Mixed arm type overhead working truck

A high-altitude working vehicle and boom-type technology, applied in the field of special vehicles, can solve the problem of low working height, and achieve the effects of reducing self-weight, reducing production and operating costs, and reducing the quality of the whole vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing description and specific embodiment, the present invention will be described in further detail:

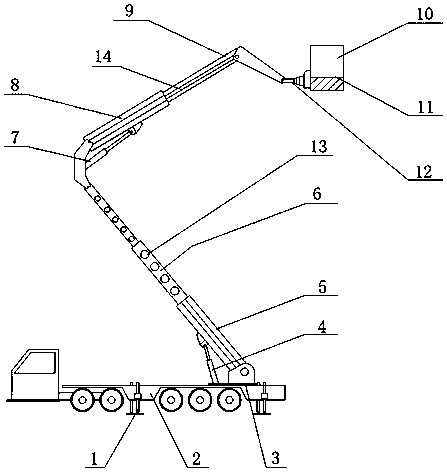

[0010] see figure 1 , a hybrid arm type aerial work vehicle, comprising a boarding part and a disembarking part, the boarding part includes a turntable 3, a lower luffing hydraulic cylinder 4, an upper luffing hydraulic cylinder 7, a lower main arm 5, an upper main arm 8, Lower telescopic arm 6, upper telescopic arm 9, work platform 10, work platform pedal 11 and work platform leveling mechanism 12. The getting off part comprises the automobile chassis 2, the hydraulic support leg 1 and the driver's cab and the like. The hydraulic outrigger 1 is set on the bottom of the automobile chassis 2, the turntable 3 is placed on the automobile chassis 2, the upper part rotates relative to the lower part, the lower main arm 5 is hinged on the rotary platform 3, and the lower luffing cylinder 4 is responsible for controlling the variable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com