Loading device and method for bond slip performance test

A loading device and bond-slip technology, applied in the direction of using mechanical devices, measuring devices, instruments, etc., can solve the problems of reduced loading accuracy, reduced test accuracy of bond-slip performance, and inability to release loading connection bending moment, etc. Achieve the effect of improving accuracy, improving loading efficiency, and enhancing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

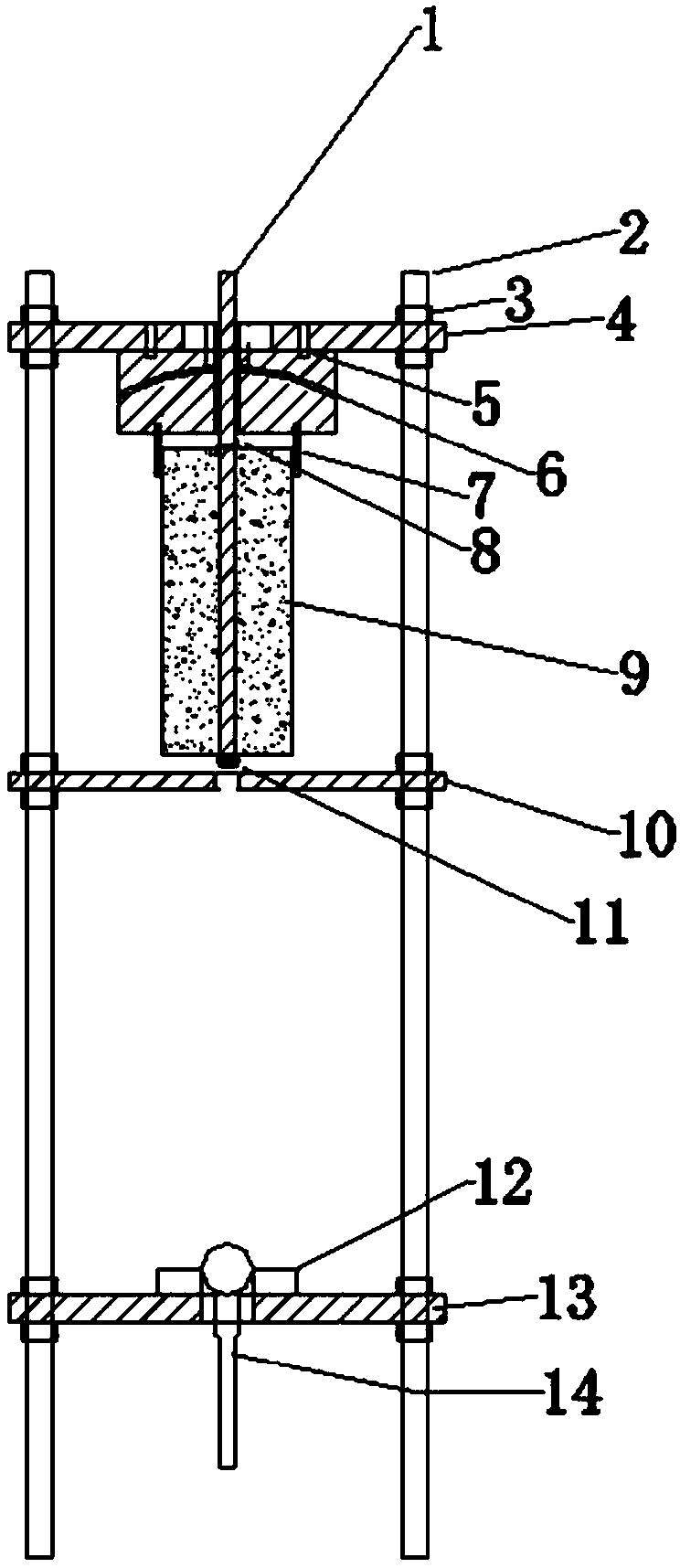

[0043] refer to Figure 1 to Figure 12 , a loading device for bond-slip performance test of the present invention, comprising: a loading frame, a test piece and a testing machine.

