Energy dissipation structure capable of adjusting tail sill height of stilling basin and adjusting method thereof

A stilling pool and adjustable technology, which is applied in sea area engineering, construction, barrage/weir, etc., can solve the problems of the stability of the water flow in the stilling pool, the low energy dissipation efficiency of the stilling pool, the stability of the bottom plate of the stilling pool, etc. Achieve the effect of improving the atomization phenomenon, increasing the energy dissipation rate and weakening the impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

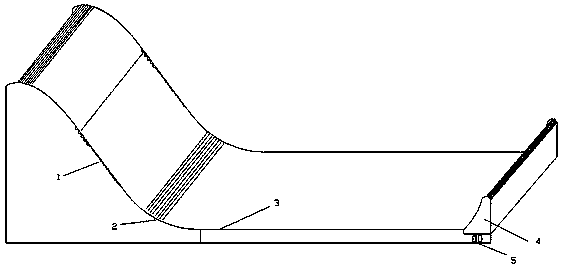

[0029] Embodiment 1: as figure 1 with 4 As shown, when the weir crest single width discharge is 180m 3 When the single-width flow rate is within the range of / s·m or even smaller, the hydraulic jacking device 5 is not adjusted, and the overall operation is carried out at the original height of the tail sill 4 of the stilling basin. In this case, the stability of the overall water flow in the stilling basin 3 is improved, and the hydrostatic pressure on the bottom plate of the stilling basin can be reduced to a certain extent, which is beneficial to the stability of the bottom plate of the stilling basin, and can make the water in the stilling basin The overall hydraulic characteristics are optimal, including energy dissipation rate, water surface fluctuation, water depth of stilling basin, flow velocity near the bottom of stilling basin, and hourly average pressure on the bottom of stilling basin, etc. The water in the pool flows downstream more smoothly; compared with the s...

Embodiment 2

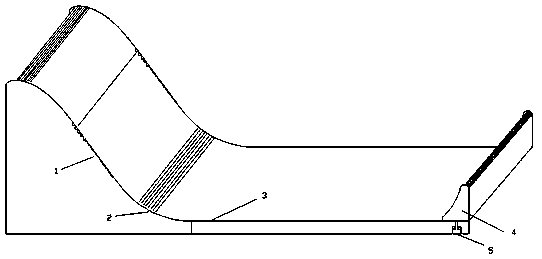

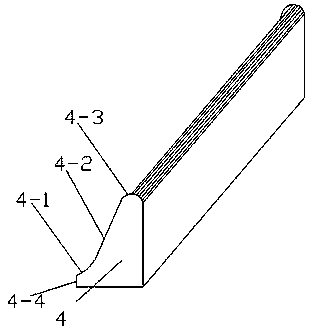

[0030] Embodiment 2: as figure 2 with 5 As shown, when the single-width flow rate of the water flow over the weir crest is 180m 3 / s·m and higher single-width flow rate, a certain degree of energy dissipation in the stilling basin is required, and the height H of the tail sill 4 of the stilling basin can be changed by the hydraulic jacking device 5 . The required height H is different under different flow rates. First, when the height H of the tail sill 4 of the stilling basin needs to be increased, the volume V of the main hydraulic cylinder 5-2 can be reduced by the main hydraulic pump 5-1, and by Adjust the opening of the main hydraulic valve 5-3 to control the liquid flow Q in the hydraulic main pipeline 5-4, so that the rising speed of the tail sill 4 of the stilling pool will not be too fast. When the volume V of the main hydraulic cylinder 5-2 decreases When the volume v of the auxiliary hydraulic cylinder 5-5 increases, the auxiliary jacking column 5-6 is forced to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com