Lifting appliance for loading and unloading special vehicle balance elbow

A technology for special vehicles and balance elbows is applied in the field of slings for loading and unloading balance elbows of special vehicles. , reduce the effect of the main arm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to better understand the present invention, the technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

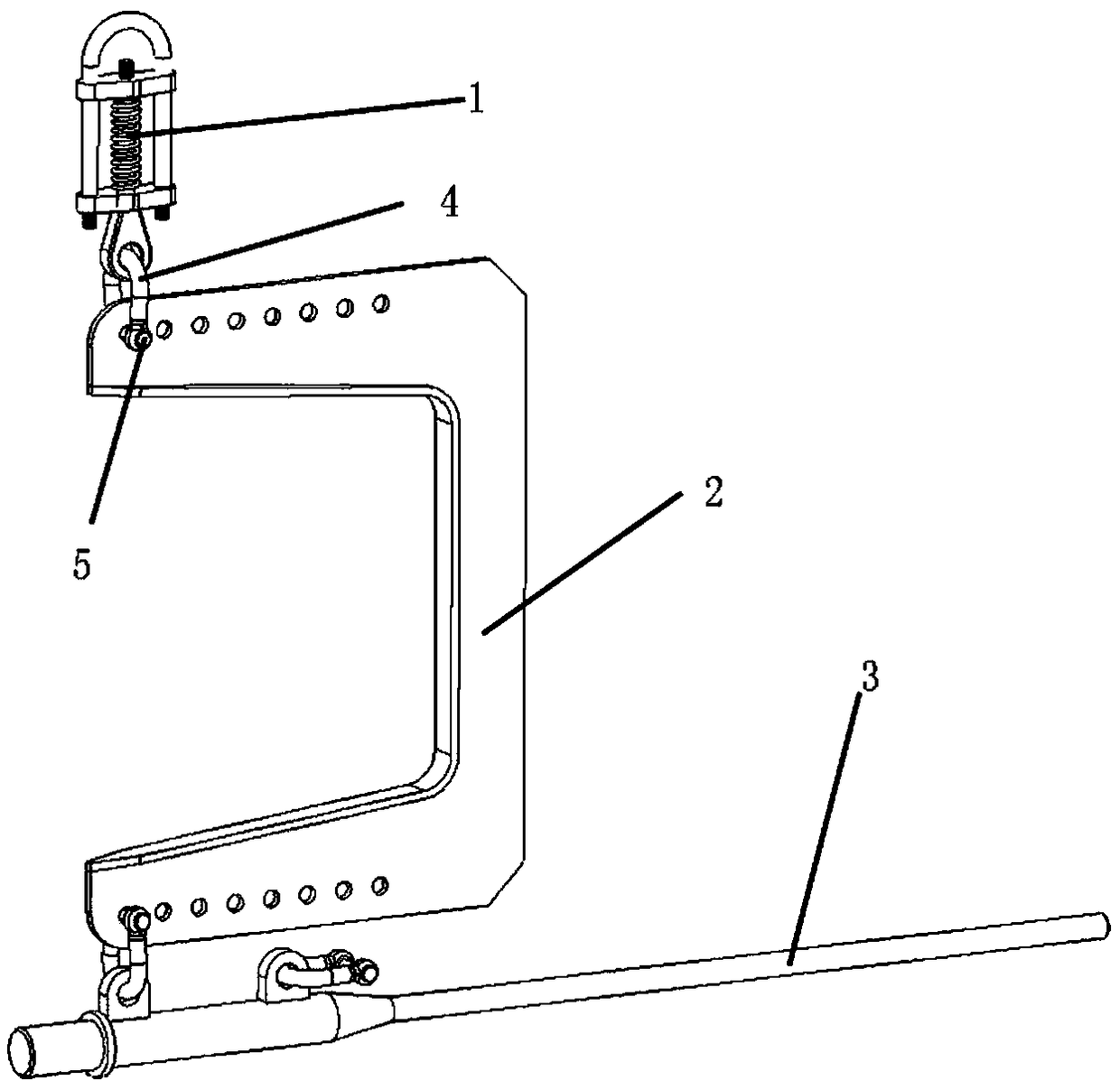

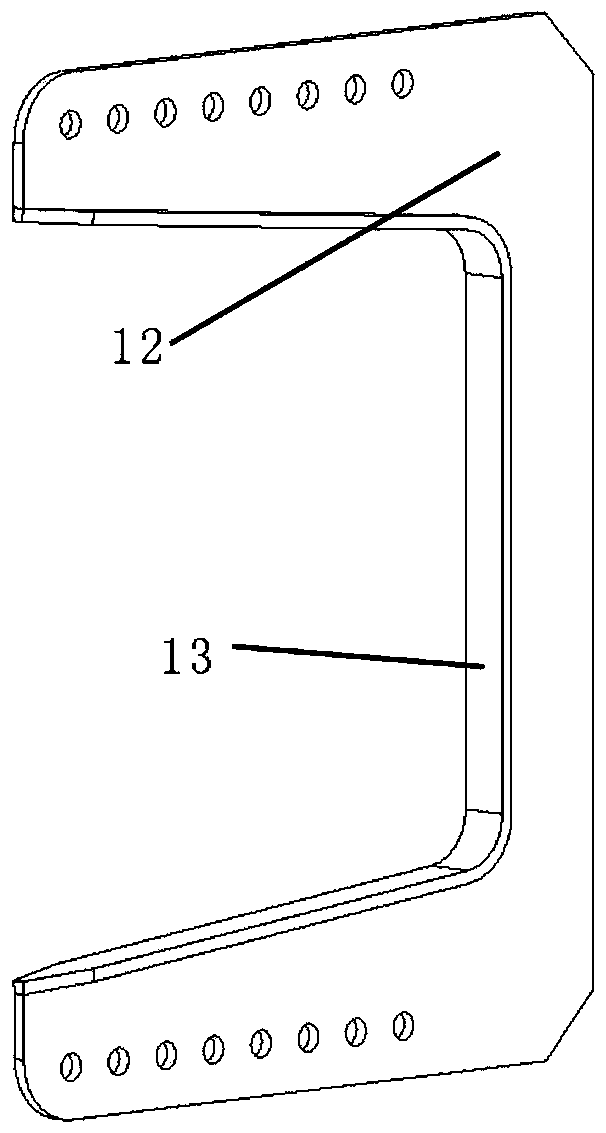

[0037] Such as Figure 1 to Figure 4 As shown, this embodiment provides a spreader for loading and unloading special vehicle balance elbows, including a compensator 1 that can compensate for