Plant culture medium for roof greening and preparation method thereof

A roof greening and cultivation substrate technology, applied in fertilizers, applications, and fertilizer mixtures made of biological waste, can solve problems such as occupying a large amount of land and environmental pollution, and achieve the effects of moderate load, good water storage, and moderate pH.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

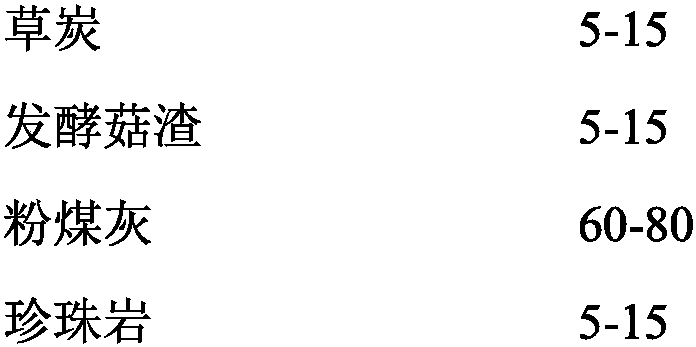

Method used

Image

Examples

Embodiment 1

[0058] 1. Preparation of fermented mushroom dregs

[0059] 1A) Pulverize the remaining mushroom dregs after harvesting edible fungi, and then spray water to adjust the moisture content of the mushroom dregs to 60% (usually 50%-65%, preferably 50-60%) to obtain pre-fermented mushrooms slag;

[0060] Mushroom dregs usually use fresh mushroom dregs, including Pleurotus eryngii dregs, shiitake mushroom dregs, Flammulina velutipes dregs, Pleurotus ostreatus dregs, etc.;

[0061] 1B) Pile the pre-fermented mushroom dregs in the fermentation tank, carry out stacking fermentation treatment, and monitor the temperature and moisture content of the pile;

[0062] The fermentation time is calculated from the time when the pre-fermented mushroom dregs are piled up in the fermentation tank. As the fermentation progresses, the temperature of the pile increases first and then decreases. ℃, preferably 60-65 ℃), turn the pile, spray water to the pile when turning, adjust the moisture content ...

Embodiment 2

[0084] 1. Preparation of fermented mushroom dregs

[0085] 1A) Pulverizing the mushroom dregs remaining after harvesting edible fungi, and then spraying water to adjust the moisture content of the mushroom dregs to 55% to obtain pre-fermented mushroom dregs;

[0086] 1B) Pile the pre-fermented mushroom dregs in the fermentation tank, carry out stacking fermentation treatment, and monitor the temperature and moisture content of the pile;

[0087] The fermentation time is calculated from the time when the pre-fermented mushroom dregs are piled up in the fermentation tank. As the fermentation progresses, the temperature of the pile increases first and then decreases. ℃, preferably 60-65 ℃), turn the pile, spray water to the pile when turning, adjust the moisture content of the pile to 55% (usually 50-60%), until the temperature of the pile is reduced to room temperature (usually 15-30°C, preferably 20-25°C), stop the fermentation treatment, and obtain the mushroom dregs fermenta...

Embodiment 3

[0096] 1. Preparation of fermented mushroom dregs

[0097] 1A) Pulverizing the mushroom dregs left after harvesting edible fungi, and then spraying water to adjust the moisture content of the mushroom dregs to 65% to obtain pre-fermented mushroom dregs;

[0098] 1B) Pile the pre-fermented mushroom dregs in the fermentation tank, carry out stacking fermentation treatment, and monitor the temperature and moisture content of the pile;

[0099] The fermentation time is calculated from the time when the pre-fermented mushroom dregs are piled up in the fermentation tank. As the fermentation progresses, the temperature of the pile increases first and then decreases. ℃, preferably 60-65 ℃), turn the pile, spray water to the pile when turning, adjust the moisture content of the pile to 60% (usually 50-60%), until the temperature of the pile is reduced to room temperature (usually 15-30°C, preferably 20-25°C), stop the fermentation treatment, and obtain the mushroom dregs fermentation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Ec value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com