Collector assembly packaging whole line

A collector and packaging line technology, which is used in transportation and packaging, conveyor control devices, conveyor objects, etc., can solve the problems of cumbersome assembling steps of data collectors, difficult to improve efficiency, affecting production efficiency, etc. The effect of scrapping, improving precision, and reducing process sequence dependencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

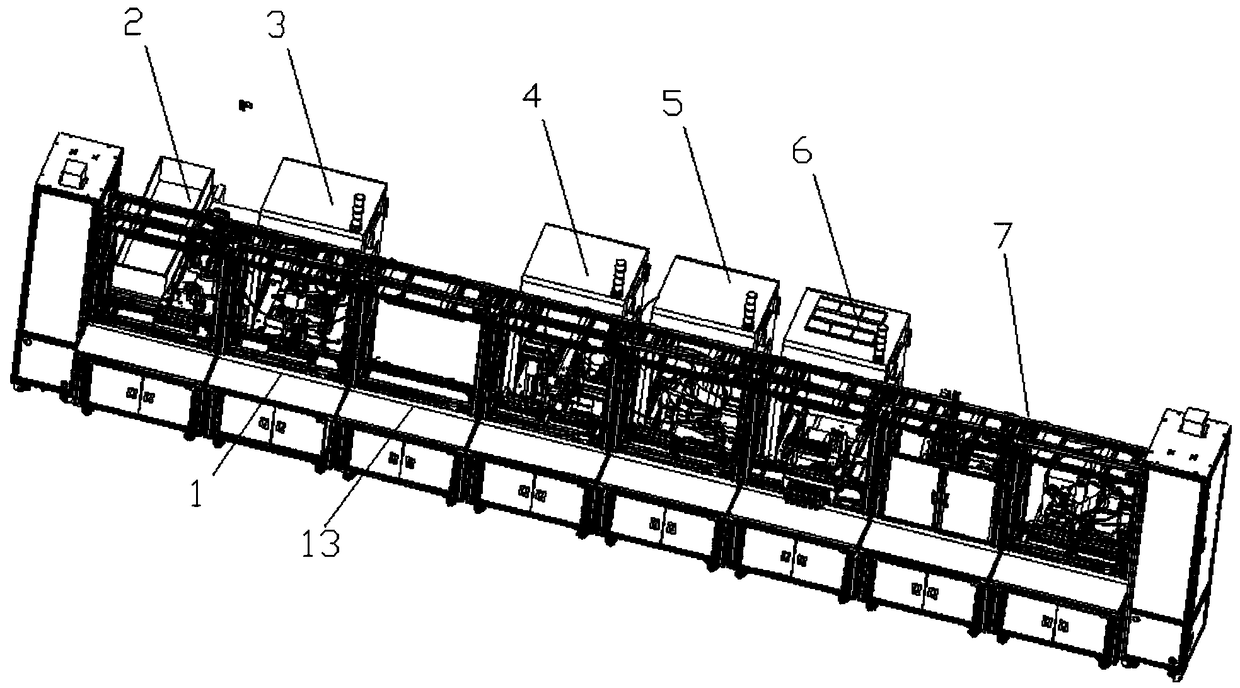

