Original-soil and in-situ slurrying-based underground wall construction method

A construction method and in-situ system technology, applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of lower project cost, rough walls, high requirements, etc., to improve project safety, reduce processing costs, enhance The effect of compressive properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

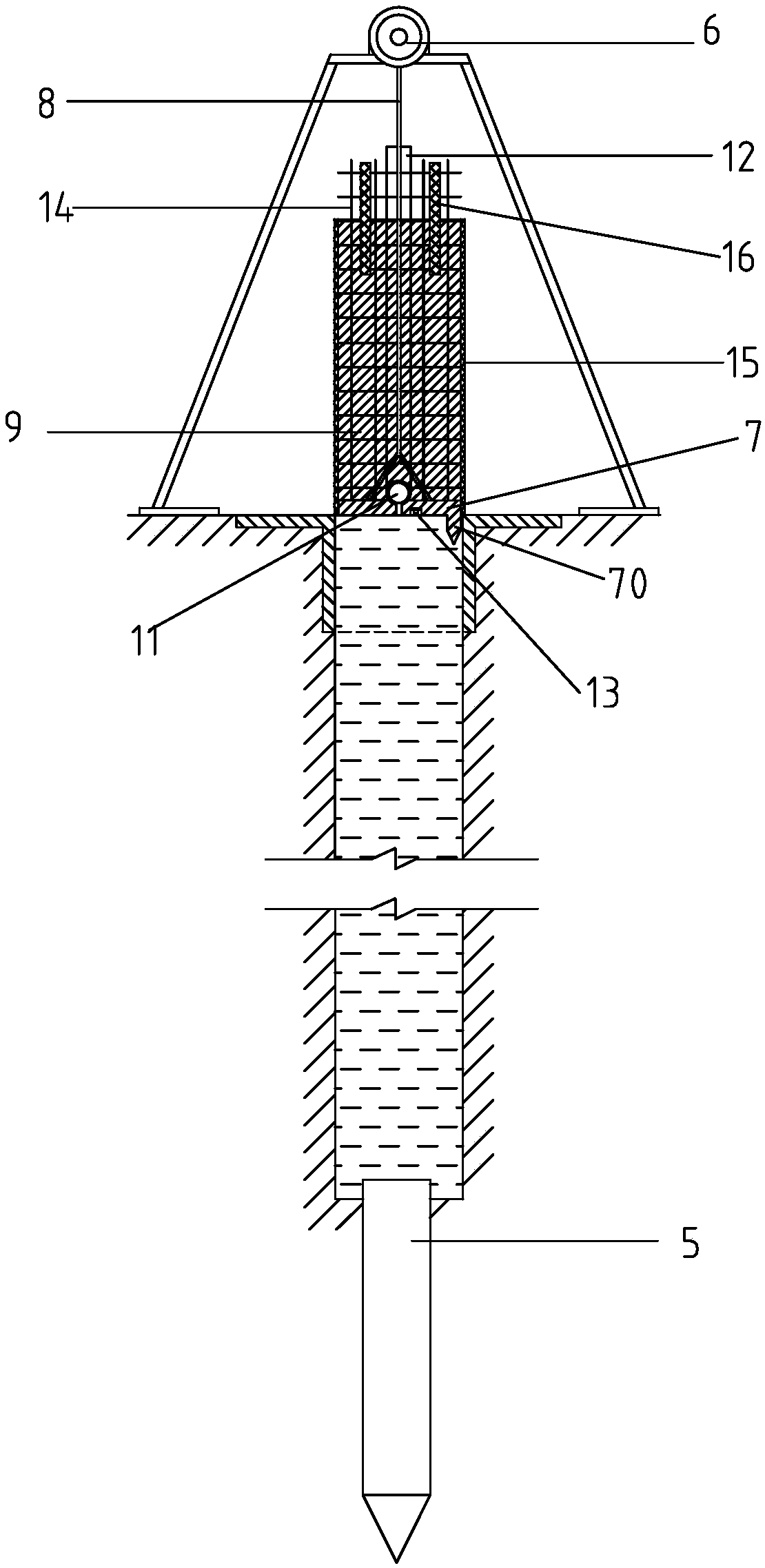

[0034] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5Shown is a kind of underground wall construction method based on original soil in-situ grouting, comprising the following steps: a, opening a back-shaped mud guide groove 1 with a depth of H1 on the ground, pouring guide wall 2 with concrete, Install the guide wall on both sides of the mud guide groove, open a groove 3 at the bottom of the guide groove through a slotting machine, and open a groove with a predetermined depth H in a back-shaped structure. The depth H1 of the guide groove is the same as the predetermined depth H The ratio is 0.07-0.15, and a plurality of parallel support beam avoidance grooves 4 are opened inside the groove, and the two ends of the support beam avoidance grooves communicate with the inner wall of the groove; b. The pipeline injects water into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com