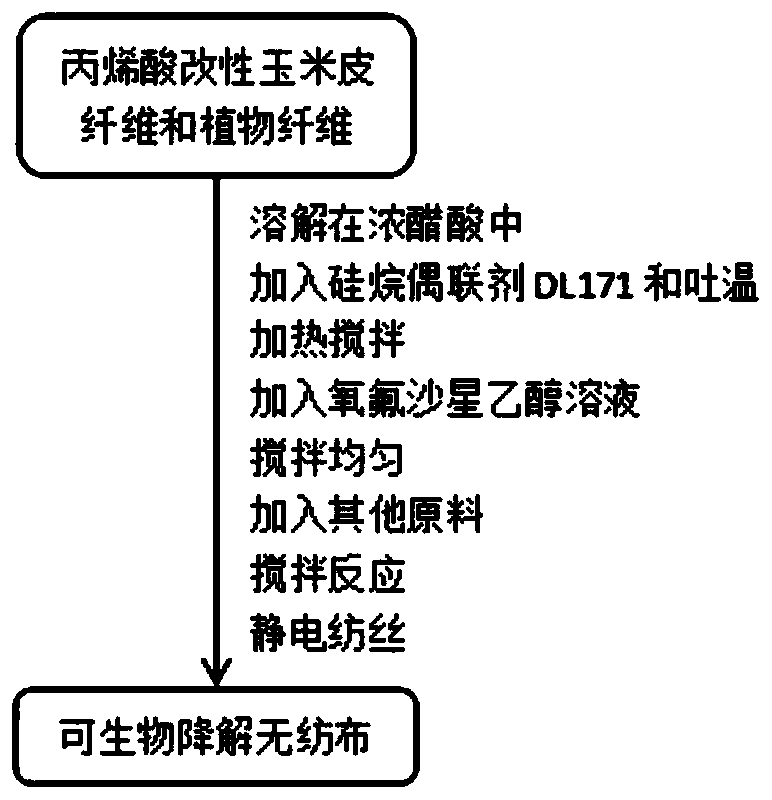

A kind of biodegradable non-woven fabric and preparation method thereof

A biodegradable, non-woven technology, used in electrospinning, non-woven fabrics, textiles and papermaking, etc., can solve problems such as spinning difficulties, achieve good mechanical properties and fresh-keeping properties, reduce costs, and have a wide range of effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The preparation of embodiment 1 biodegradable non-woven fabric

[0060] Raw material composition:

[0061] 70 parts of acrylic acid modified corn bran fiber;

[0062] 30 parts of abaca leaves;

[0063] 20 parts of ofloxacin;

[0064] Silane coupling agent DL1715 parts;

[0065] Tween 5 parts;

[0066] 1 part of 2,2'-thiobis(4-tert-octylphenoxy)nickel;

[0067] 1 part of resorcinol monobenzoate;

[0068] Polysorbate 801 parts;

[0069] 5 parts of decabromo-antimony trioxide;

[0070] 5 parts of tetrakis [β-(3,5-tertiary butyl-4-hydroxyphenyl) propionate] pentaerythritol ester;

[0071] 5 parts of diethyl phthalate.

[0072] Preparation of acrylic acid modified corn husk fiber: Wash the corn husk fiber, dry it in the sun, heat and dissolve it in a mixed solvent of toluene and n-butanol (4:1 by volume), add n-dodecanethiol, remove oxygen for 30 minutes, Introduce argon, continue to add methyl methacrylate, ethyl acrylate, butyl acrylate and acrylonitrile monomers...

Embodiment 2

[0074] The preparation of embodiment 2 biodegradable non-woven fabrics

[0075] Raw material composition:

[0076] 100 parts of acrylic acid modified corn bran fiber;

[0077] 50 parts of willow seed hair;

[0078] 30 parts of ofloxacin;

[0079] Silane coupling agent DL17115 parts;

[0080] Tween 10 parts;

[0081] 5 parts of 2,2'-thiobis(4-tert-octylphenoxy)nickel;

[0082] 5 parts of resorcinol monobenzoate;

[0083] Polysorbate 8010 parts;

[0084] 10 parts of hexabromocyclododecane;

[0085] 15 parts of three (dodecyl alcohol) esters;

[0086] 10 parts of diisodecyl phthalate.

[0087] Preparation of acrylic acid modified corn husk fiber: Wash the corn husk fiber, dry it in the sun, heat and dissolve it in a mixed solvent of toluene and n-butanol (4:1 by volume), add n-dodecanethiol, remove oxygen for 30 minutes, Introduce argon, continue to add methyl methacrylate, ethyl acrylate, butyl acrylate and acrylonitrile monomers, under the trigger of the initiator azo...

Embodiment 3

[0089] The preparation of embodiment 3 biodegradable non-woven fabrics

[0090] Raw material composition:

[0091] 80 parts of acrylic acid modified corn bran fiber;

[0092] 45 parts jute stalks;

[0093] Ofloxacin 27 parts;

[0094] Silane coupling agent DL17112 parts;

[0095] Tween 8 parts;

[0096] 4 parts of 2,2'-thiobis(4-tert-octylphenoxy)nickel;

[0097] 4 parts of resorcinol monobenzoate;

[0098] Polysorbate 808 parts;

[0099] 8 parts of flame retardant MCA;

[0100] 12 parts of diphenylamine;

[0101] 9 parts of butyl benzyl phthalate.

[0102] Preparation of acrylic acid modified corn husk fiber: Wash the corn husk fiber, dry it in the sun, heat and dissolve it in a mixed solvent of toluene and n-butanol (4:1 by volume), add n-dodecanethiol, remove oxygen for 30 minutes, Introduce argon, continue to add methyl methacrylate, ethyl acrylate, butyl acrylate and acrylonitrile monomers, under the trigger of the initiator azobisisobutyronitrile, heat to 90 ° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com