A kind of preparation method of nickel-cobalt-aluminum ternary cathode material

A positive electrode material, nickel-cobalt-aluminum technology, applied in the field of lithium-ion battery preparation, can solve problems such as uneven mixing of ternary precursors and lithium sources, affecting the performance and life of lithium-ion batteries, and difficulty in forming large spherical particles. The effect of shortening the reaction time, reducing energy consumption, and increasing the concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

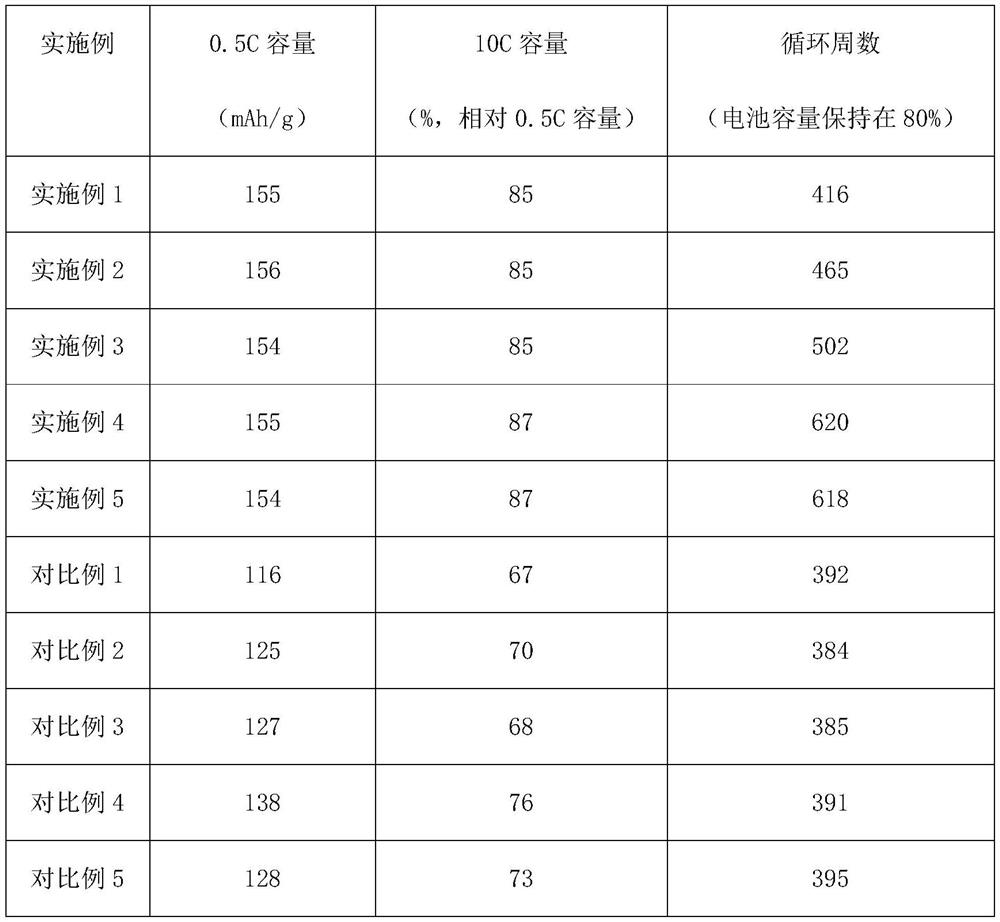

Examples

Embodiment 1

[0031] Drop 500ml of 0.5mol / L nickel sulfate solution, 500ml of 0.5mol / L cobalt nitrate solution, 500ml of 0.5mol / L aluminum chloride solution and 1200ml of 0.5mol / L ammonia water into a sealed container at the same time, and keep stirring , pressurize the container, adjust the pressure to 0.2MPa, react at normal temperature until no precipitation is generated, record the time, wash, filter, and dry to obtain the nickel-cobalt-aluminum precursor; combine the obtained nickel-cobalt-aluminum precursor with Lithium carbonate is mixed to obtain a mixture, and ethanol and glucose are added to the mixture, stirred into a slurry, then put into a high-temperature furnace, and at the same time, pure oxygen is introduced into the high-temperature furnace, sintered at 550°C for 12 hours, and then sintered at 700°C for 12 hours, and sintered Completely obtain the nickel-cobalt-aluminum ternary positive electrode material, wherein the material mass ratio Li / (Ni+Co+Al) of lithium element in ...

Embodiment 2

[0033]500ml of nickel nitrate solution of 0.5mol / L, 500ml of cobalt nitrate solution of 0.5mol / L, 500ml of aluminum nitrate solution of 0.5mol / L and 1200ml of ammonia water of 0.5mol / L were dropped into the sealed container respectively at the same time, constantly stirring, Pressurize the container, adjust the pressure to 0.3MPa, react at room temperature until no precipitation is formed, record the time, wash, filter, and dry to obtain the nickel-cobalt-aluminum precursor; mix the obtained nickel-cobalt-aluminum precursor with carbonic acid Mix lithium to obtain a mixture, add ethanol and glucose to the mixture, stir it into a slurry, then put it into a high-temperature furnace, and at the same time feed pure oxygen into the high-temperature furnace, sinter at 550°C for 12 hours, turn to 700°C for 12 hours, and sinter completely Afterwards, the nickel-cobalt-aluminum ternary positive electrode material is obtained, wherein the mass ratio Li / (Ni+Co+Al) of the lithium element i...

Embodiment 3

[0035] Drop 500ml of 0.5mol / L nickel sulfate solution, 500ml of 0.5mol / L cobalt sulfate solution, 500ml of 0.5mol / L aluminum chloride solution and 1200ml of 0.5mol / L ammonia water into a sealed container at the same time, and keep stirring , pressurize the container, adjust the pressure to 0.4MPa, react at normal temperature until no precipitation is generated, record the time, wash, filter, and dry to obtain the nickel-cobalt-aluminum precursor; the obtained nickel-cobalt-aluminum precursor and Lithium carbonate is mixed to obtain a mixture, and ethanol and glucose are added to the mixture, stirred into a slurry, then put into a high-temperature furnace, and at the same time, pure oxygen is introduced into the high-temperature furnace, sintered at 550°C for 12 hours, then sintered at 700°C for 12 hours, and sintered Completely obtain the nickel-cobalt-aluminum ternary positive electrode material, wherein the material mass ratio Li / (Ni+Co+Al) of lithium element in lithium carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com