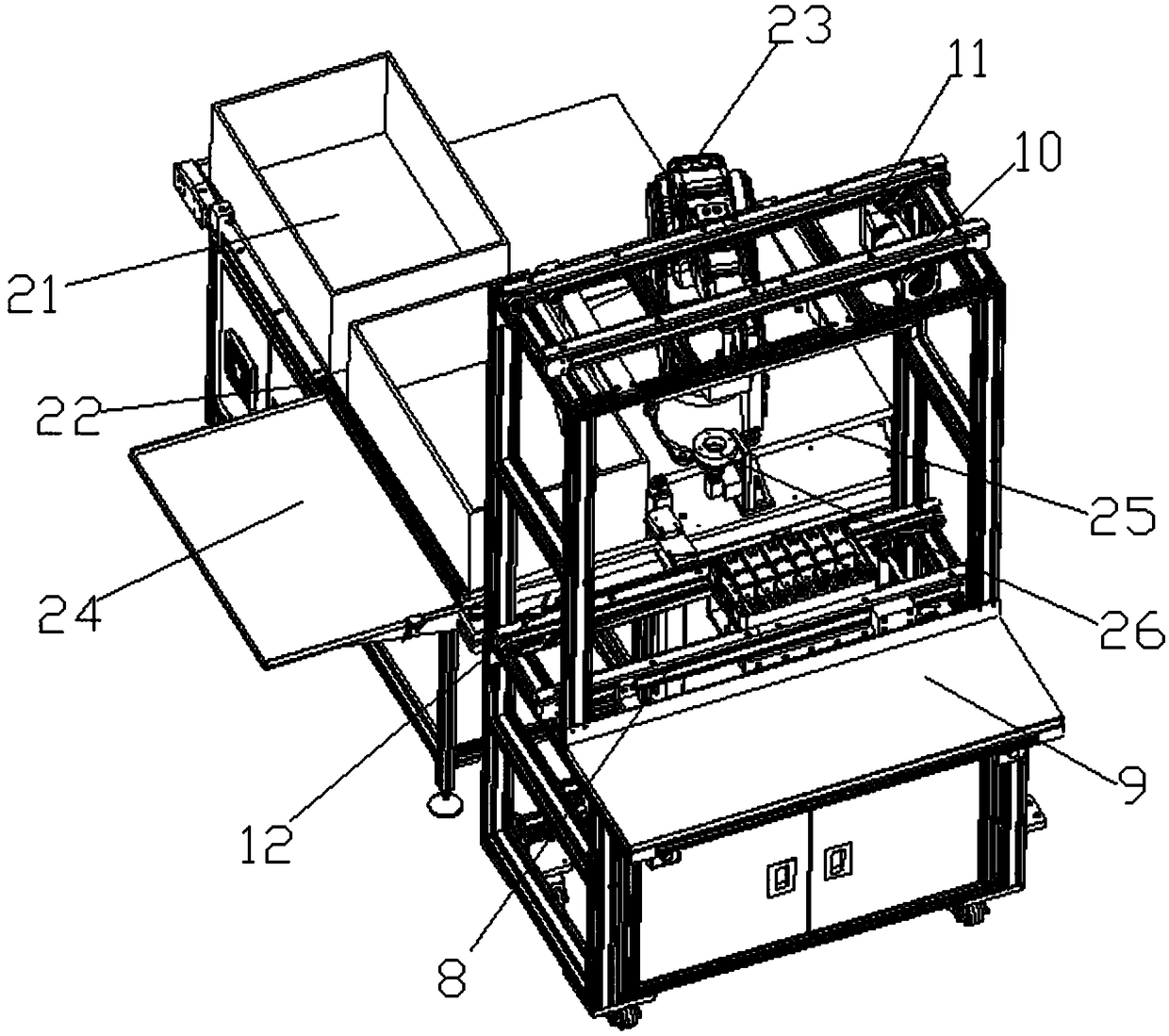

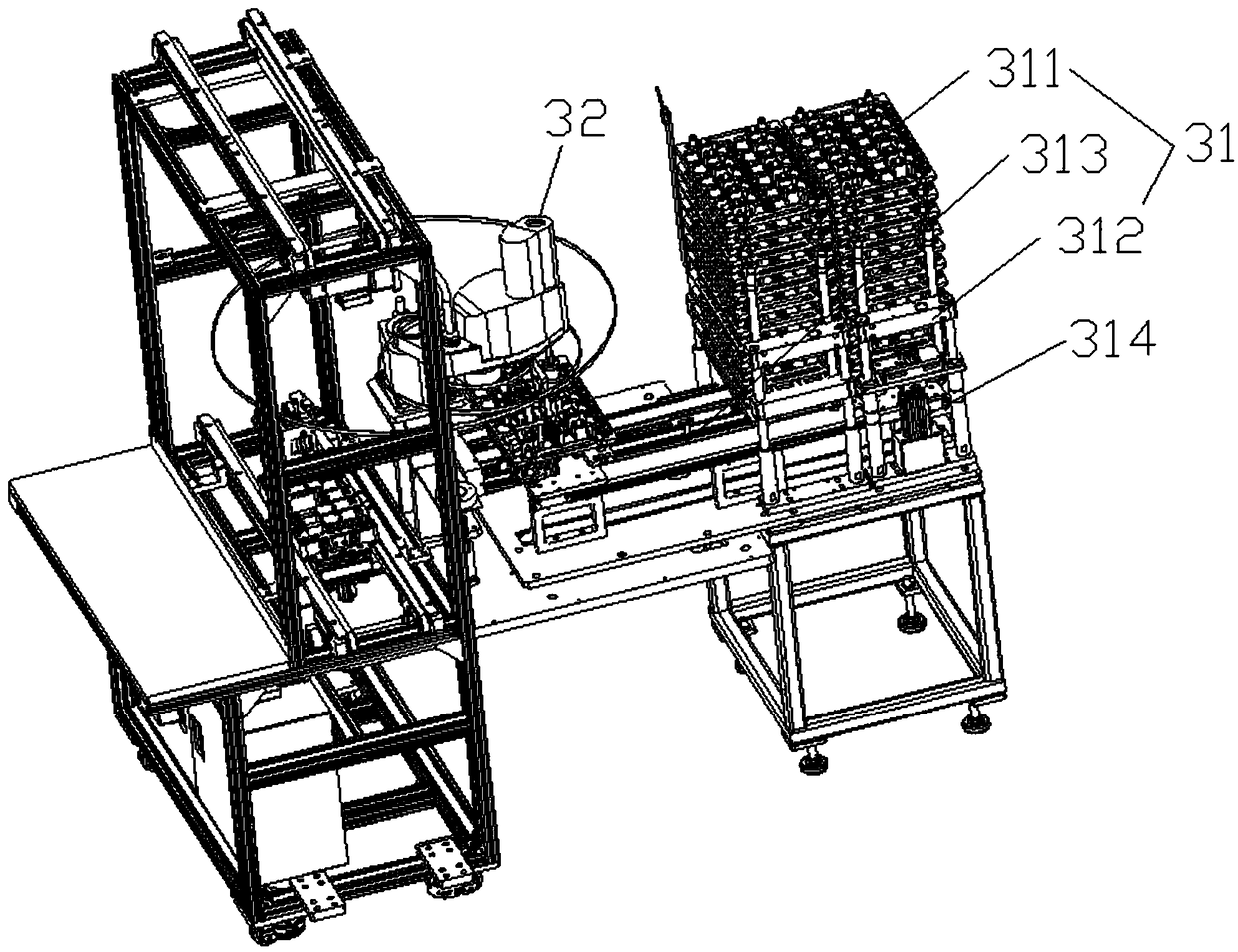

[0022] Such as figure 1 and image 3 As shown, the collector assembly and packaging line includes the shell automatic feeding mechanism 2, the PCB board placement mechanism 3, the automatic locking screw mechanism 4, the automatic cover closure mechanism 5, and the function for detecting whether the collector is qualified. Testing mechanism 6 and labeling mechanism 7. The collector housing is placed on the carrier of the mobile operation line 8, an RFID card is placed under the carrier, and an RFID card for scanning, reading and writing data to the collector in each carrier is installed under each mobile operation line 8. industrial card reader. Described PCB board placing mechanism 3 comprises PCB board sub-disk feeding mechanism 31 and is arranged on the PCB board sub-disc feeding mechanism 31 side for grabbing and placing the PCB board fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com