Cell pole piece tension swing arm mechanism and swing arm tension control method

A tension and pole piece technology, applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of reducing battery safety performance, affecting the quality of battery cores, shortening battery life, etc. The effect of high precision, reasonable force and prolonging battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

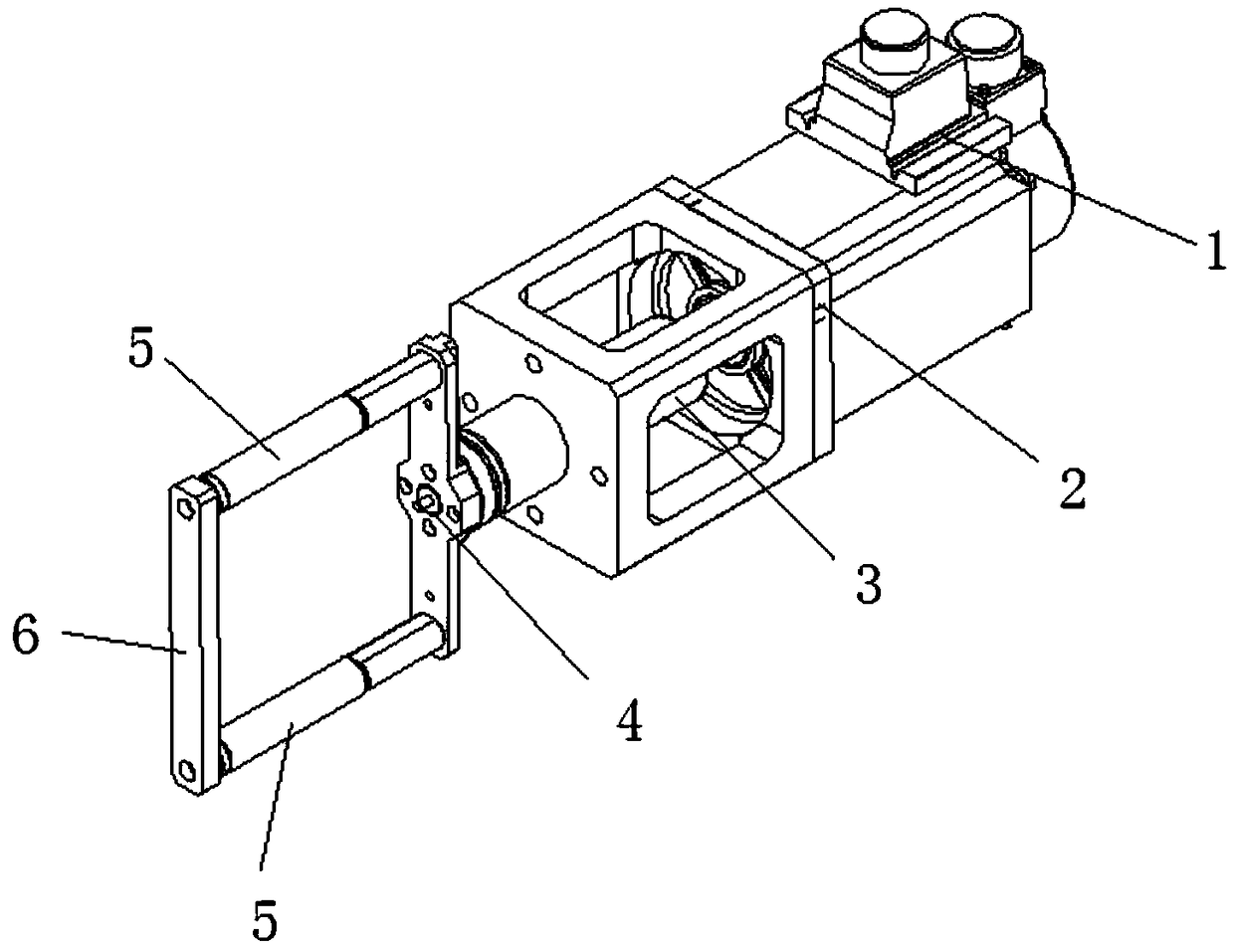

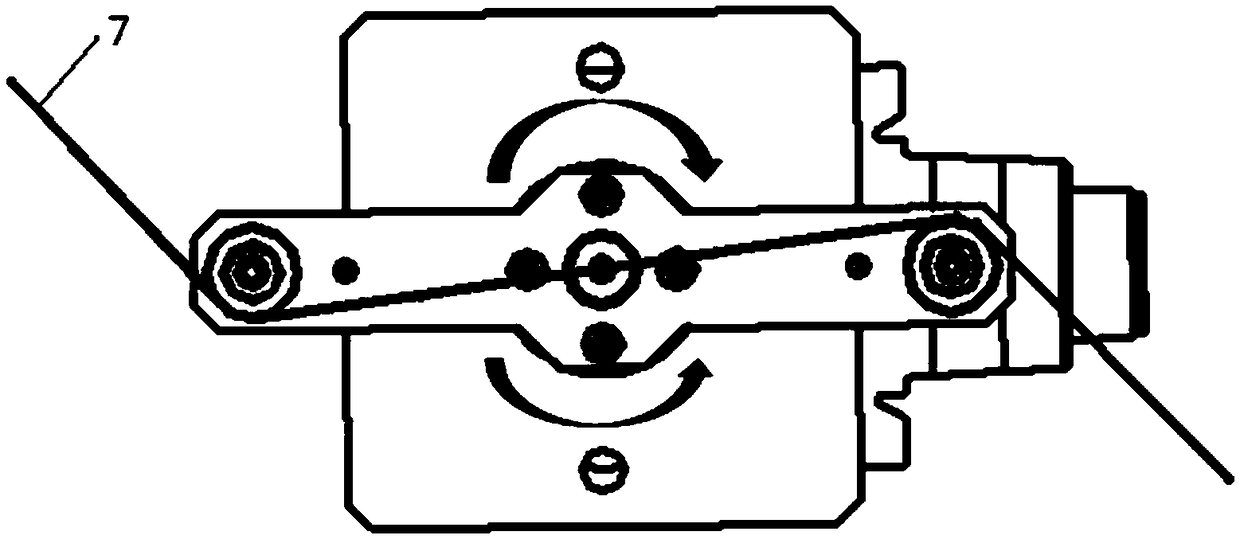

[0023] Examples, see attached Figure 1~2 , a battery pole piece tension swing arm mechanism, including a servo motor 1, the servo motor is installed on the motor base 2, the main shaft of the servo motor is connected with the tension swing arm 4 through a coupling 3, and the tension swing arm It includes a driving arm and two sets of roller shafts vertically installed on the driving arm, and one end of the roller shaft has a large diameter, and the other end of the roller shaft has a small diameter, and the pole piece passing roller is installed at the small diameter end of the roller shaft.

[0024] Two groups of pole piece passing rollers 5 are symmetrically installed on the tension swing arm, and the pole piece passing rollers are cylindrical roller structures, and the ends of the two groups of pole piece passing rollers are connected by a roller connecting plate 6, and the passing roller connecting plate It is a long strip, and the pole piece is taken between two sets of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com