High-resolution object space telecentric system based on machine vision

An object-space telecentric, high-resolution technology, applied in instruments, optical components, optics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

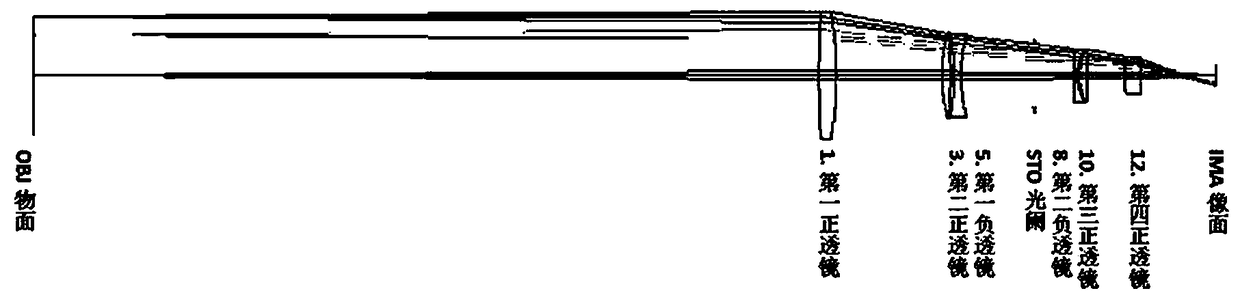

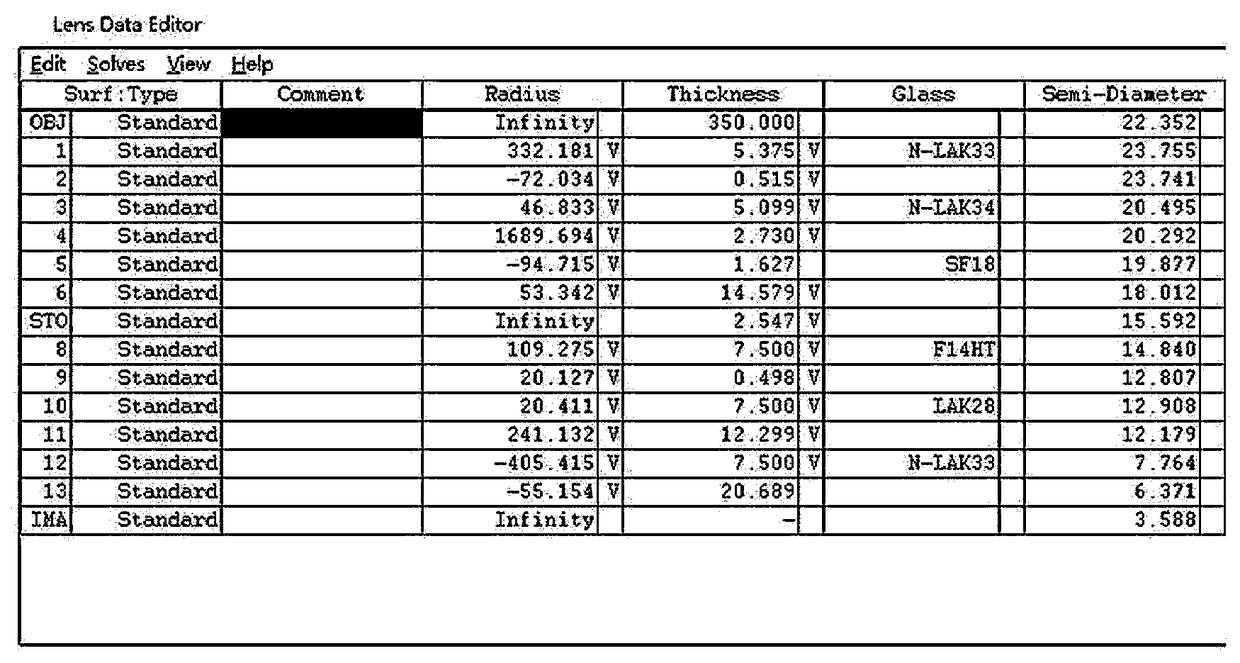

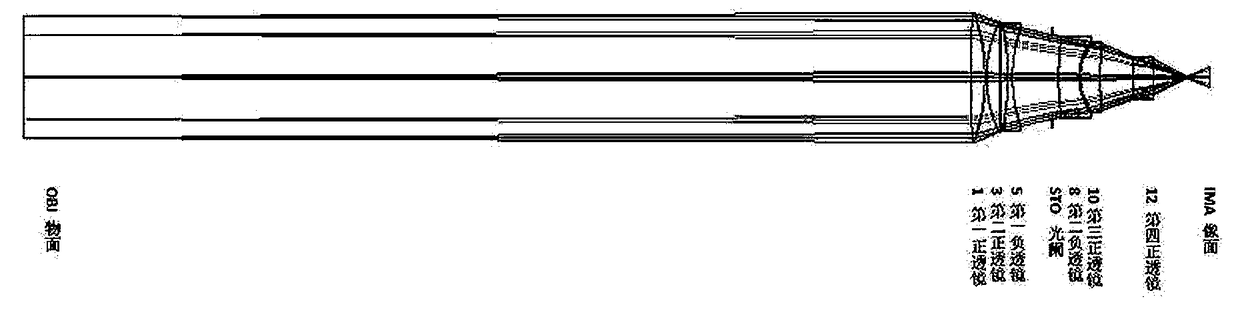

[0032] refer to figure 1 , a high-resolution object-space telecentric system based on machine vision, including a first positive lens, a second positive lens, a first negative lens, an aperture surface, a second negative lens, and a third positive lens arranged sequentially from the incident direction of light and the fourth positive lens, each of the lenses and the aperture surface are coaxial with the center of the object plane, and the distance from the apex of the first positive lens to the object plane is the working distance.

[0033] The thickness of the first positive lens is 5.38mm, the thickness of the second positive lens is 5.10mm, the thickness of the first negative lens is 1.63mm, the thickness of the second negative lens is 7.50mm, the thickness of the third positive lens is 7.50mm, and the thickness of the fourth positive lens The lens thickness is 7.50mm.

[0034] The distance from the first positive lens to the second positive lens is 0.52mm; the distance fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com