Taiping kowkui automatic processing integrated machine

An all-in-one machine and Taiping technology, which is applied in the field of Taiping Houkui automatic processing all-in-one machine, can solve the problems of poor tea quality and low production efficiency, and achieve the effects of simple structure, improved quality, and accelerated separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

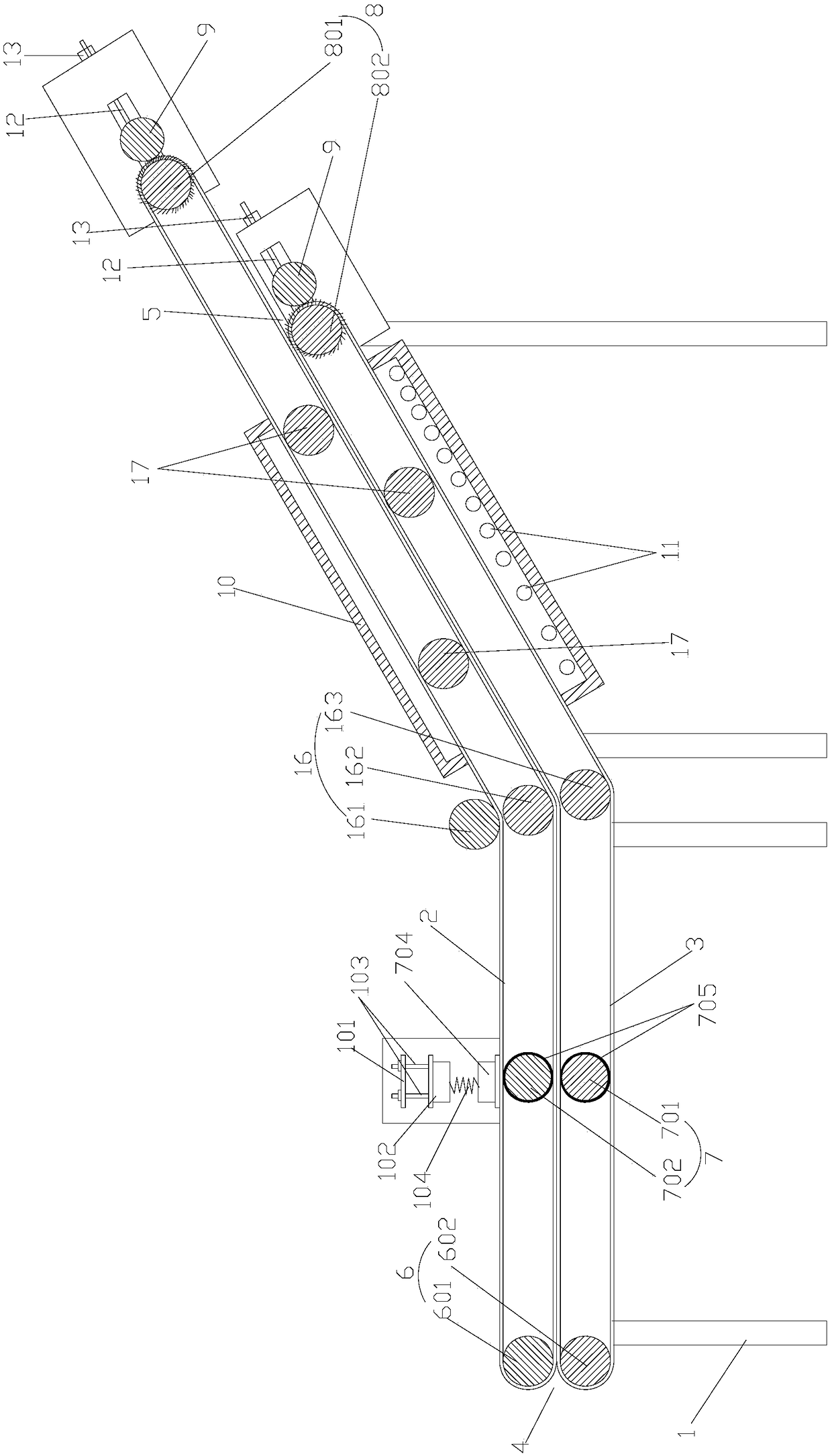

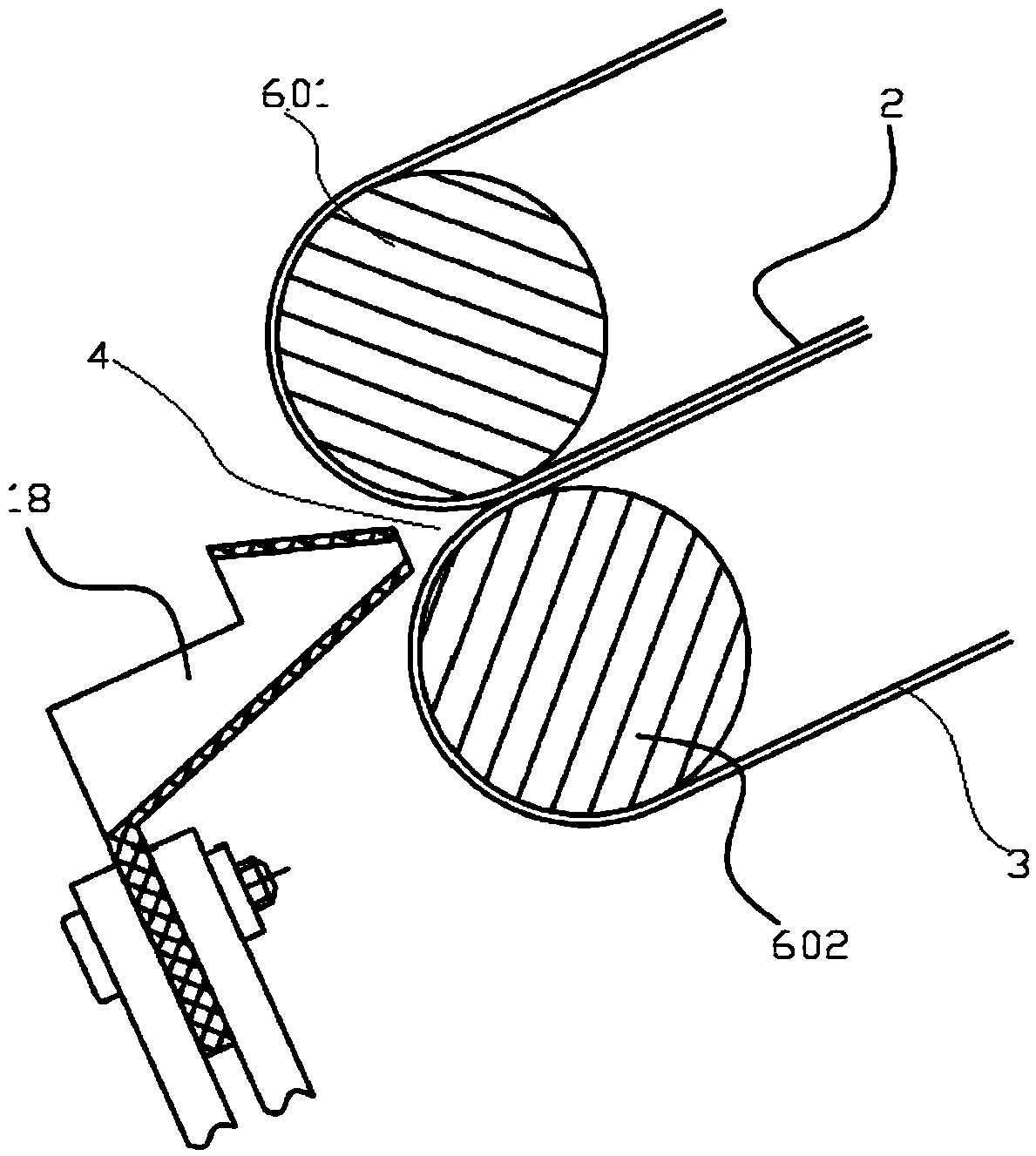

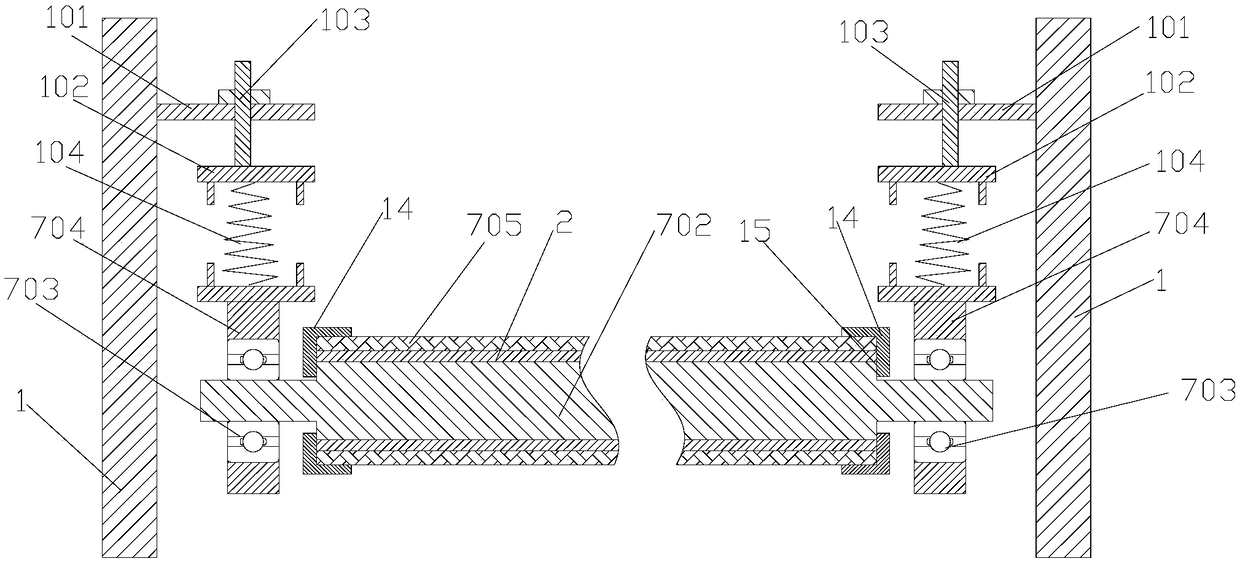

[0019] Examples such as Figures 1 to 4 As shown, a Taiping Houkui automatic processing integrated machine includes a frame 1, an upper rotary conveyor belt 2 and a lower rotary conveyor belt 3 arranged on the frame 1 and superimposed up and down, and the upper rotary conveyor belt 2 and the lower rotary conveyor belt The surfaces between adjacent belt surfaces of the rotary conveyor belt 3 are arranged in close contact with each other and have a mesh belt structure, and further, a steel wire mesh belt structure. One end of the upper rotary conveyor belt 2 and the lower rotary conveyor belt 3 is a tea inlet 4 , and the other end is a tea outlet 5 . One end of the tea feed inlet 4 is provided with a tea feeding device 18, such as figure 2 mentioned. Described tea feed inlet 4 places are provided with shaping roller group 6, and shaping roller group 6 comprises the upper shaping roller 601 that is arranged on the upper rotary conveyor belt 2 and the lower shaping roller 602 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com