Semiconductor wafer cleaning and drying device

A technology for drying equipment and semiconductors, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc. It can solve the problems of easy fragments and contamination of wafers, residual water marks on wafers, and potential safety hazards, so as to reduce fire safety Hidden dangers, preventing damage to wafers, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

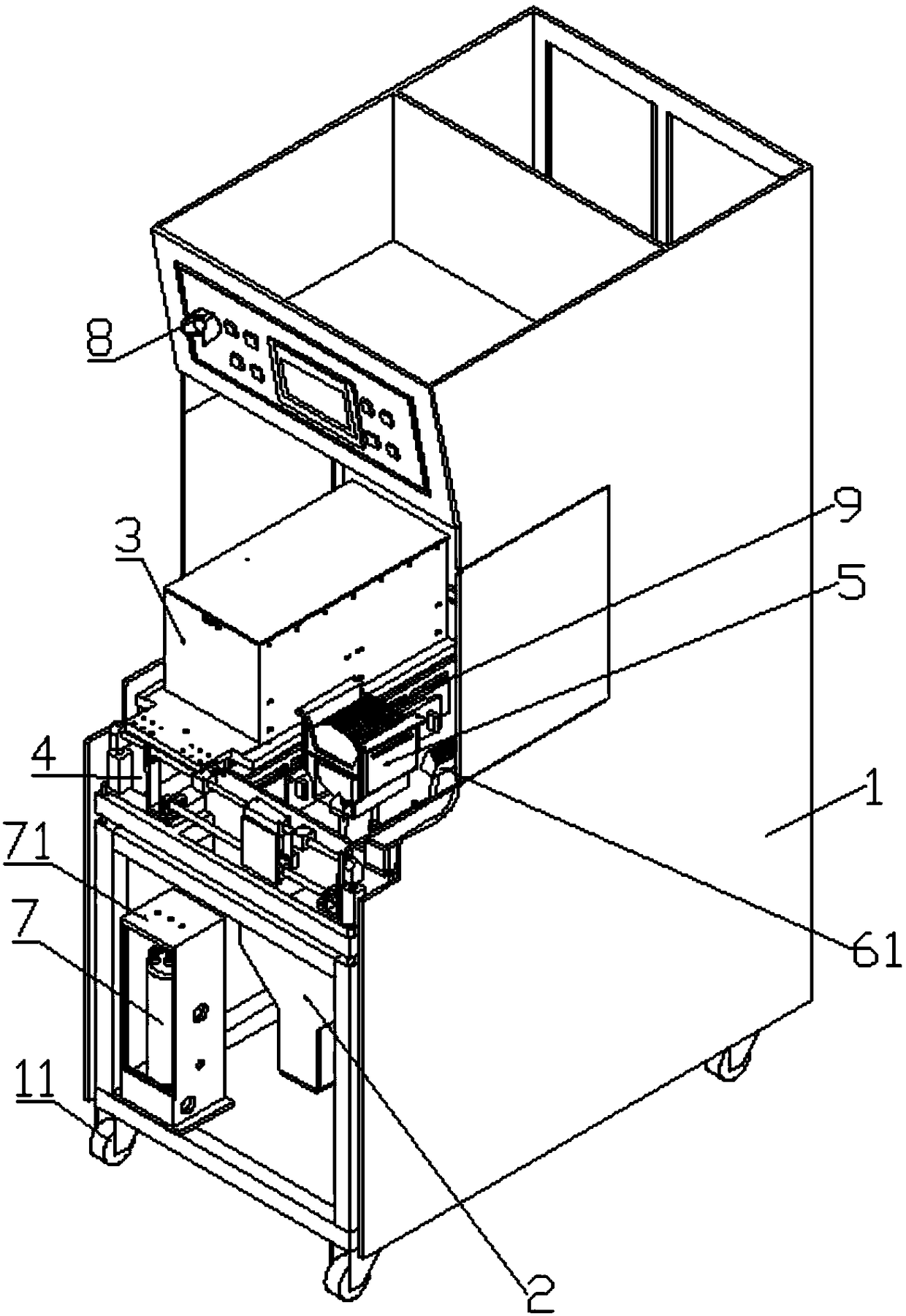

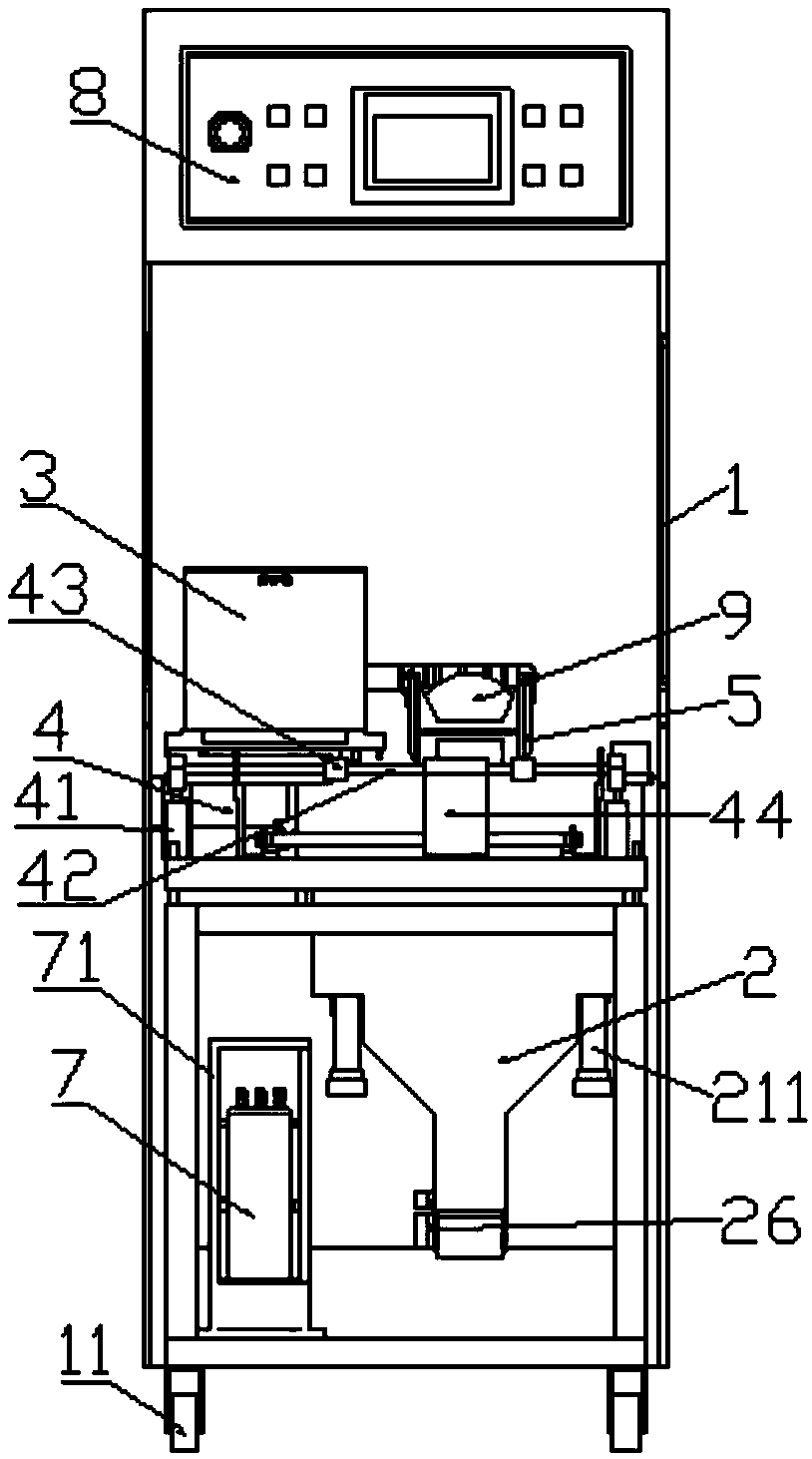

