A high-efficiency automatic film tearing machine

A plate-setting machine and automatic technology, which is applied to home appliances, other home appliances, and household components, etc., can solve the problems of difficult control of enterprise production efficiency, high labor intensity of employees, and high labor costs, so as to avoid human error and reduce High labor intensity and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

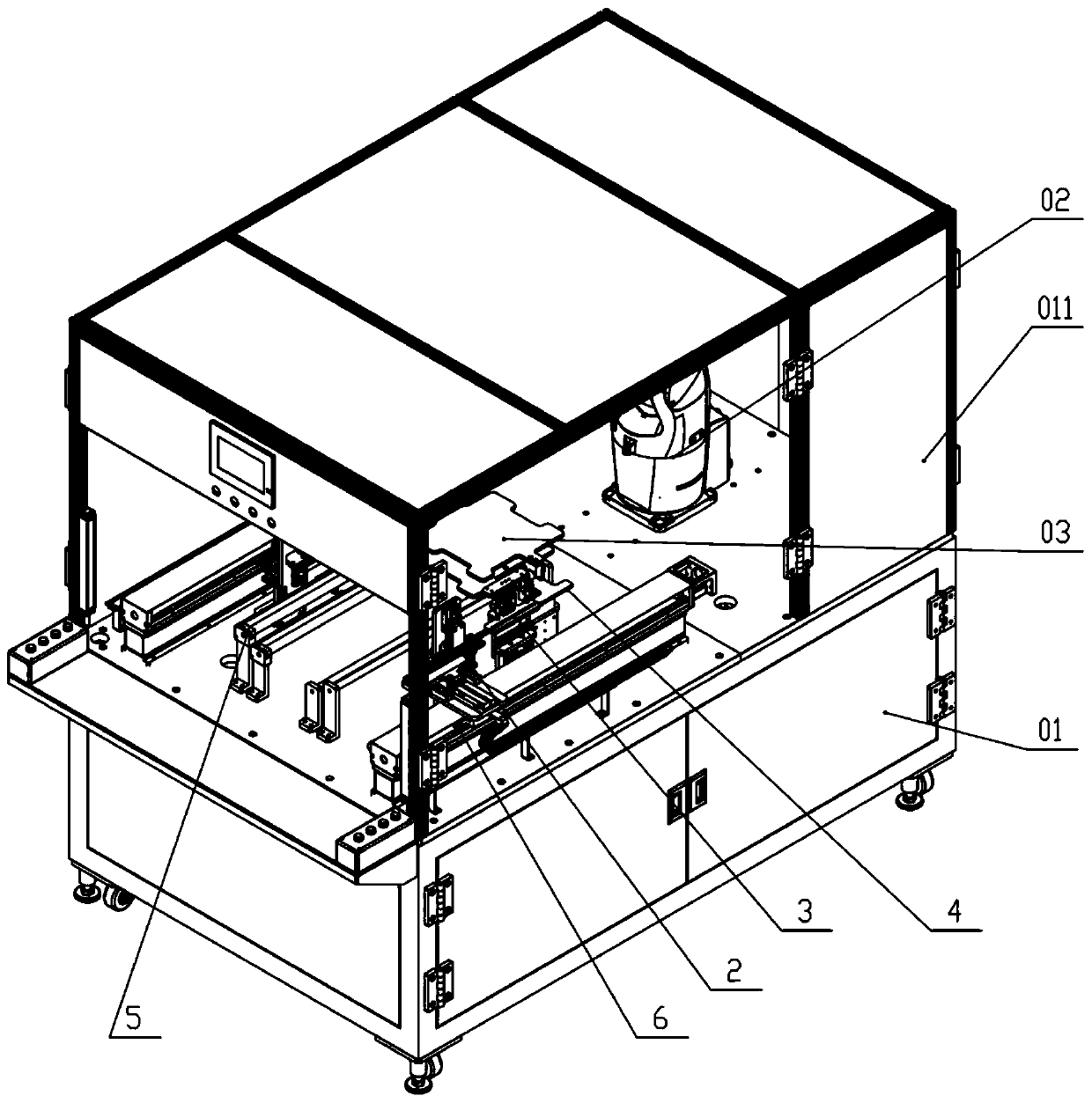

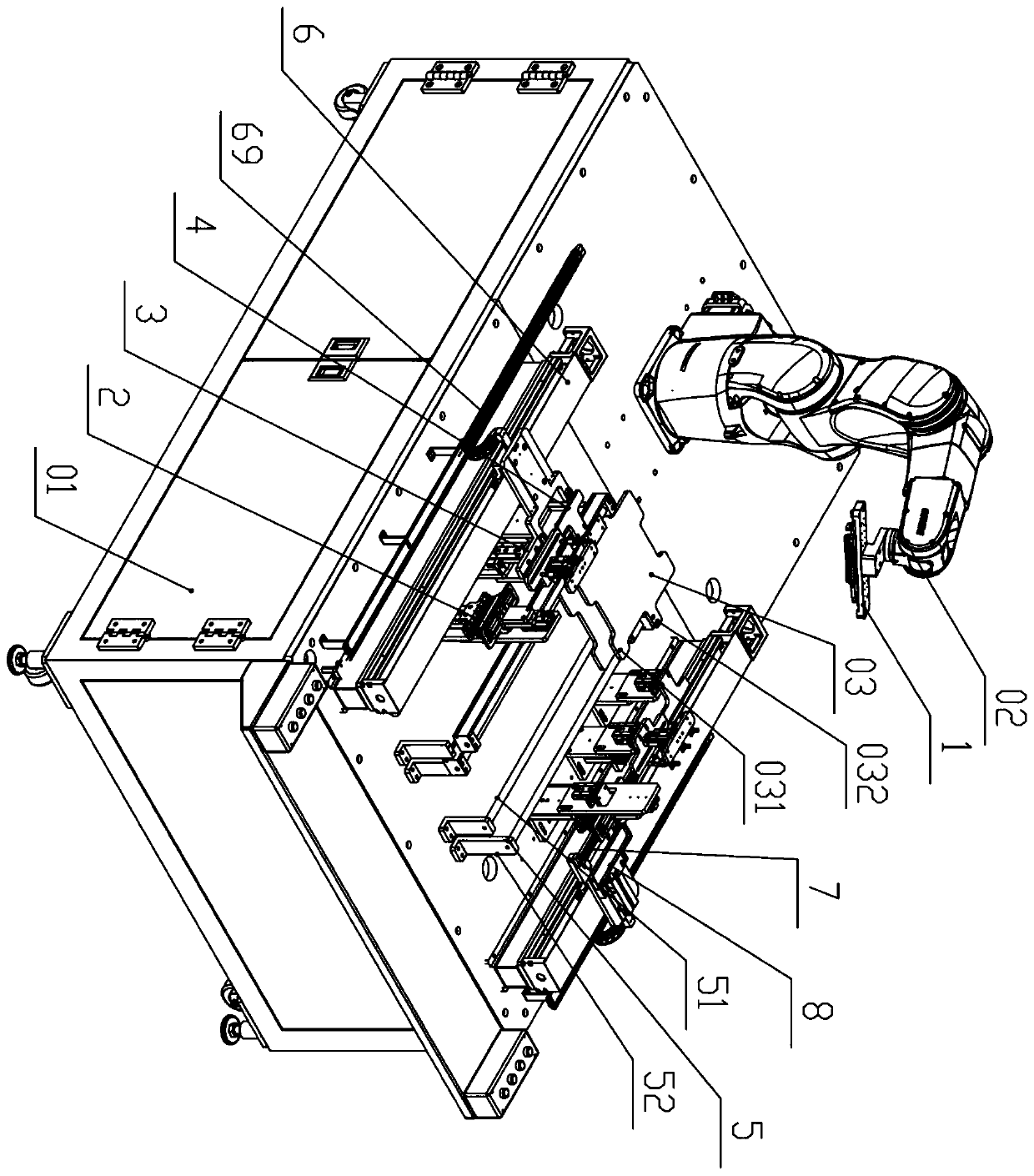

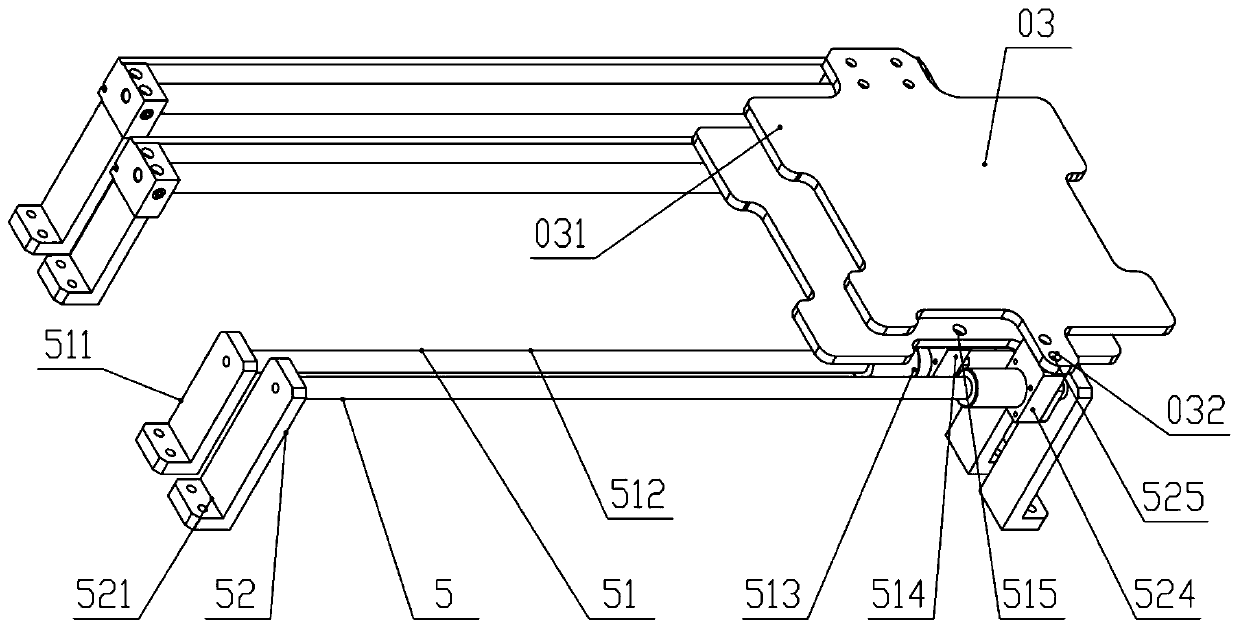

[0038] Figure 1 to Figure 15 A high-efficiency automatic film tearing machine according to an embodiment of the present invention is schematically shown. As shown in the figure, the device includes a rack 01, a manipulator 02 is installed in the center of the table of the rack 01, the manipulator 02 is equipped with a gripper fixture 1, and a temporary storage rack 5 is provided under the manipulator 02, and the temporary storage rack 5 can place materials. Tray 03, a moving part 6 is provided on the side of the temporary storage rack 5, and the moving part 6 can drive the material plate 7 and the waste film recovery plate 8 to move in a straight line. film, one side of the moving part 6 is sequentially arranged with a tearing film part 2 on both sides, a middle film part 3 and a film pressing part 4. There are two rows of first suction nozzles 25 and two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com