Green efficient electrochemical preparation method of high-quality water-soluble graphene

A water-soluble, graphene technology, applied in the direction of graphene, nano-carbon, etc., can solve the problems of weak oxidation efficiency and insolubility of the electrolyte, achieve a wide range of industrial application prospects, short process time, and overcome the effects of poor water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

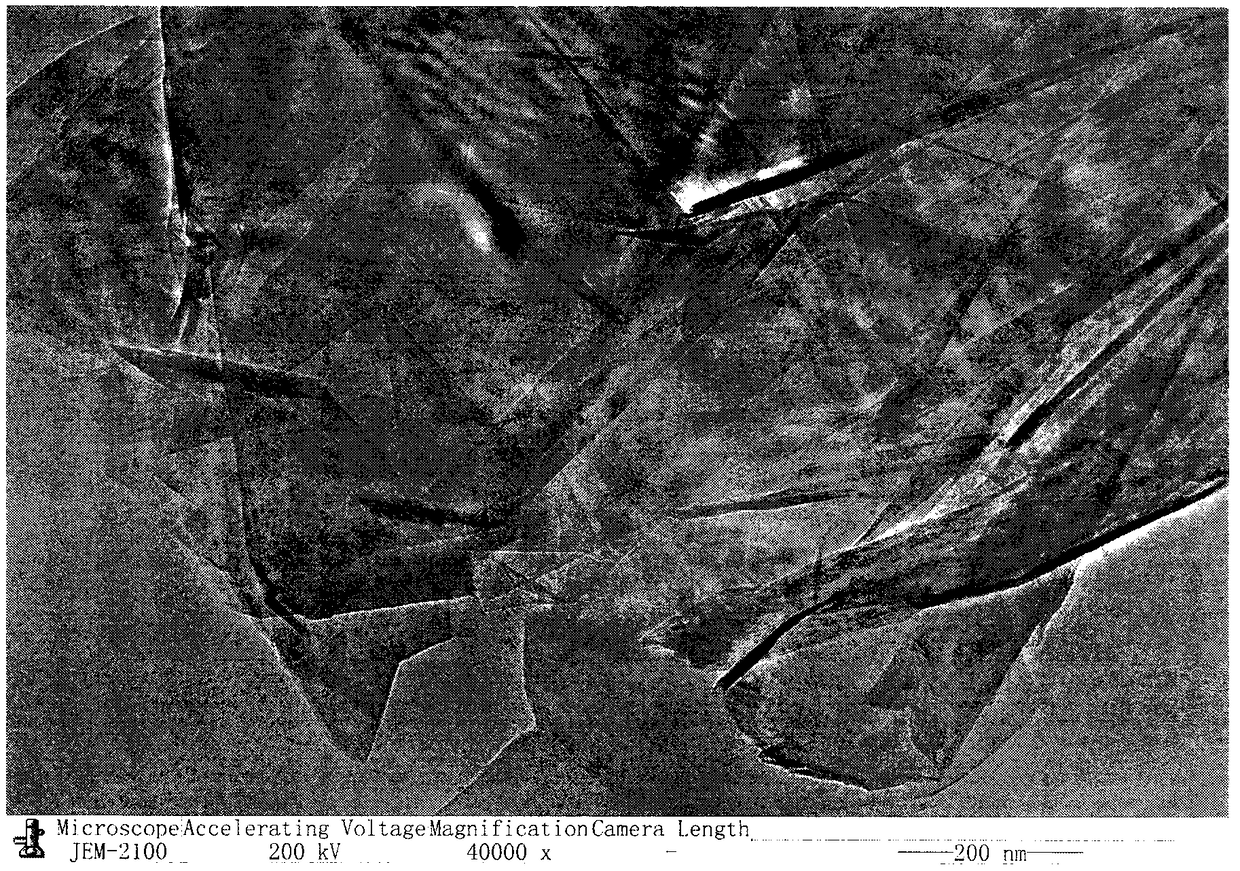

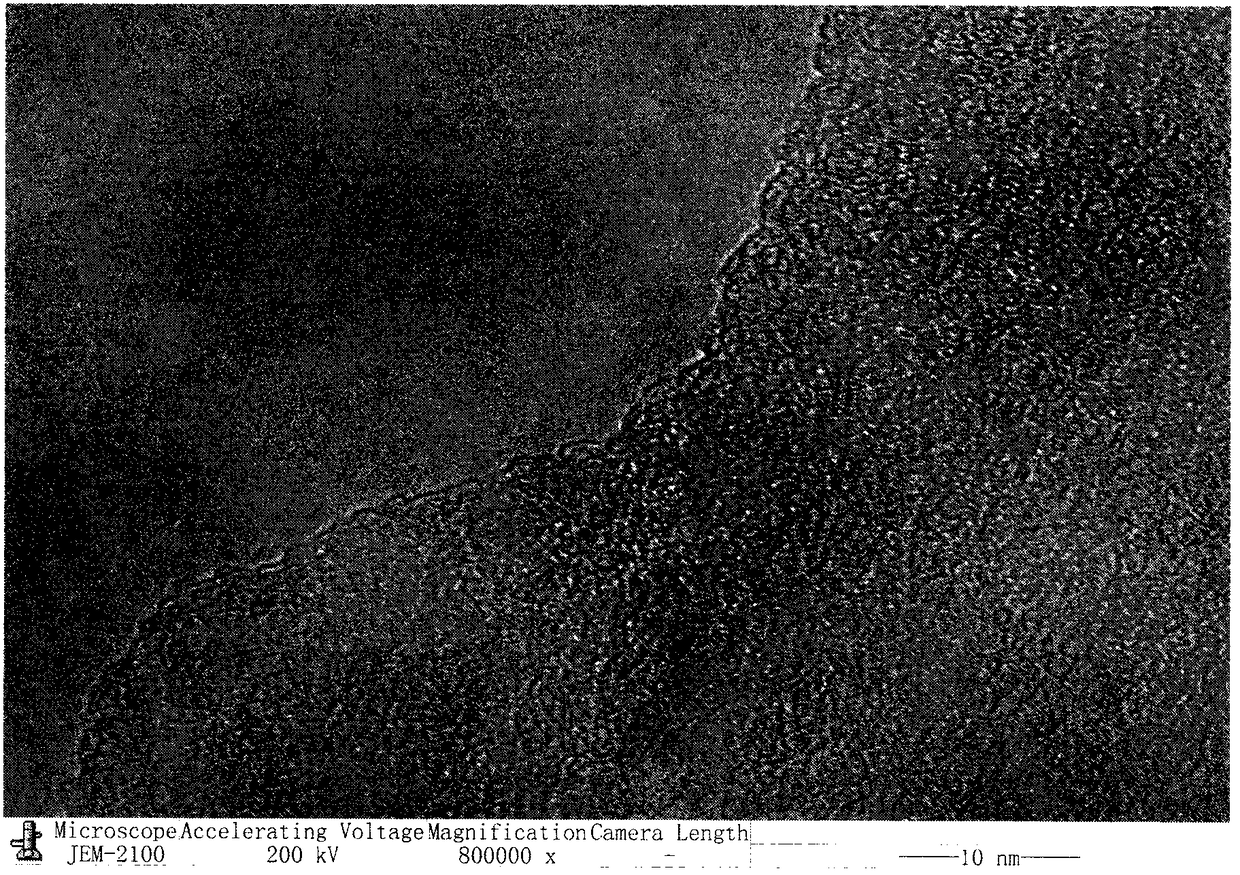

Image

Examples

Embodiment 1

[0033] This embodiment adopts the following steps in order to prepare high-quality water-soluble graphene.

[0034] a) Build a device for preparing water-soluble graphene:

[0035] Dissolve 13.8g of salicylic acid and 16.0g of sodium hydroxide in 1000mL of deionized water and put it in a 2000mL beaker to be the electrolyte; Dilute 10*10*0.3cm 3 Graphite foil as anode, 10*20*0.1cm 3 The platinum sheet is used as the cathode, and the two electrodes are vertically and parallelly placed in the electrolyte, the distance between the two electrodes is 3cm, and the two electrodes are respectively connected to the positive and negative poles of the DC power supply with wires;

[0036] b) peel off the graphite foil to prepare water-soluble graphene:

[0037] The voltage of the power supply is set to 10V, and the electrolytic reaction is carried out to electrochemically peel off the graphite foil; in the electrolytic reaction, accompanied by magnetic sub-stirring, the rotational speed ...

Embodiment 2

[0044] This embodiment adopts the following steps in order to prepare high-quality water-soluble graphene.

[0045] a) Build a device for preparing water-soluble graphene:

