Water conservancy gate

A gate and water conservancy technology, which is applied in the field of water conservancy engineering, can solve problems such as inconvenient use, rusty mechanical structure of water gates, shortened service life of water conservancy gates, etc., and achieve the effect of reasonable and firm structure, firm overall structure and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

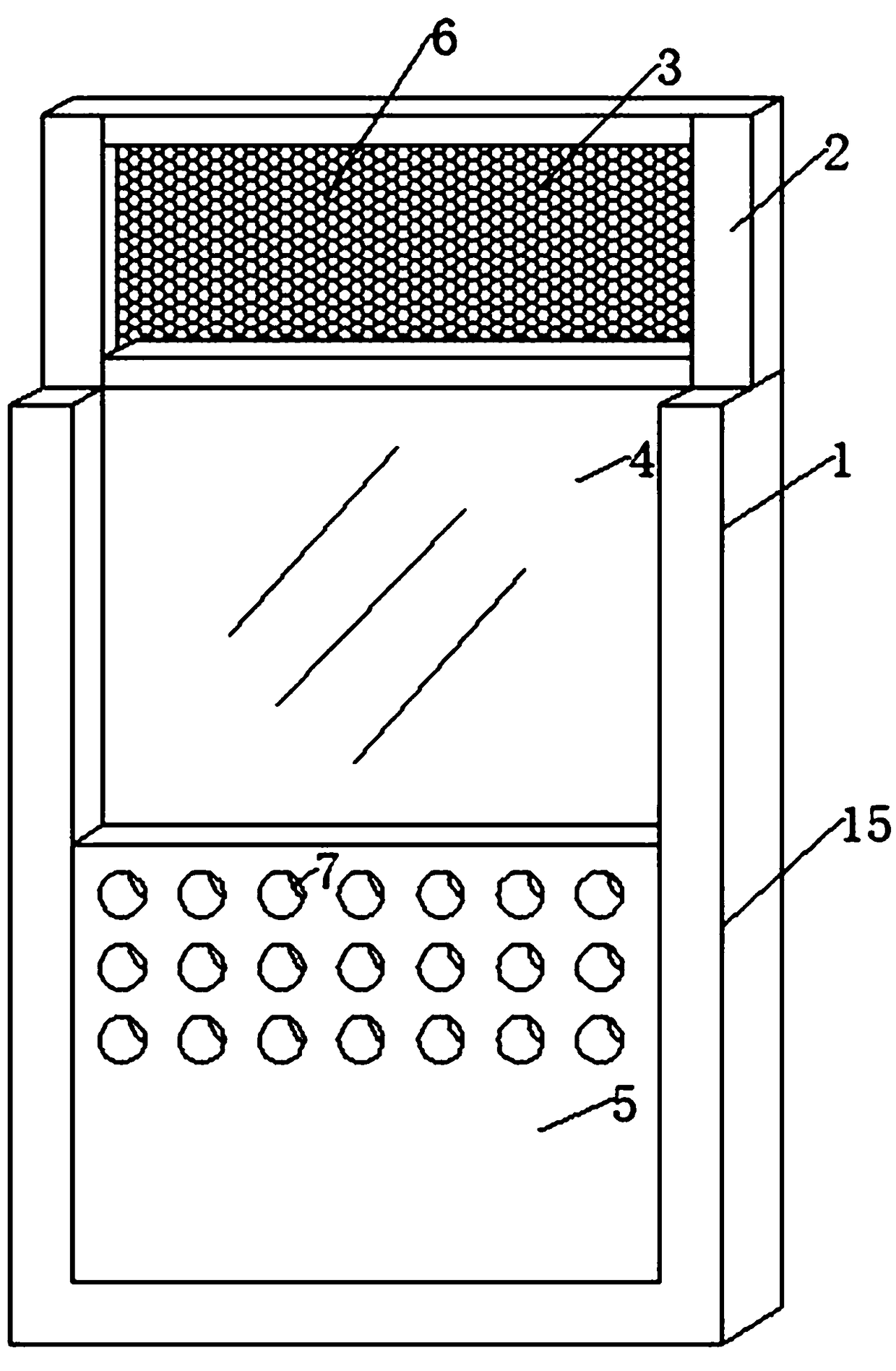

[0025] see Figure 1-4 , a water conservancy gate, comprising a fixed frame 1 and a gate plate 6, the top of the fixed frame 1 is provided with an extension frame 2, the extension frame 2 is in the shape of a mouth, and the inner side of the extension frame 2 is embedded with a filter screen 3, the Filter holes 6 are uniformly distributed inside the filter screen 3, an orientation groove 9 is provided inside the fixed frame 1, a fixed gate plate 5 is provided on one side of the fixed frame 1, and a first drain is provided on the top of the fixed gate plate 5. The hole area 7, the first leakage hole area 7 occupies 1 / 2 of the total area of the fixed gate plate 5, the top of the fixed gate plate 5 is provided with a movable gate plate 4, and the height of the movable gate plate 4 is 1 2 / 3, and the bottom of the movable gate plate 4 is provided with a second leakage area 8, the number and size of the leakage holes 8 in the second leakage area are the same as the number and size...

Embodiment 2

[0027] A water conservancy gate, comprising a fixed frame 1 and a gate plate 6, the top of the fixed frame 1 is provided with an extension frame 2, the extension frame 2 is in the shape of a mouth, and the inside of the extension frame 2 is embedded with a filter screen 3, the Filter holes 6 are evenly distributed inside the filter screen 3, an orientation groove 9 is provided inside the fixed frame 1, a fixed gate plate 5 is provided on one side of the fixed frame 1, and a first leakage hole is provided on the top of the fixed gate plate 5 Zone 7, the first leakage hole zone 7 occupies 1 / 2 of the total area of the fixed gate plate 5, the top of the fixed gate plate 5 is provided with a movable gate plate 4, and the height of the movable gate plate 4 is the height of the fixed frame 1 2 / 3, and the bottom of the movable gate plate 4 is provided with a second leakage area 8, the number and size of the leakage holes 8 in the second leakage area are the same as the number and siz...

Embodiment 3

[0030] A water conservancy gate, comprising a fixed frame 1 and a gate plate 6, the top of the fixed frame 1 is provided with an extension frame 2, the extension frame 2 is in the shape of a mouth, and the inside of the extension frame 2 is embedded with a filter screen 3, the Filter holes 6 are evenly distributed inside the filter screen 3, an orientation groove 9 is provided inside the fixed frame 1, a fixed gate plate 5 is provided on one side of the fixed frame 1, and a first leakage hole is provided on the top of the fixed gate plate 5 Zone 7, the first leakage hole zone 7 occupies 1 / 2 of the total area of the fixed gate plate 5, the top of the fixed gate plate 5 is provided with a movable gate plate 4, and the height of the movable gate plate 4 is the height of the fixed frame 1 2 / 3, and the bottom of the movable gate plate 4 is provided with a second leakage area 8, the number and size of the leakage holes 8 in the second leakage area are the same as the number and siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com