Mine downhole dust monitoring and control system

A control system and underground mine technology, applied in dust prevention, mining equipment, measuring devices, etc., can solve problems such as wasting water resources, coal loss, affecting the measurement accuracy of dust concentration, etc., and achieve the effect of expanding the scope of dust suppression and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

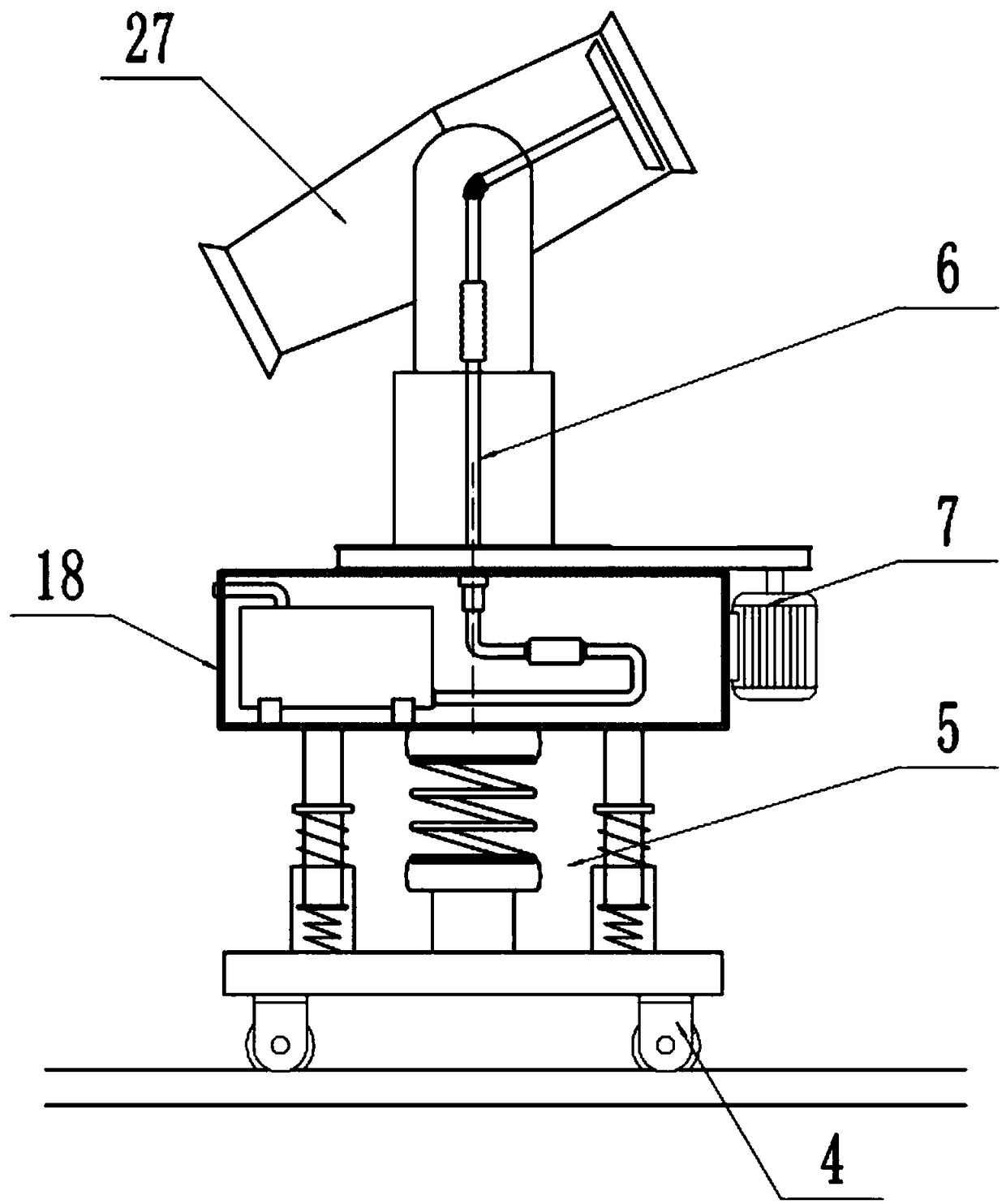

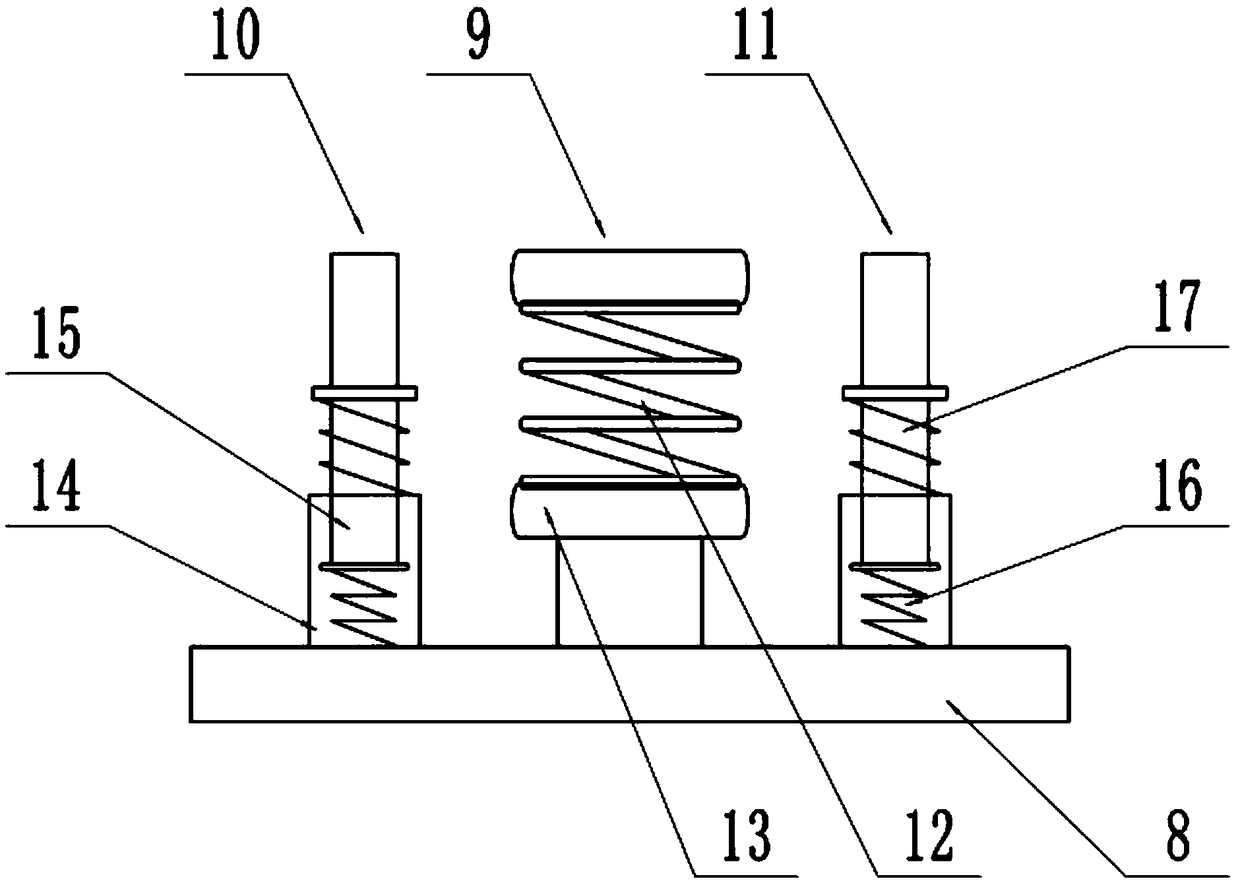

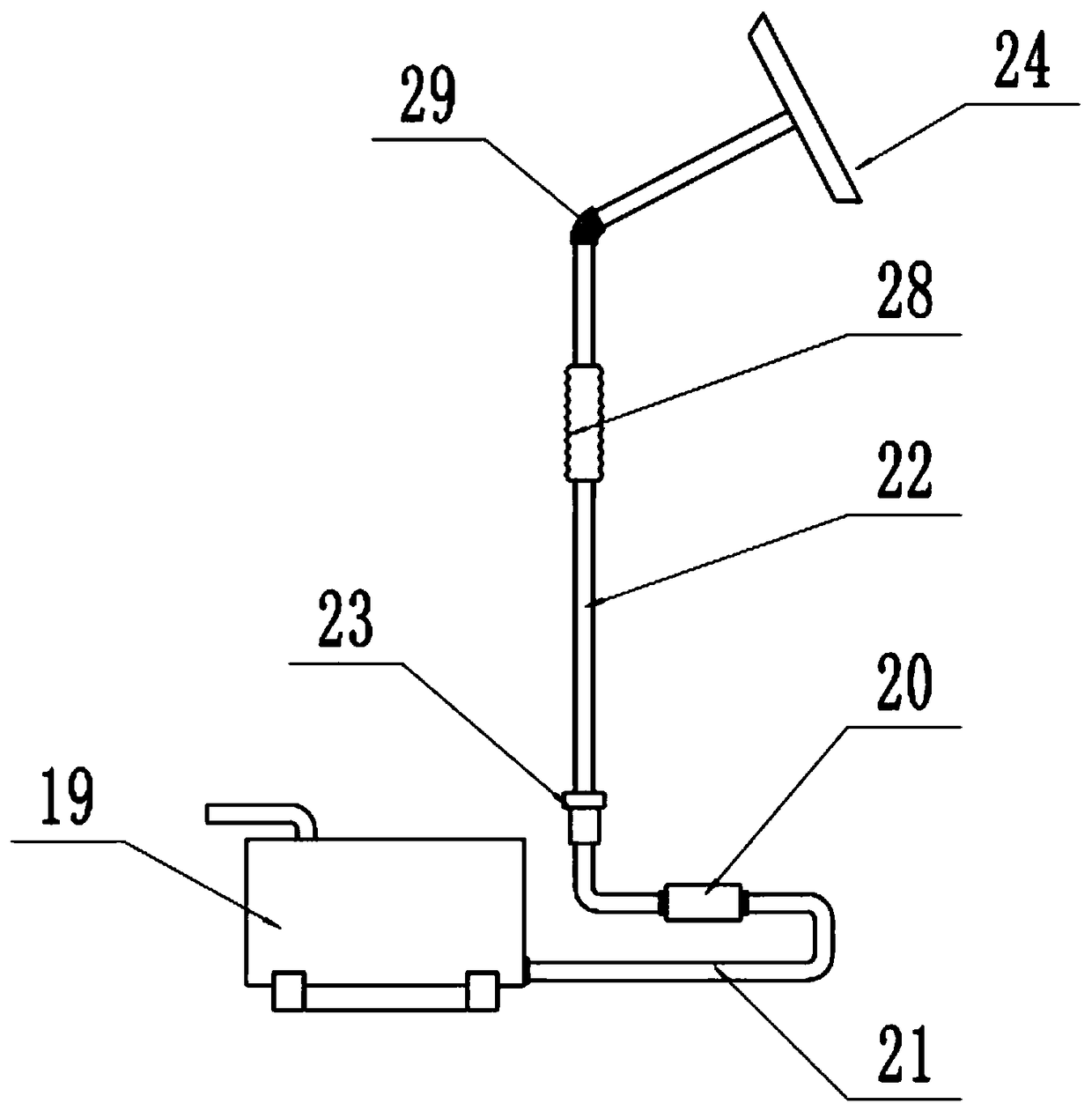

[0022] The present invention is realized through the following technical solutions:

[0023] An underground dust monitoring and control system, including a dust monitoring module and a dust elimination module, the dust monitoring module is used to monitor the underground dust concentration in real time, and transmits its specific data to the switchboard, the dust elimination module is installed underground, For reducing the downhole dust concentration value, the dust monitoring module includes a dust concentration sensor 1, a position sensor 2 and a single-chip microcomputer 3, and the dust concentration sensor 1 and the position sensor 2 are distributed at multiple monitoring points downhole, and are used for Detect the dust concentration and determine the specific position of the dust concentration at each monitoring point; the output ends of the dust concentration sensor 1 and the position sensor 2 are all connected to the input end of the single-chip microcomputer 3; the du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com