Wireless joint debugging and testing system of wind turbine generator system

A technology for wind turbines and test systems, which is applied in wind turbine test runs, wind power generation, etc., can solve problems such as shape and design restrictions, waste, and test data query errors, and achieve easy mobility, reduce terrain effects, and operate easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

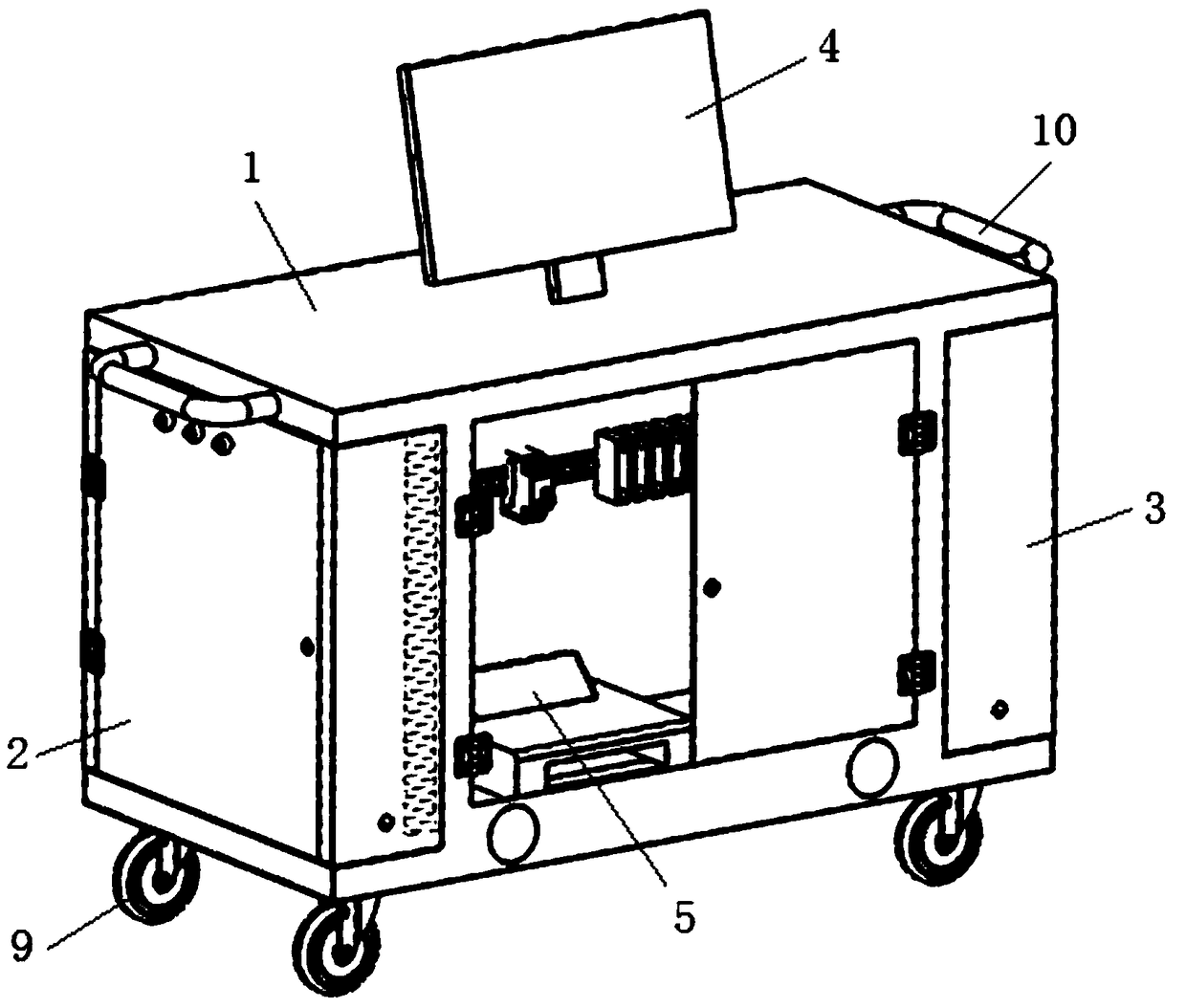

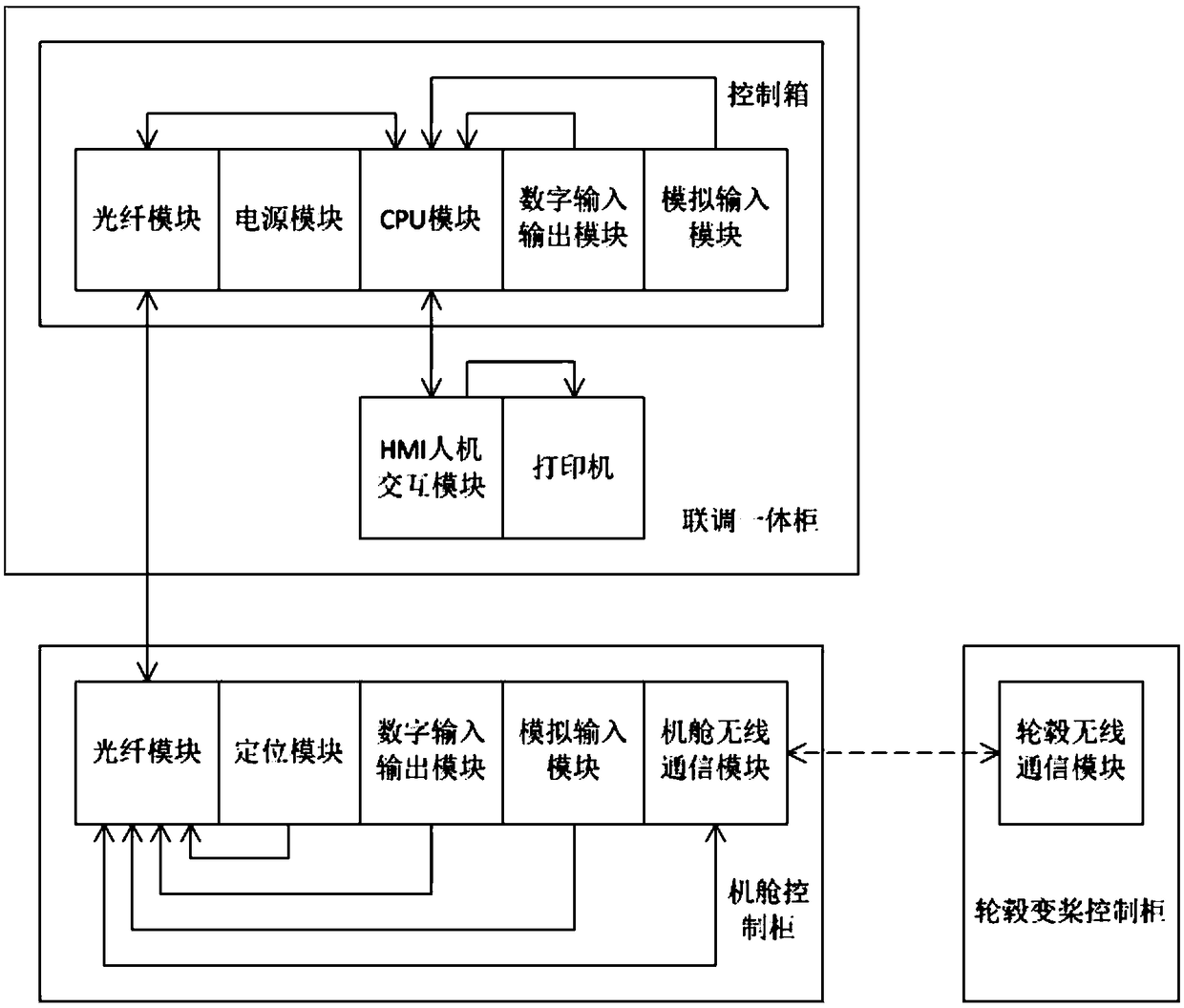

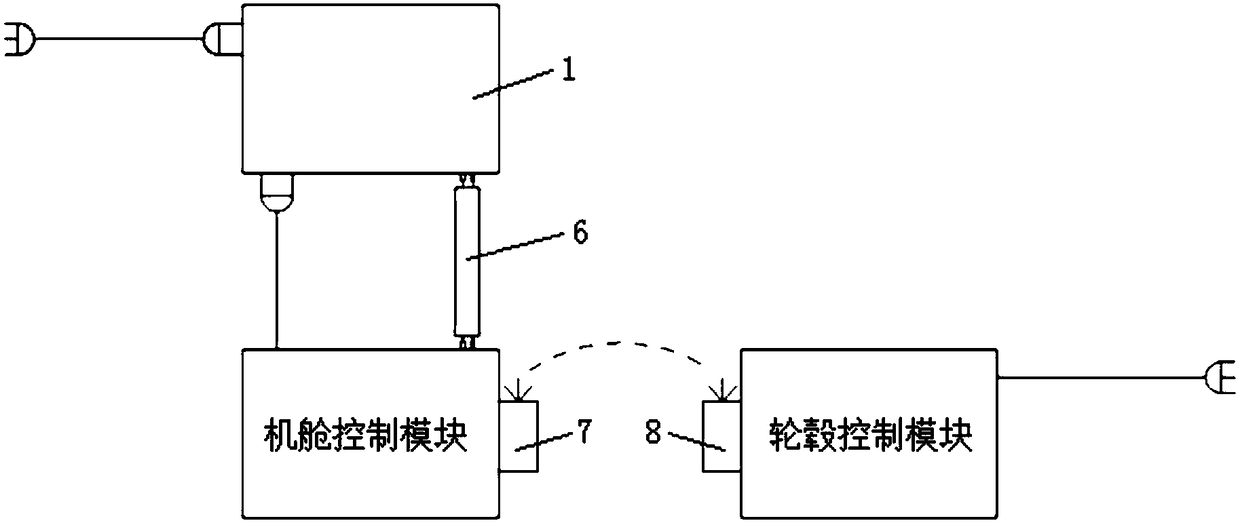

[0033] Such as Figures 1 to 3 As shown, a wireless joint debugging test system for wind power generators includes a joint debugging integrated cabinet 1, control boxes 2 and 3, a touch screen 4, a cabin wireless communication module, a wheel hub wireless communication module and a printer 5, a printer 5, a control box 2, 3 and the touch screen 4 are set on the integrated debugging cabinet 1. Casters 9 are provided at the bottom of the integrated debugging cabinet 1 , and handles 10 are provided at the side of the cabinet.

[0034] There are two control boxes, namely 1.5MW type control box 2 and 2MW type control box 3. The internal components of the two control boxes are the same, and they are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com