[0046] Dissolve 16.6g of terephthalic acid and 16.0g of sodium hydroxide in 1000mL of deionized water, and place it in a 2000mL beaker to form the electrolyte; 10*10*0.3cm 3 Graphite foil as anode, 10*20*0.1cm 3 The platinum sheet is used as the cathode, and the two electrodes are vertically and parallelly placed in the electrolyte, the distance between the two electrodes is 3cm, and the two electrodes are respectively connected to the positive and negative poles of the DC power supply with wires;

[0047] b) peel off the graphite foil to prepare water-soluble graphene:

[0048] The voltage of the power supply is set to 10V, and the electrolytic reaction is carried out to electrochemically peel off the graphite foil; in the electrolytic reaction, accompanied by magnetic sub-stirring, the rotational speed...

Embodiment 3

[0055] This embodiment adopts the following steps in order to prepare high-quality water-soluble graphene.

[0056] a) Build a device for preparing water-soluble graphene:

[0057] Dissolve 12.2g of benzoic acid and 8.0g of sodium hydroxide in 1000mL of deionized water and place it in a 2000mL beaker to form the electrolyte; 3 Graphite foil as anode, 10*20*0.1cm 3 The platinum sheet is used as the cathode, and the two electrodes are vertically and parallelly placed in the electrolyte, the distance between the two electrodes is 3cm, and the two electrodes are respectively connected to the positive and negative poles of the DC power supply with wires;

[0058] b) peel off the graphite foil to prepare water-soluble graphene:

[0059] The voltage of the power supply is set to 12V, and the electrolytic reaction is carried out to electrochemically peel off the graphite foil; in the electrolytic reaction, accompanied by magnetic sub-stirring, the rotational speed of the magnetic su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com