A Downhole Intelligent Control Integrated Injection Device

An intelligent control and injection technology, applied in the direction of wellbore/well components, measurement, production fluid, etc., can solve the problems of shortening the total length of tools, many cable connection points, complex on-site operation, etc., to save testing costs, The effect of improving accuracy and simplifying the inspection and sealing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

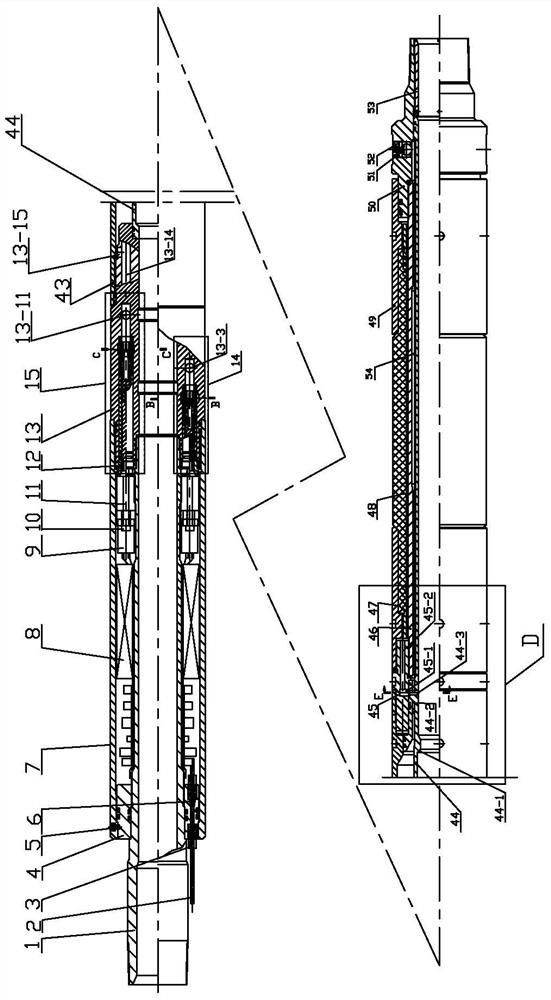

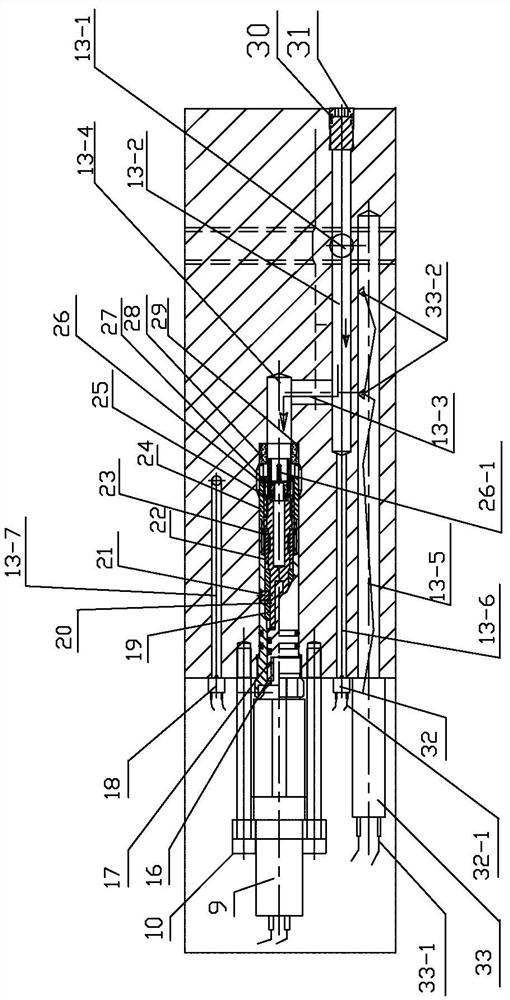

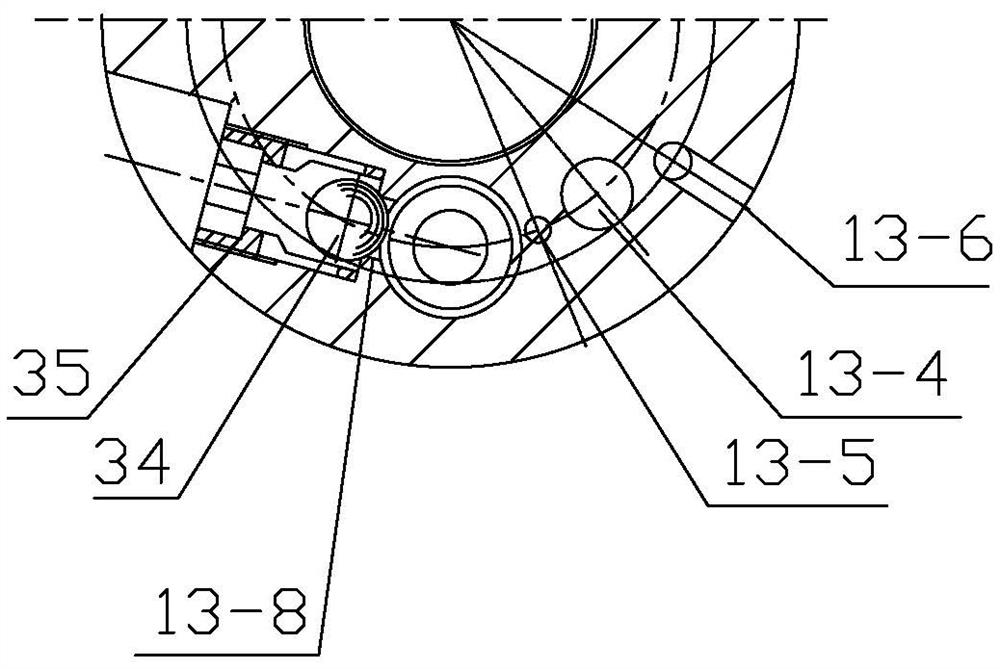

[0024] like Figure 1-Figure 7 Shown is the downhole intelligent control integrated injection device of the present invention, including an upper joint 1, a sealing body 13, a composite inner pipe 44 and a lower joint 50 connected in sequence. It is sealingly connected with the outer periphery of the sealing body 13 , a middle connecting sleeve 43 is arranged on the outer periphery of the lower side of the sealing body 13 , a liquid inlet valve 45 is arranged between the composite inner pipe 44 and the middle connecting sleeve 43 , and the inner periphery of the lower side of the liquid inlet valve 45 is connected. There is a middle sealing pipe 46, and an expansion packer is arranged on the lower side of the liquid inlet valve 45; two sets of metering mechanisms and water distribution mechanisms are arranged in parallel in the annular perip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com