in-position deviation, a C-shaped frame 2 that shortens the resistance arm on one side of the vehicle balance elbow, and a balance crowbar 3;

[0038] The C-shaped frame 2 is respectively connected with the compensator 1 and the balance crowbar 3 through a connecting ring 4;

[0039] The spreader is connected with the lifting equipment through the compensator 1 .

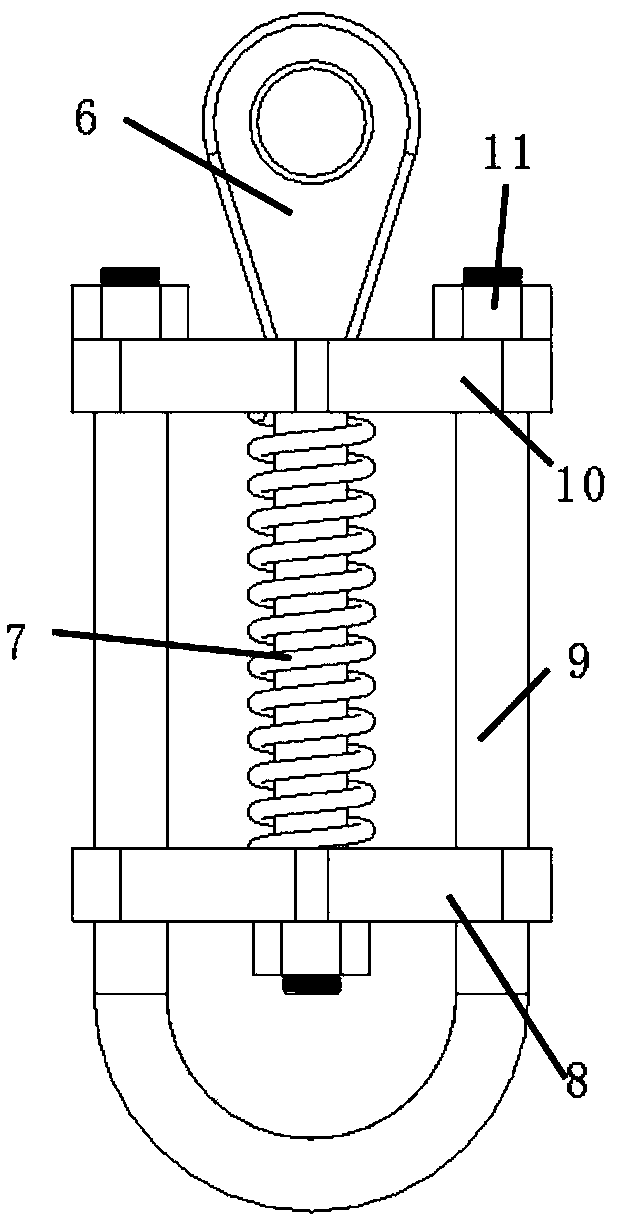

[0040] Preferably, the compensator 1 includes: a U-shaped lifting ring 9 arranged vertically, a fixing plate 10 and a sliding plate 8 respectively arranged transversely on the U-shaped lifting ring 9, passing through the fixing plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com