A kind of rigid polyurethane foam material for refrigerator and preparation method thereof

A technology of rigid polyurethane and foam materials, applied in the field of polyurethane foam plastics, can solve the problems of foam bulging on the back panel of the refrigerator, the decrease of the thermal insulation performance of the refrigerator, and the destruction of the aesthetics of the refrigerator design, and achieves shortened production cycle, fast demoulding speed, and curing expansion. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

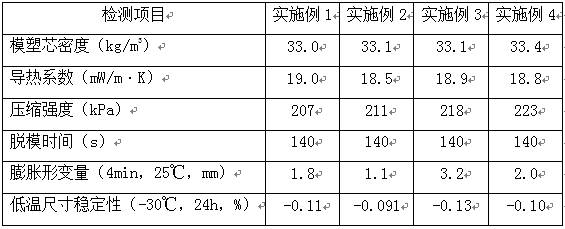

Examples

Embodiment 1

[0037] Rigid polyurethane insulation materials for refrigerators are composed of white material and black material, the weight ratio of white material to black material is 1:1.08, of which:

[0038] The polyol composition in the white material has a total of 100 parts by weight, including: 40 parts by weight of o-toluenediamine polyether polyol, 30 parts by weight of sorbitol polyether polyol, 20 parts by weight of glycerol polyether polyol, castor oil polyether polyol 5 parts by weight of alcohol, and 5 parts by weight of Bayer's 2601 polyester polyol.

[0039] In addition, there are 3.5 parts by weight of foam stabilizer in the white material; 1.5 parts by weight of water; 2.5 parts by weight of composite catalyst, including 0.3 parts by weight of bis(dimethylaminohexyl) ether (A-1), 1.5 parts by weight of methylcyclohexylamine (PC-8), 0.7 parts by weight of 2,4,6-tris(dimethylaminomethyl)phenol (TMR-30); 20 parts by weight of blowing agent, of which cyclopentane, The mass ...

Embodiment 2

[0043] Rigid polyurethane insulation materials for refrigerators are composed of white material and black material, the weight ratio of white material to black material is 1:1.15, of which:

[0044] The polyol composition in the white material has a total of 100 parts by weight, including: 35 parts by weight of o-phenylenediamine polyether polyol, 35 parts by weight of sorbitol polyether polyol, 15 parts by weight of glycerol polyether polyol, castor oil polyether polyol 10 parts by weight of alcohol, and 5 parts by weight of Bayer's 2602 polyester polyol.

[0045] In addition, there are 3 parts by weight of foam stabilizer in the white material; 2.0 parts by weight of water; 3 parts by weight of composite catalyst, of which 0.3 parts by weight of pentamethyldiethylenetriamine (PC-5), bis(dimethylamino Hexyl) ether (A-1) 0.2 parts by weight, trihexylenediamine (TEDA-33P) 1.0 parts by weight, N,N-dimethylcyclohexylamine (PC-8) 0.5 parts by weight, 1,3, 0.5 parts by weight of 5...

Embodiment 3

[0049] Rigid polyurethane insulation materials for refrigerators are composed of white material and black material, the weight ratio of white material and black material is 1:1.20, of which:

[0050]The polyol composition in the white material has a total of 100 parts by weight, including: 30 parts by weight of o-toluenediamine polyether polyol, 40 parts by weight of sorbitol polyether polyol, 10 parts by weight of glycerol polyether polyol, castor oil polyether polyol 5 parts by weight of alcohol, and 15 parts by weight of Bayer's 2602 polyester polyol.

[0051] In addition, there are 2 parts by weight of foam stabilizer in the white material; 2.0 parts by weight of water; 2 parts by weight of composite catalyst, including 0.3 parts by weight of pentamethyldiethylenetriamine (PC-5), (TMHDA) 1.5 parts by weight, methylquaternary ammonium salt (TMR-2) 0.2 parts by weight; blowing agent 20 parts by weight, wherein the mass ratio of cyclopentane, isopentane and HFC-245fa is 45:10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com