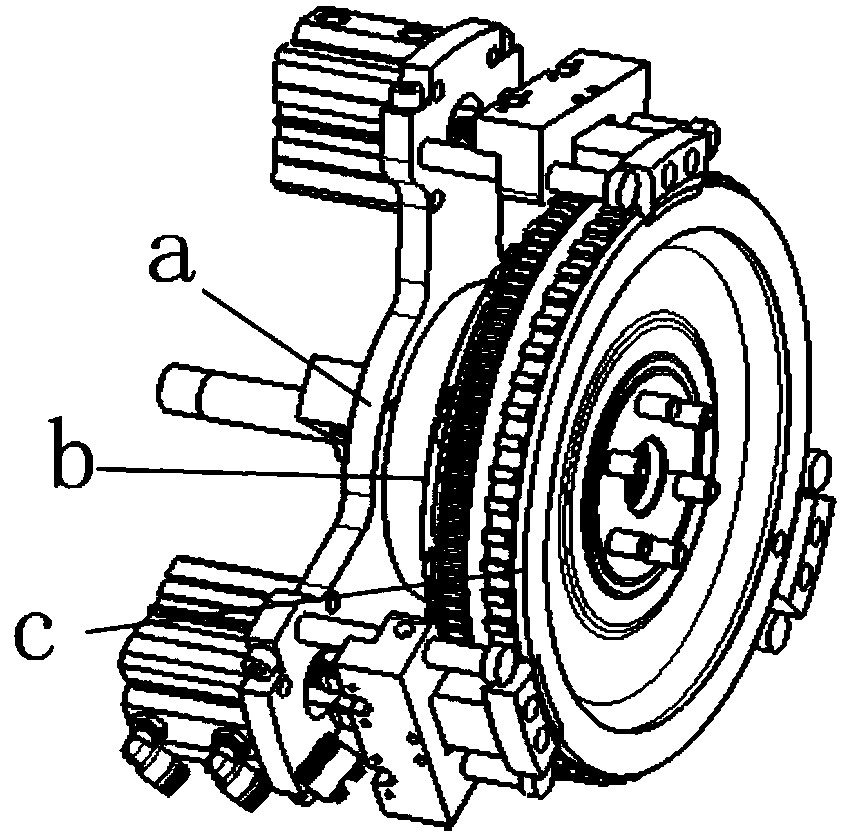

Tool for clutch assembly

A clutch and tooling technology, which is applied in the direction of manufacturing tools, workpiece clamping devices, hand-held tools, etc., can solve the problems of inability to ensure clutch installation accuracy, low assembly efficiency, and unequal planes between the pressure plate and the friction plate, and improve assembly efficiency. and accuracy, reasonable tooling structure design, and the effect of avoiding the problem of torque attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

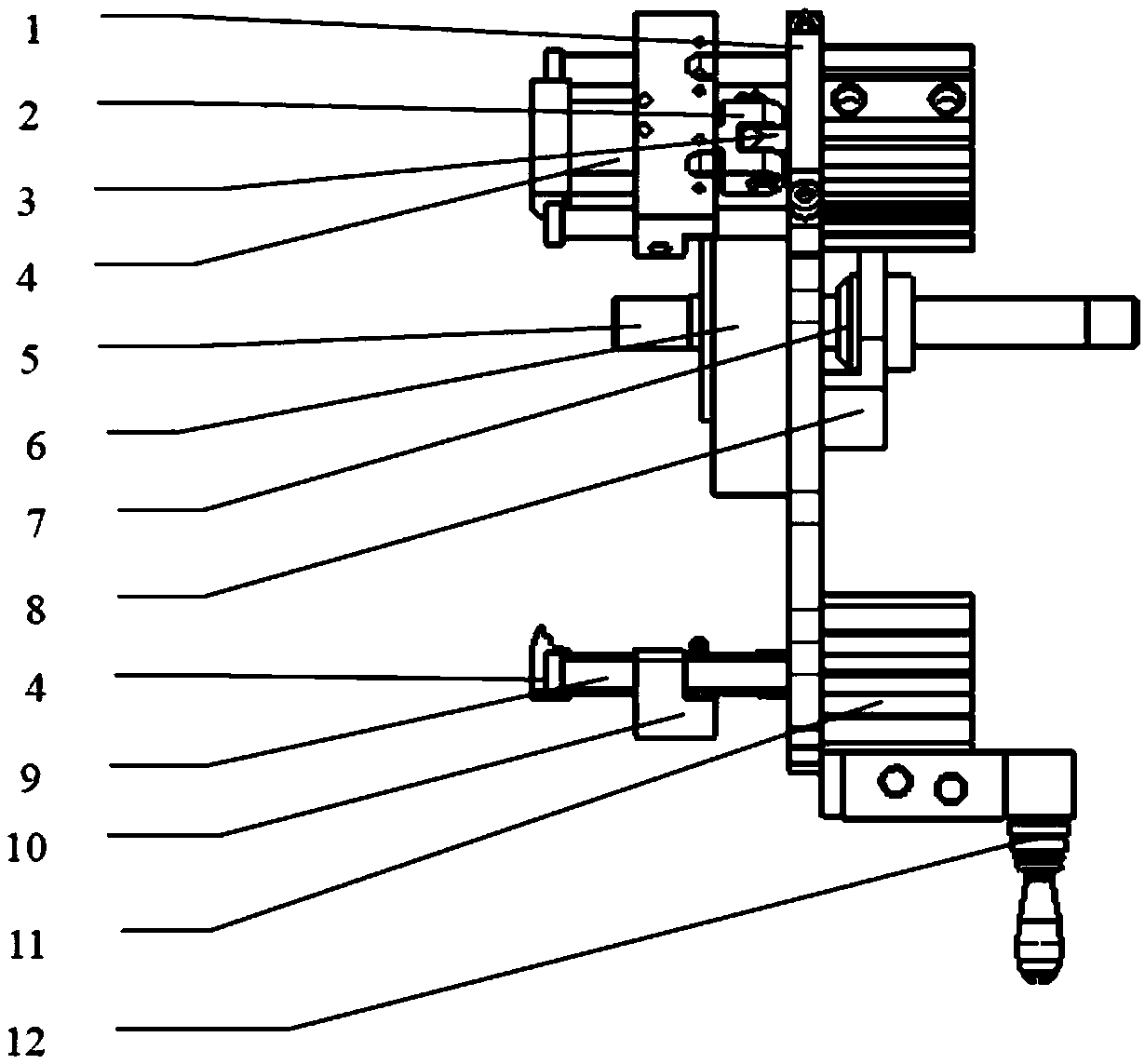

[0033] The supporting plate of the tooling is set into three convex plates, and the structure between the convex plates is arranged to form an angle of 120 degrees. The installation hole of the air cylinder is provided with an adjustment spring on the centering spline shaft support frame.

[0034] The stroke design of the limit guide rod is set based on the free state of the clutch and the installation height of the assembled state. When the clutch is in the free state, the limit guide rod is at the maximum stroke to facilitate the assembly of the centered spline shaft; when the clutch is assembled state, the limit guide rod is at the minimum stroke so that the clutch installation end face can fully fit the flywheel step surface.

[0035] The function of the slider is to switch the fixed claw between the free state and the clamped state; in the free state, the slider is at the forefront of the limit guide rod, that is, the fixed claw is in a freely open state; in the clamped s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com