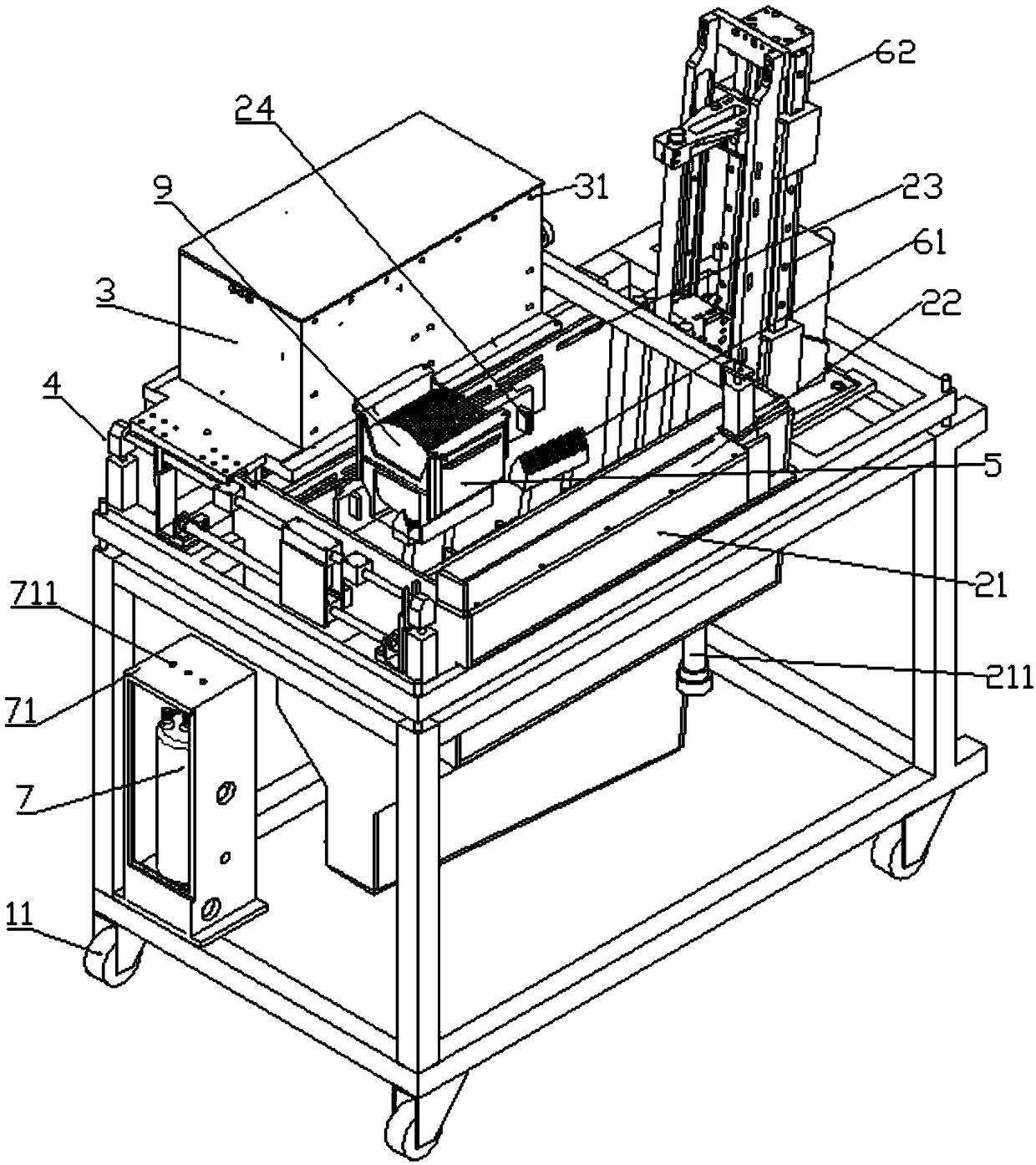

[0030] Such as Figure 1-6 As shown, a semiconductor wafer cleaning and drying equipment includes an equipment main body 1, a water tank 2, a cover tank 3, a cover tank moving mechanism 4 connected to the cover tank 3, a wafer placing flower basket 5 movable in the water tank 2, an upper and lower The running mechanism 6, the IPA bottle 7 and the control panel 8, the water tank 2 is fixed on the equipment main body 1, the height of the bottom surface of the cover tank 3 is consistent with the height of the top of the water tank 2, the cover tank moving mechanism 4 is located at both ends of the water tank 2, the water tank 2 An overflow tank 21 is fixed on the outside, a cover plate 22 is fixed above the overflow tank 21, a waste water discharge pipe 211 is provided at the bottom of the overflow tank 21, an overflow port 23 communicating with the overfl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com