Device for precisely adjusting steel supporting pre-exerted axial force of foundation pit and loading method thereof

A steel support and foundation pit technology, which is applied in excavation, infrastructure engineering, construction, etc., can solve problems such as effective stability, low construction efficiency of adjustment devices, and inability to pre-add axial force for precise adjustment, so as to avoid failure and improve construction efficiency. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

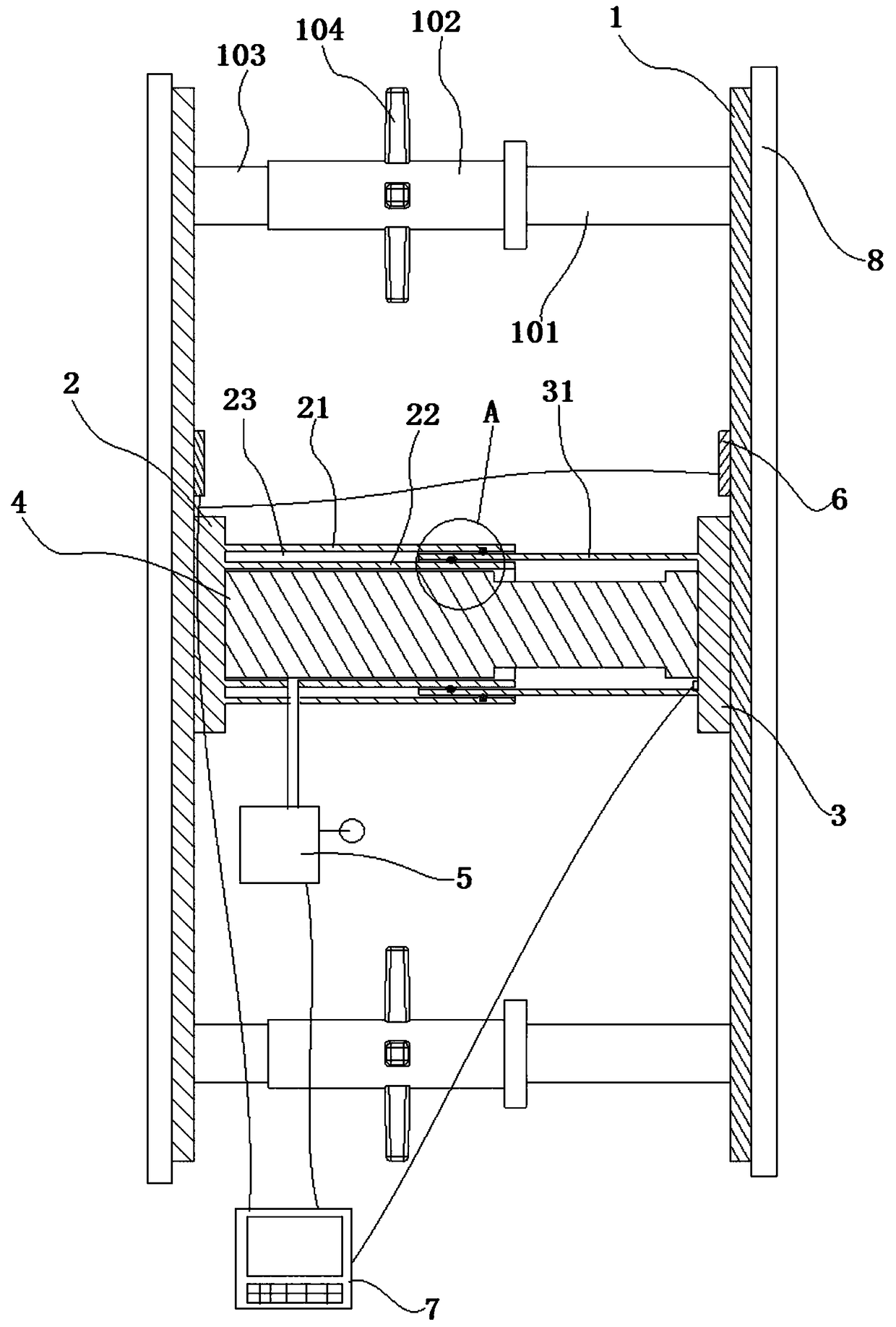

[0022] figure 1 It shows: a device for accurately adjusting the pre-loaded axial force of the foundation pit steel support, which is characterized in that it includes a fixed steel plate 1, a left loading slot 2, a right loading slot 3, a hydraulic jack 4, a hydraulic pump 5, a force sensor 6, a displacement Sensor, control panel 7 and auxiliary positioning device; the fixed steel plate 1 is provided with two pieces and is respectively fixed on the connecting beam 8 on both sides by bolts, and the fixed steel plate 1 is provided with a load cell 6; the left loading groove 2 One end is fixed on the fixed steel plate 1 on one side, the other end is composed of an outer cylinder 21 and an inner cylinder 22, the hydraulic jack 4 is fixed inside the inner cylinder 22, and an accommodation chamber 23 is formed between the inner wall of the outer cylinder 21 and the outer wall of the inner cylinder 22; One end of the right loading tank 3 is fixed on the fixed steel plate 1 on the oth...

