Close distance caisson group sinking construction method

A construction method and short-distance technology, applied in the direction of caisson, foundation structure engineering, foundation structure test, etc., can solve the problems of low construction efficiency of caisson tilting accidents, reduce mutual influence and ensure smooth sinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

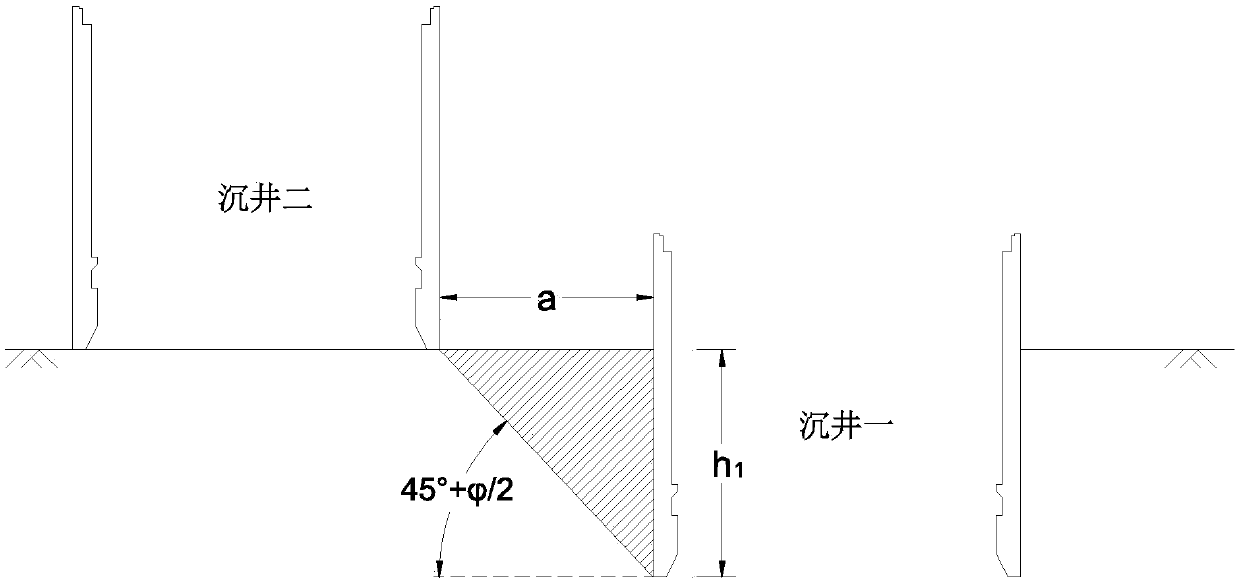

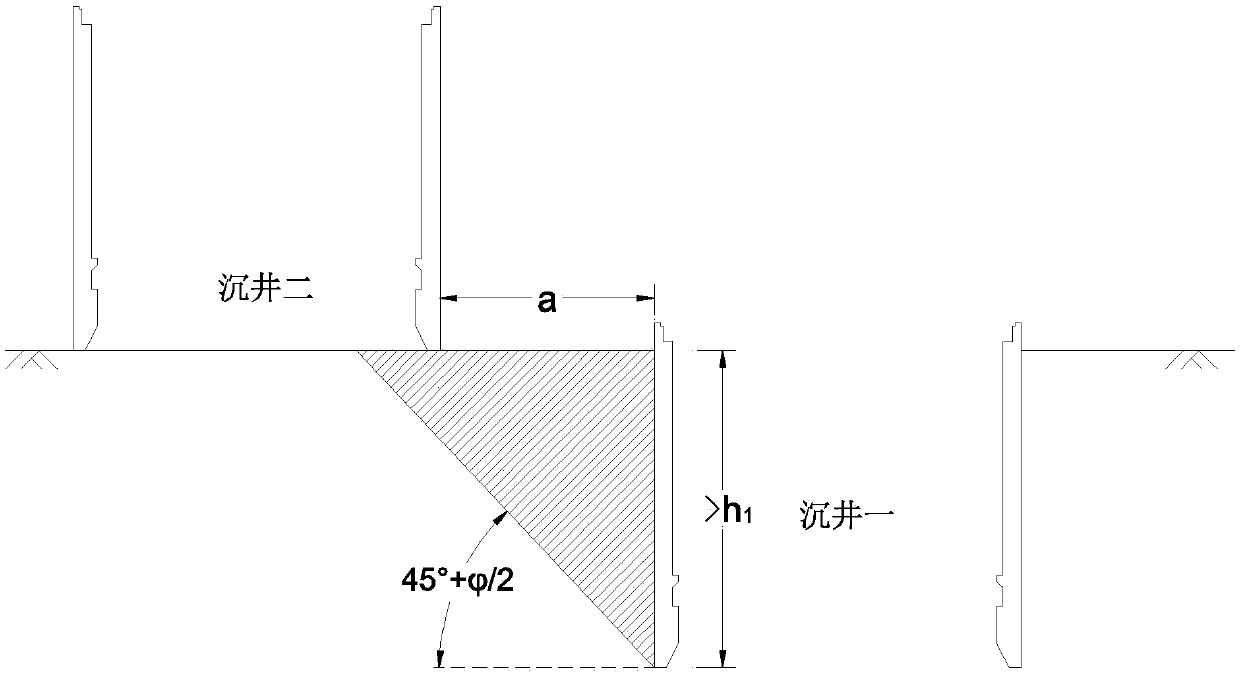

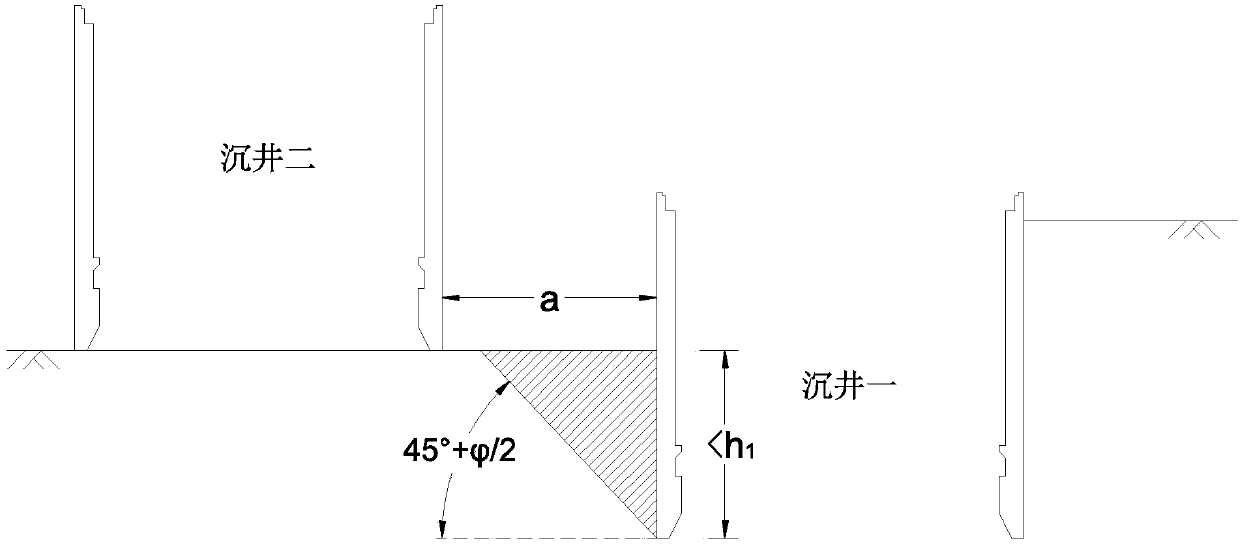

[0037] This embodiment provides a close-range caisson group sinking construction method, including: determining the minimum horizontal clear distance a of adjacent caissons in the caisson group; The vertical depth h of the soil sliding surface when the horizontal width of the soil sliding surface is a 1 ; Consider the vertical load of the self-weight of the caisson as a local additional load, and the vertical stress of the self-weight of the caisson diffuses downward, and calculate the vertical depth h of the downward diffusion of the vertical stress at the horizontal clear distance a 2 ;Determine the safety height difference H of the blade foot of adjacent caissons in the construction of caisson group, where H1 , h 2}; The adjacent caissons in the caisson group are alternately submerged to complete the sinking construction and back-sealing construction of the caissons, and the height difference of the edge foot of the adjacent caissons is always controlled within the range of...

Embodiment 2

[0055] In a certain bidding section of a certain pumping station project, there are 3 circular water intake wells at the water intake head, all of which are of reinforced concrete structure. The circular water intake well has an inner diameter of 12m, an outer diameter of 13.4m, a total height of 12.5m, and a wall thickness of 0.7m. It is constructed by caisson method. The caissons are numbered as No. 1 caisson, No. 2 caisson and No. 3 caisson from west to east. The center distance between adjacent caissons is 21.0m, and the net distance is 7.6m. The caisson is sunk by crane and small excavator, and the sinking depth is 12.5m. Due to the extremely small net distance between caissons, it is very easy to cause the adjacent caissons to incline.

[0056] Before construction, determine the minimum horizontal clear distance a=7.6m between adjacent caissons in the caisson group; take the value of internal friction angle of the silty clay layer Calculated, According to the addit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com