Moxa cake and preparation process thereof

A preparation process and technology of moxa cake, applied in the field of moxa cake and its preparation, can solve the problems of low utilization rate of moxa, pollution of body surface, loss, etc., and achieve the effect of improving the utilization rate of moxa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

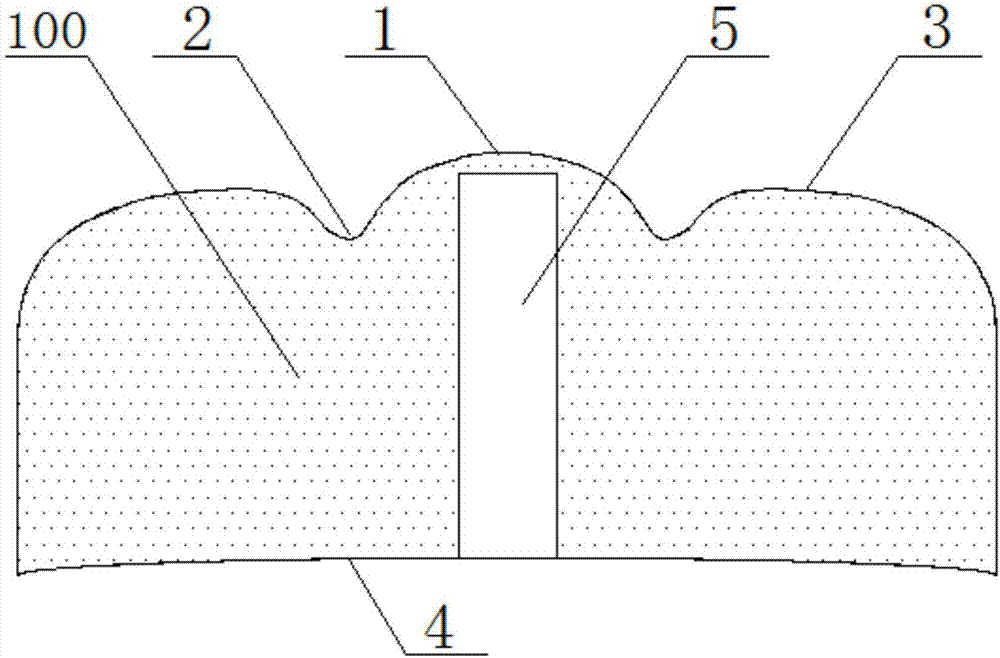

[0031] A moxa cake, pressed from moxa, with a density of 0.51g / cm 3 , see figure 1 , the moxa cake 100 is in the shape of a round cake as a whole, with a diameter of 20 mm and a height of 8 mm; the center of the upper surface of the moxa cake 100 is raised, higher than the upper surface 3 of the moxa cake, and the bottom of the protrusion 1 The surrounding area is depressed 2 and lower than the upper surface 3 of the moxa cake. Inside the moxa cake, there is a blind hole 5 with the opening facing downward. The diameter of the blind hole 5 is 2mm. The bottom of the hole is flush with the upper surface 3 of the moxa cake, and the bottom surface 4 of the moxa cake 100 is an upwardly convex arc.

[0032] The present invention also provides a preparation process for the above-mentioned moxa cake correspondingly, comprising the following steps:

[0033] (1) get quantitative moxa and place the center in the cake-shaped mold that is provided with mandrel, and cake-shaped mold compri...

Embodiment 2

[0037] A moxa cake, pressed from moxa, with a density of 0.55g / cm 3 , see figure 1 , the moxa cake 100 is in the shape of a round cake as a whole, the diameter of the bottom surface is 20mm, and the height is 8mm; The lower depression 2 is lower than the upper surface 3 of the moxa cake. There is a blind hole 5 with the opening facing downward inside the moxa cake. The diameter of the blind hole 5 is 2.5mm. The bottom of the blind hole 5 is located in the protrusion. The height of the plane where the bottom is located is higher than the upper surface 3 of the moxa cake, and the bottom surface 4 of the moxa cake 100 is an upwardly convex arc.

[0038] The present invention also provides a preparation process for the above-mentioned moxa cake correspondingly, comprising the following steps:

[0039] (1) get quantitative moxa and place the center in the cake-shaped mold that is provided with mandrel, and cake-shaped mold comprises upper die and lower die, and the pressing surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com