Embodiment 2

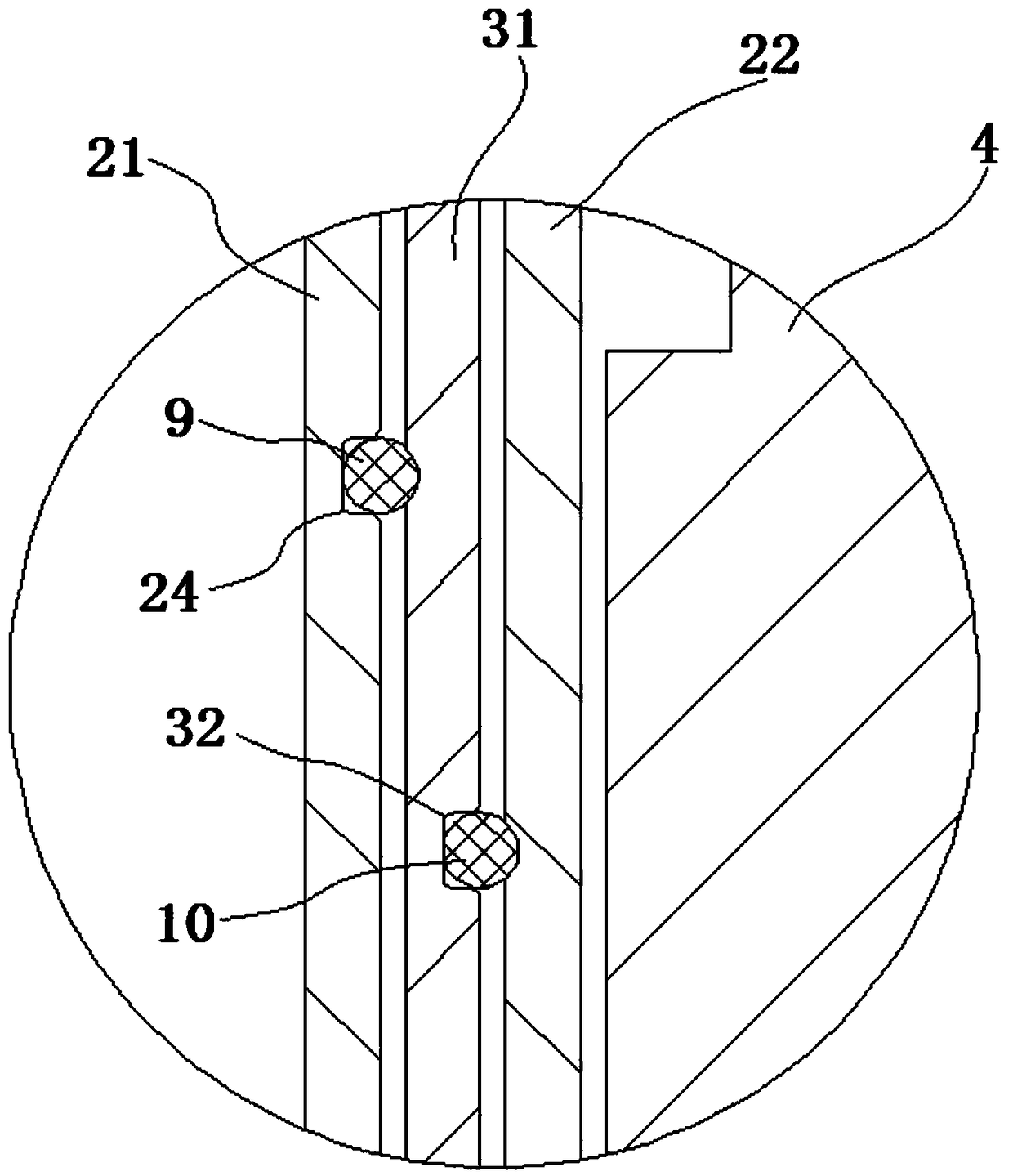

[0026] In order to further optimize the technical solution in Example 1, the inner wall of the cylinder 31 described in this example is concaved inward to form a first groove 32, and the first rubber ring 10 is clamped in the first groove 32, The inner diameter of the first rubber ring 10 is adapted to the outer diameter of the inner cylinder 22; the inner wall of the outer cylinder 21 is concaved to form a second groove 24, and the second rubber ring 9 is clamped in the second groove 24. The inner diameter of the rubber ring 9 is compatible with the outer diameter of the cylinder body 31 . Such as figure 2 As shown, the first rubber ring 10 is clamped between the cylinder body 31 and the inner cylinder 22, and the second rubber ring 9 is clamped between the cylinder body 31 and the outer cylinder 21 to limit the movement track of the cylinder body 31 and avoid the occurrence of diameters. direction displacement, while avoiding the direct contact between the cylinder body 31 a...

Embodiment 3

[0028] In order to further optimize the technical solution in Embodiment 1 or 2, the number of auxiliary positioning devices in this embodiment is 4 sets, which are respectively located on the four corners of the fixed steel plate 1 . The applied axial pressure is stabilized by 4 auxiliary positioning devices, making the support more stable and reliable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com