Gas cyclone pollutant collecting culture pond system

A technology of aquaculture ponds and flow sets, applied in the field of aquaculture pond systems, can solve the problems of easy to cause turbulence, low water flow stability, low sewage absorption efficiency, etc., and achieve stable water inlet dynamics, high water flow stability, and drainage stability. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0035] In traditional aquaculture ponds, construct a high-efficiency sewage collection circular aquaculture pond system according to 4-6% of the pond water surface area. The water depth is not less than 2.0m, which is used for high-density intensive cultivation of fish, and the rest of the pond area is used as a water purification area. The discharge water from the high-efficiency sewage collection circular aquaculture pond system is purified by the water purification zone and returned to the circular pond for reuse to realize the internal circulation of the water body.

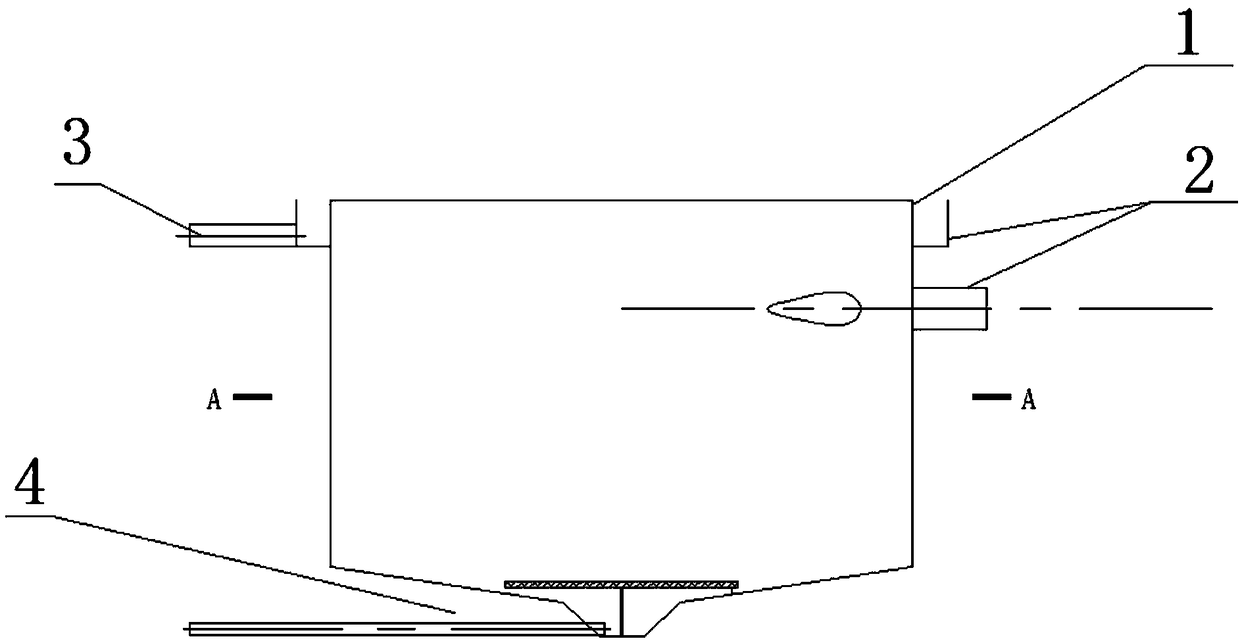

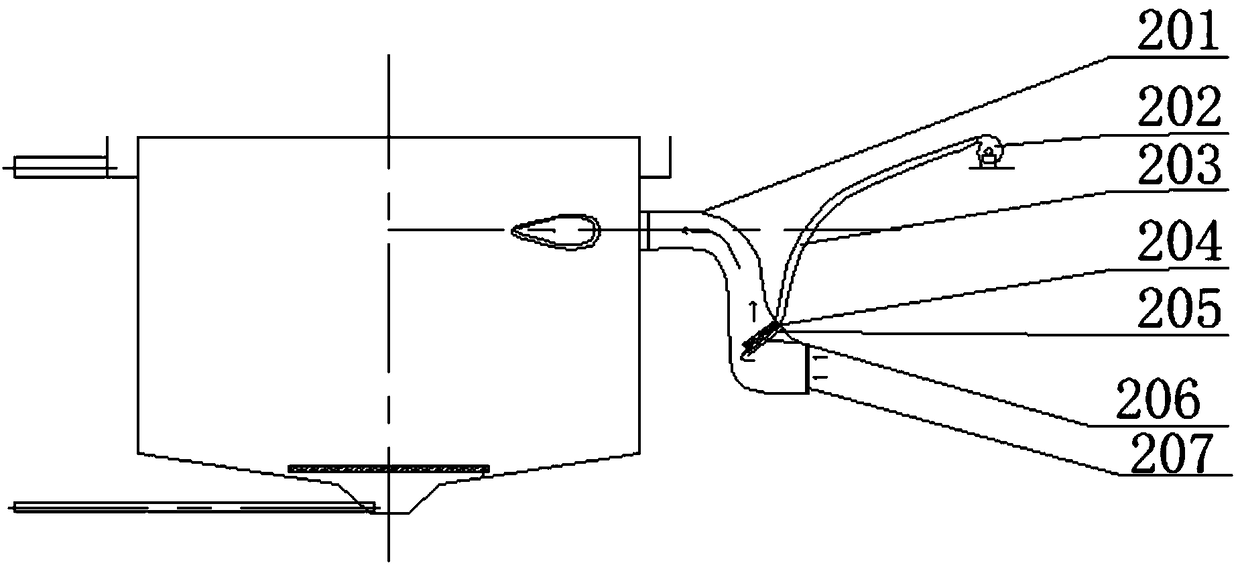

[0036] The culture pond system includes a circular culture pond body 1, an inflow aeration pushing flow system 2, an upper drainage system 3, and a bottom sewage system 4; the bottom of the circular culture pond body 1 is inclined towards the central sewage pit; The water inle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com