Electrical heating perforating device for aluminum foil composite film

A technology of composite film and punching device, which is applied in metal processing and other directions, can solve the problems of inconvenient reception and low efficiency of punching operation, and achieve the effect of improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0022] The technical scheme of concrete implementation of the present invention is:

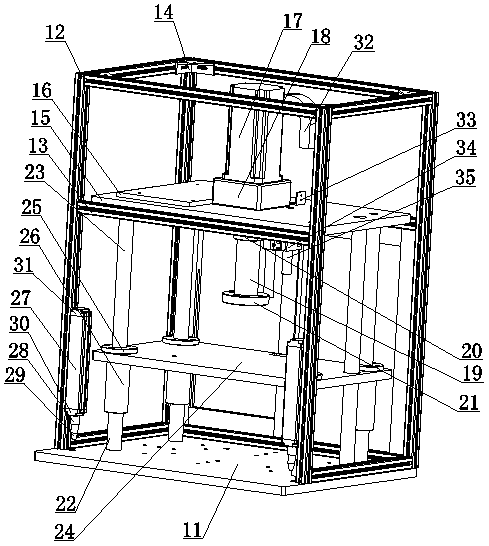

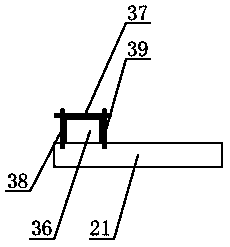

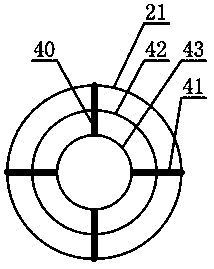

[0023] Such as Figure 1 to Figure 4 Shown, a kind of electrothermal punching device of aluminum foil composite film comprises base plate 11, and base plate 11 is provided with bracket 12, and the upper part of bracket 12 is provided with positioning frame 13, and positioning frame 13 is provided with positioning plate 15, and positioning plate 15 is provided with There is a hydraulic cylinder 17, the positioning plate 15 is provided with a positioning seat 18, the hydraulic cylinder 17 is installed on the positioning seat 18, the bottom of the hydraulic cylinder 17 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com