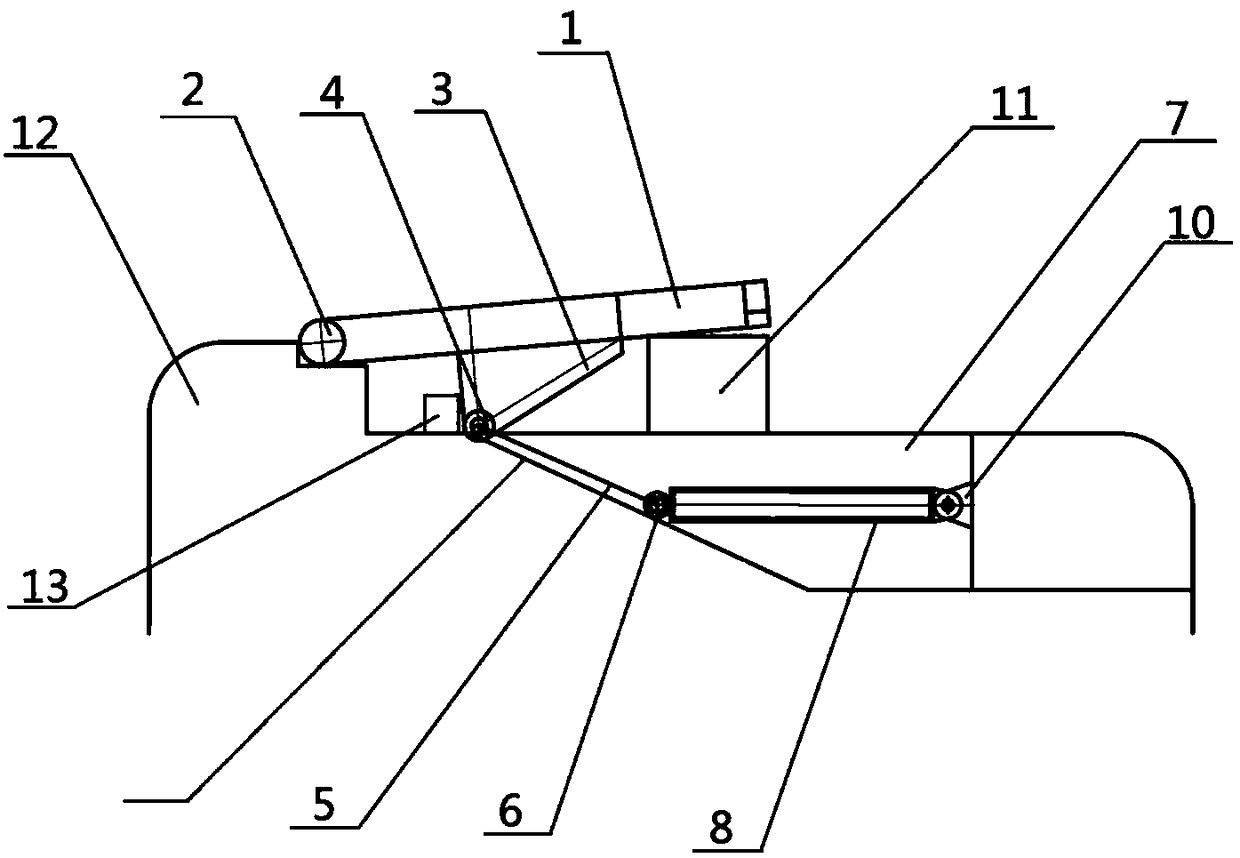

[0042] In this embodiment, the bracket hinge 4 is directly installed on the back surface of the door panel 1, compared with the embodiment 1, the bracket 3 is omitted, and other structures are consistent with the embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com