Belt conveyor suitable for automobile welding production line

A welding production line and belt conveyor technology, applied in conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of high personnel quota, low production efficiency, time occupied, etc., to achieve low cost and improve production efficiency. , the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

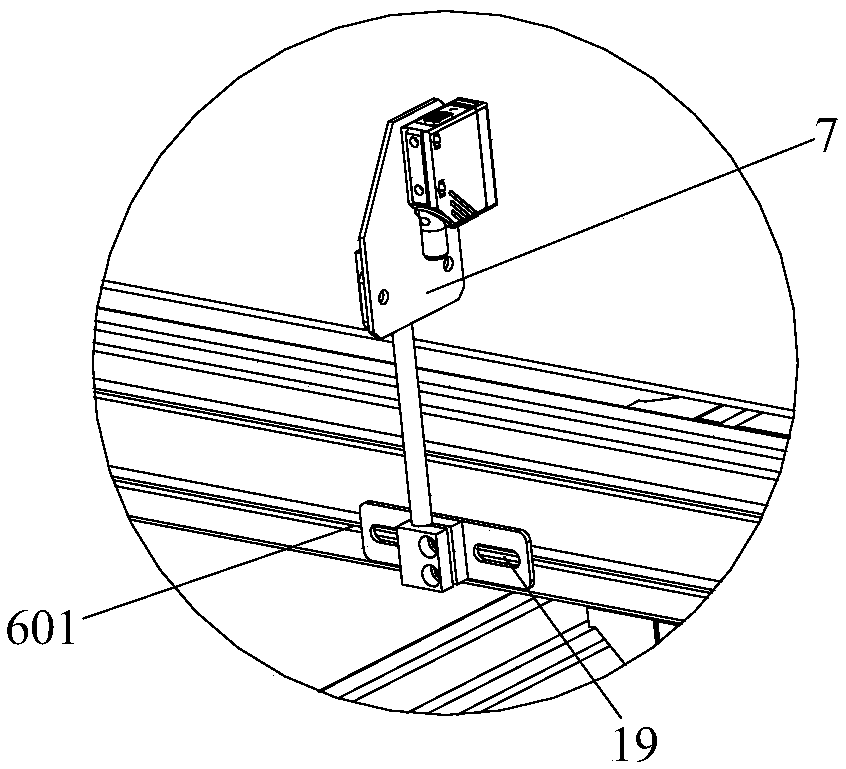

[0023] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

[0024] It should be noted that in the following embodiments, the "first", "second", "third", "fourth", "fifth" and "sixth" do not represent structures and / or Or absolute distinctions in function, but for convenience of description only.

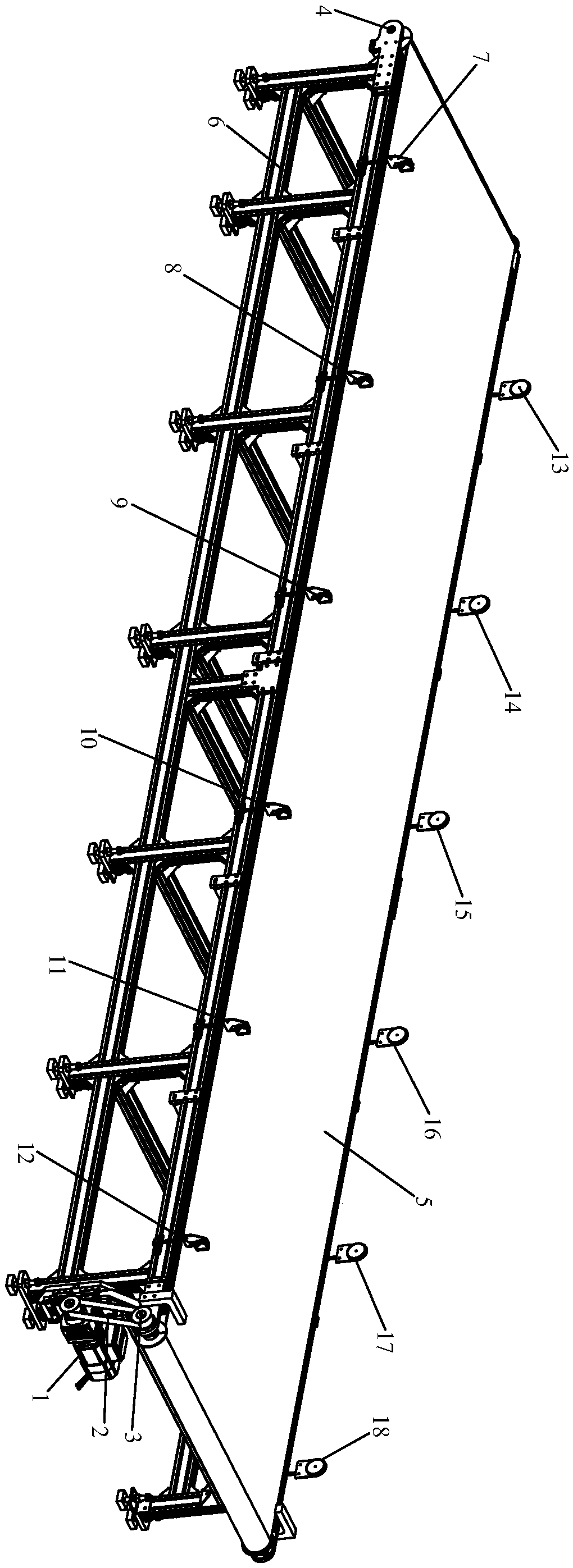

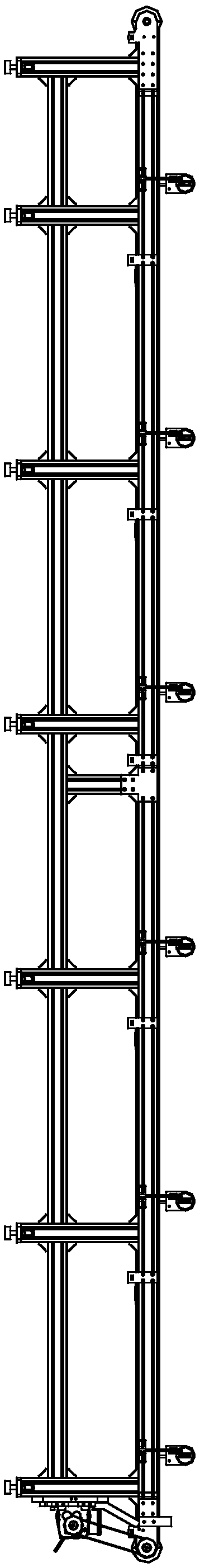

[0025] Such as figure 1 and figure 2 As shown, the present invention provides a kind of belt conveyor suitable for automobile welding production line, comprises frame 6, drive shaft 3, driven shaft 4, conveyer belt 5, driving device and control device, and conveyer belt 5 is provided with a feeding position and n storage positions, all n storage positions are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com