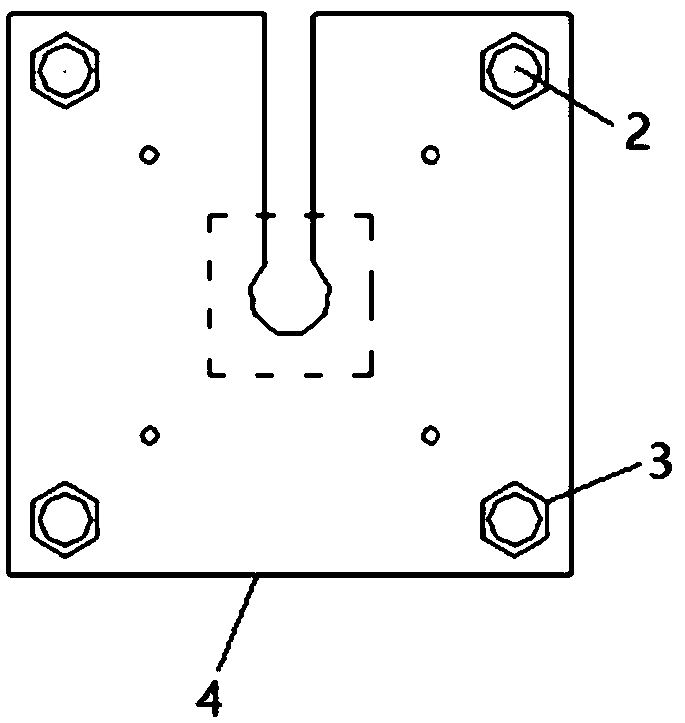

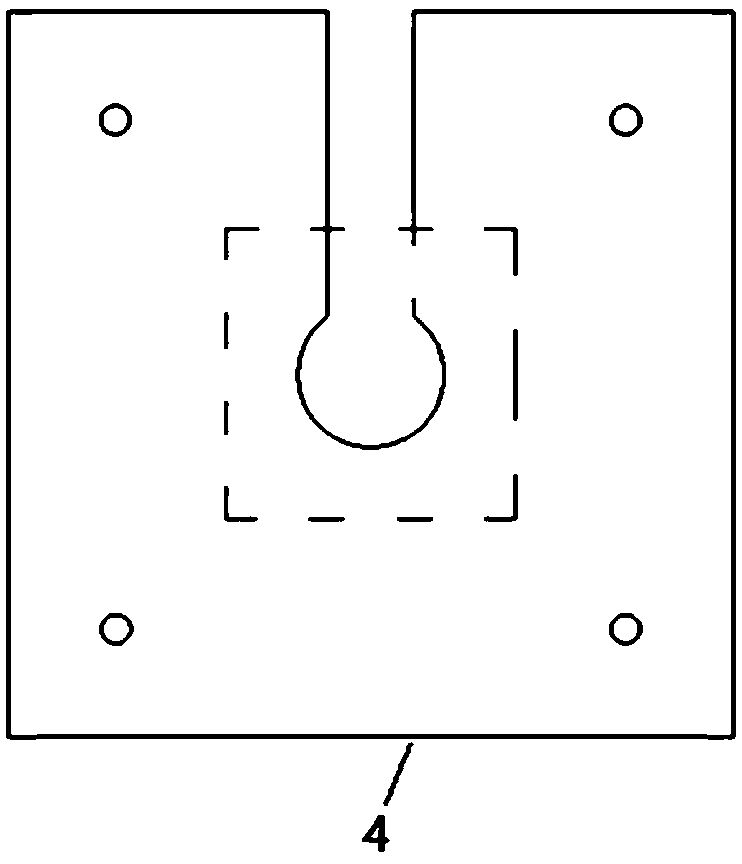

[0044]The loading frame comprises legs, a first support plate 4, a second support plate 10 and a third support plate 13, and the first support plate 4, the second support plate 10 and the third support plate 13 are fixedly arranged on the legs in sequence; The legs are four screw rods 2, and the three support plates are all rectangular steel plates. There are corresponding coaxial threaded mounting holes near the four corners of the three support plates. For fixed connection, the screw rod 2 is used as the leg to adjust the distance between the first support plate 4 and the second support plate 10 according to the length of the test piece, which is conven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com