Distiller's grain protein compound beverage and preparation method thereof

A technology of distiller's grain protein and beverages, which is applied in the direction of milk preparations, dairy products, applications, etc., can solve the problems of easy deterioration and many chemical additives, and achieve the effects of easy digestion and absorption, improving immunity, and increasing protein yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

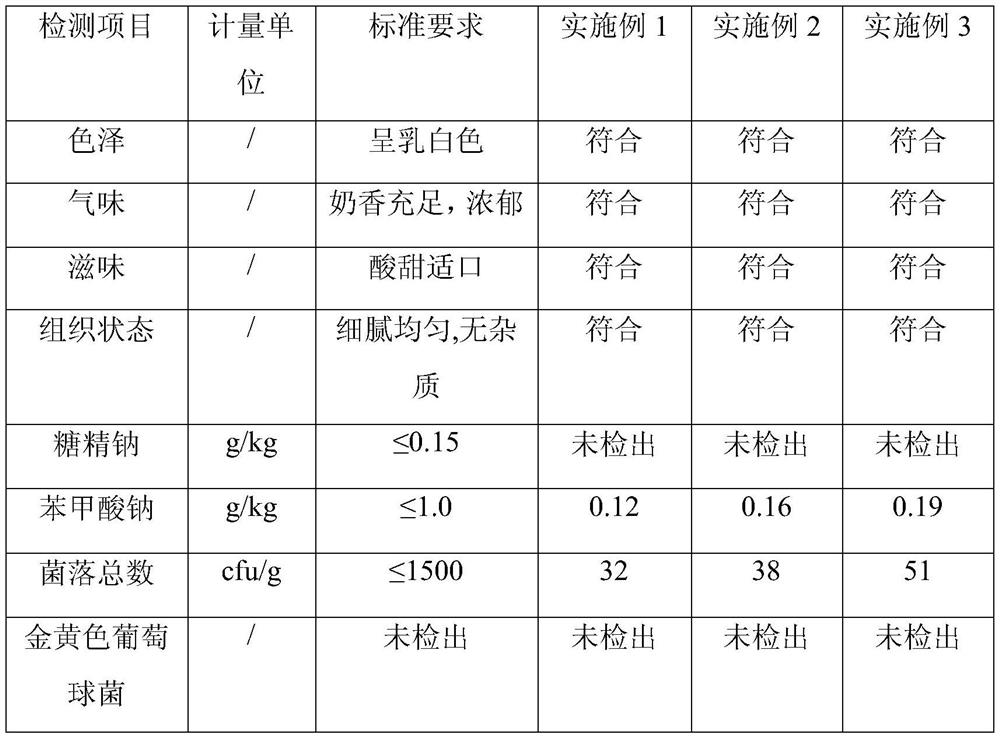

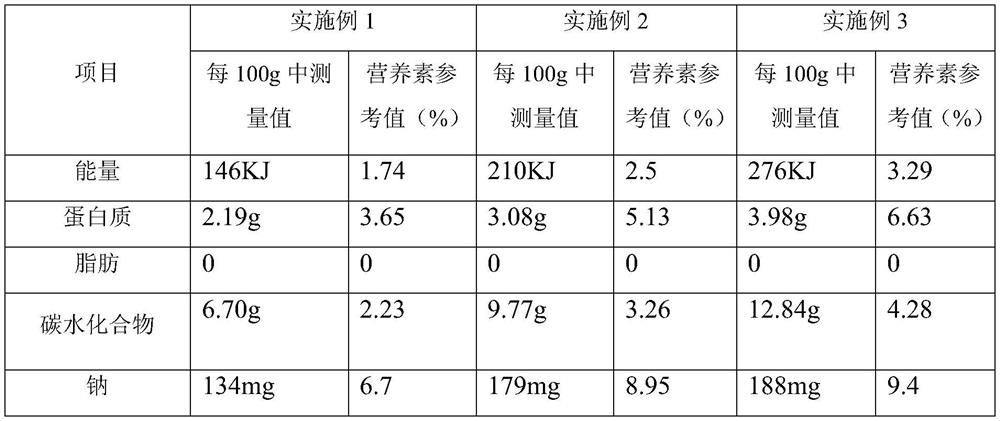

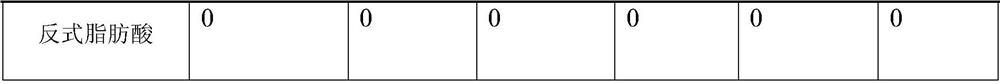

Examples

specific Embodiment approach 1

[0026] Specific Embodiment 1: The distiller's grain protein compound beverage of this embodiment consists of 1-2 parts of distiller's grain protein, 3-5 parts of skimmed milk powder, 5-10 parts of sucrose, 4-6 parts of honey, and 0.03-0.07 parts of sucrose in parts by mass. ester, 0.04-0.08 parts of xanthan gum, 0.02-0.05 parts of CMC-Na, 0.01-0.02 parts of sodium benzoate and 75-85 parts of purified water.

specific Embodiment approach 2

[0027] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the preparation method of described distiller's grain protein is carried out according to the following steps:

[0028] 1. Take the dehydrated and dried distiller's grains and crush them through a 60-mesh sieve to obtain distiller's grains powder; then add ethanol to sodium hydroxide at a volume ratio of 1: (2.5 to 3.5) and dissolve sodium hydroxide in ethanol to obtain a mixed solution;

[0029] 2. According to the volume ratio of distiller's grain powder to the mixed liquid: 1: (10-12), add distiller's grain powder to the mixed liquid, ultrasonically treat it at 30-35°C for 30-35 minutes, and then keep the temperature at 40-45°C After bathing in water for 90-120 minutes, put it into a centrifuge for centrifugation, take the supernatant and filter to obtain a protein extract;

[0030] 3. Adjust the pH of the protein extract to 6.4-6.6. After standing still, a precipitate...

specific Embodiment approach 3

[0032] Embodiment 3: This embodiment differs from Embodiment 2 in that the speed of the centrifuge in step 2 is 3000r / min-4000r / min, and the centrifugation time is 10-15min; the others are the same as Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com